High-speed rail heavy rail surface defect detection method based on point cloud method

A technology of defect detection and high-speed rail, which is applied in the direction of optical defect/defect test, measurement device, image data processing, etc., and can solve problems such as influence, easy missed detection and false detection, and limited image acquisition quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

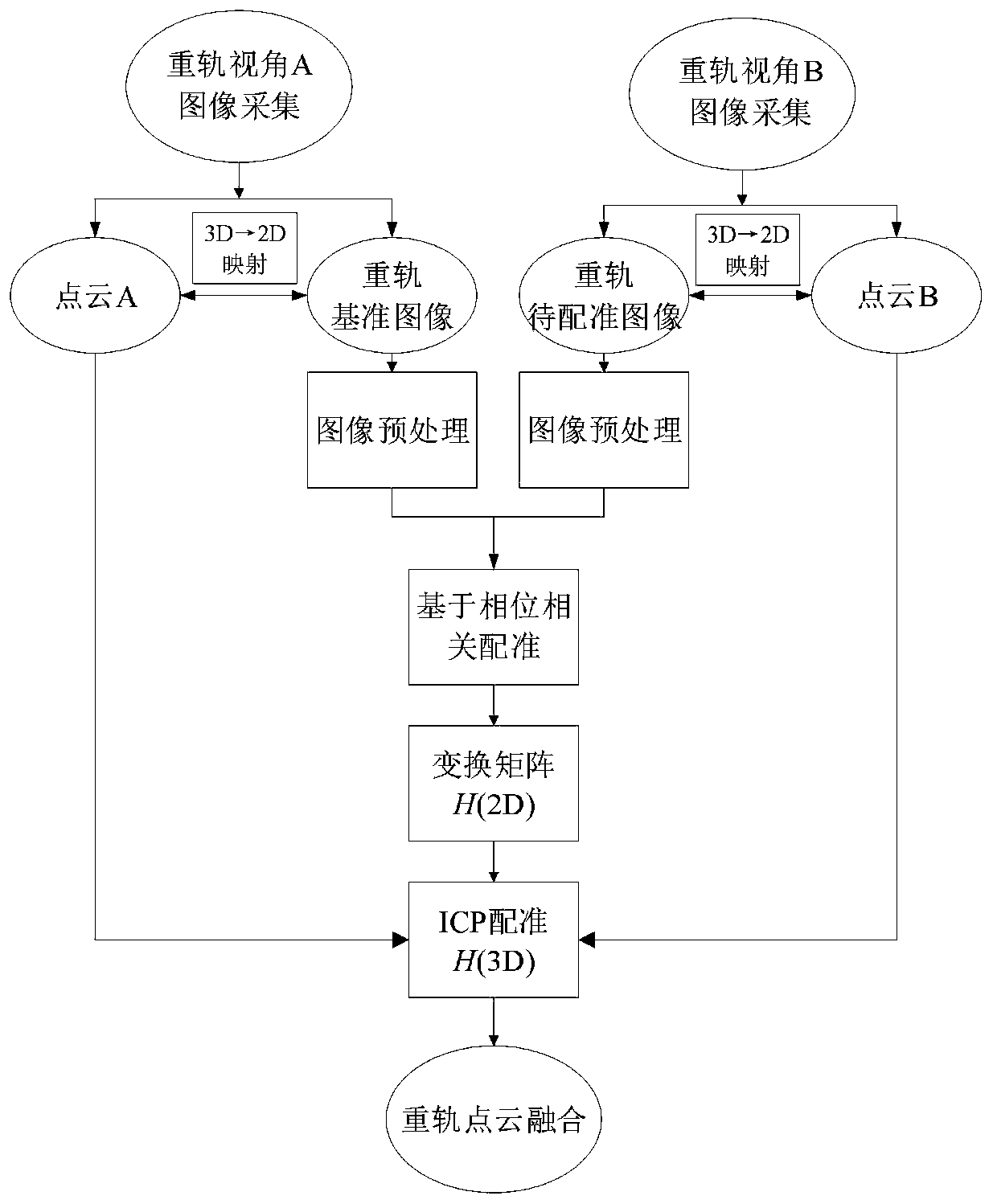

[0079] The surface defect detection method of high-speed rail and heavy rail based on the point cloud method of the present invention is characterized in that: comprising the following steps:

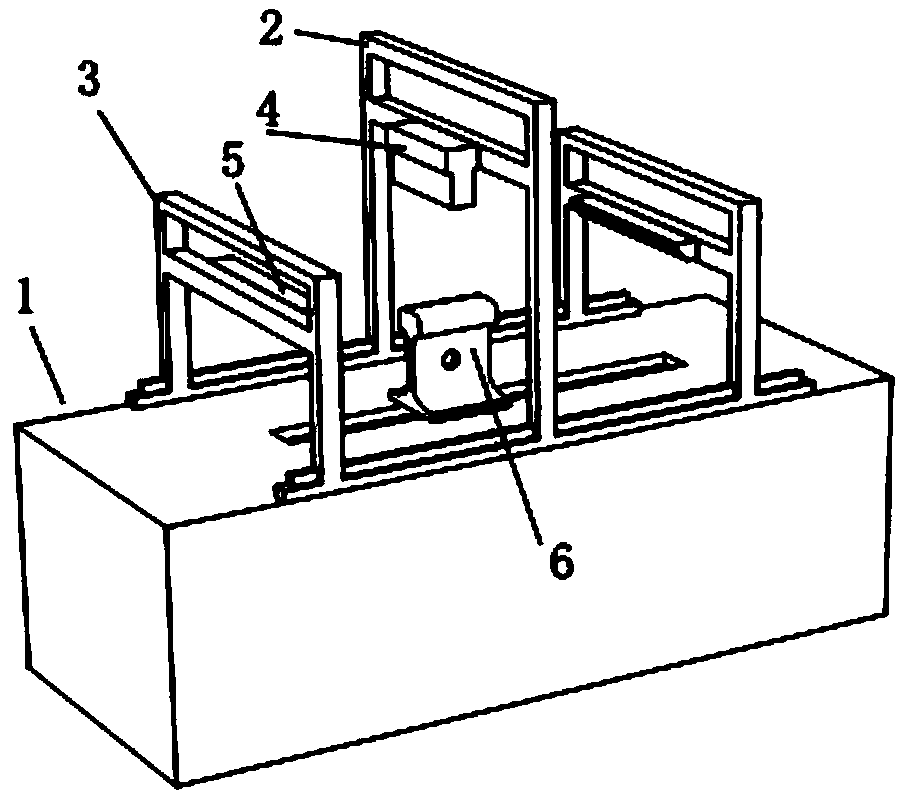

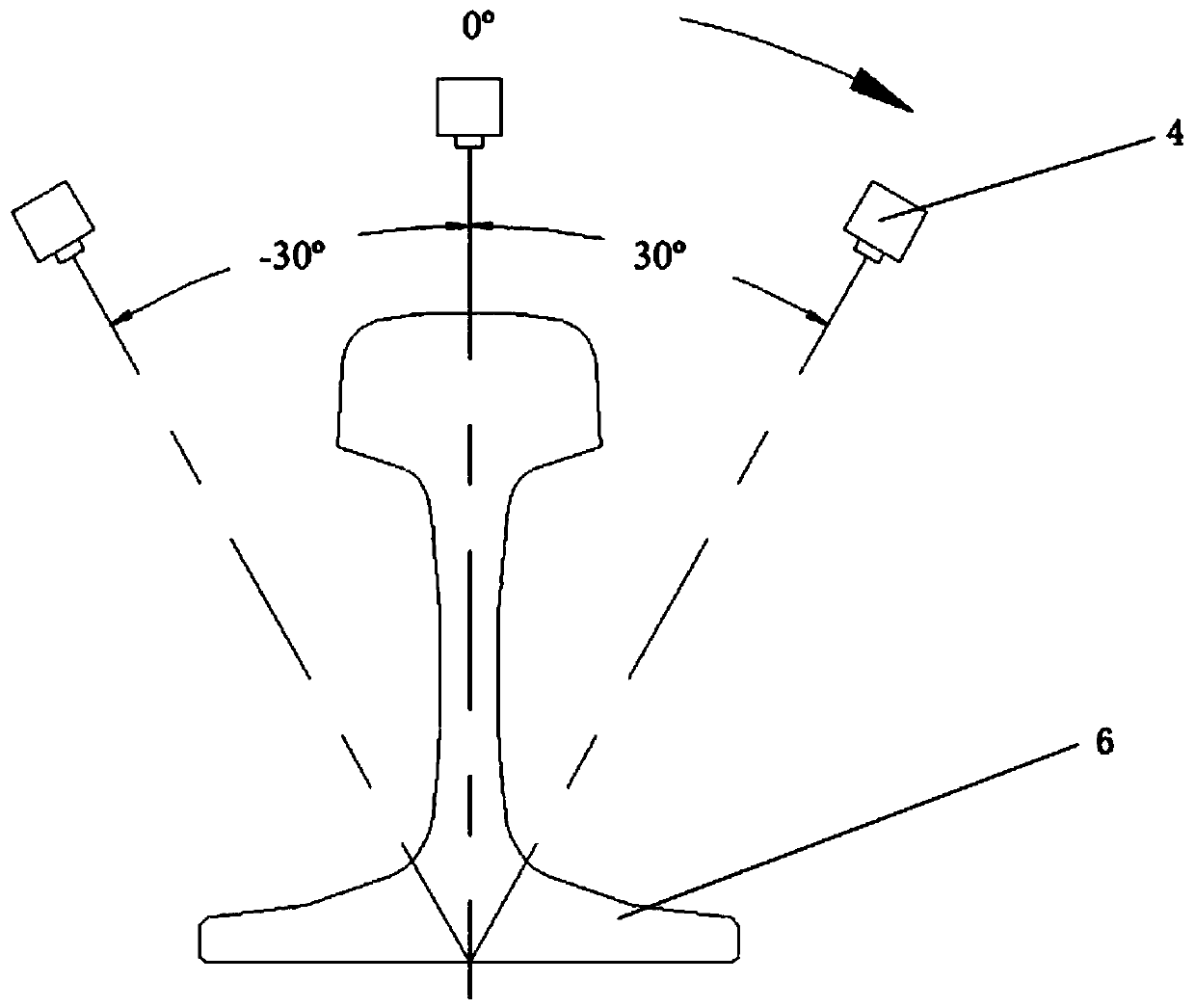

[0080] Step 1: Build a detection platform 1, the detection platform 1 is provided with an intermediate fixed frame 2, two fixed frames 3 on both sides symmetrical about the intermediate fixed frame 2, the detection platform 1 is provided with crawlers in the upper middle, A motor is arranged below, and the motor is used to control the speed of the crawler hub; a color binocular line array camera 4 is installed on the middle fixed frame 2, and a professional lighting device 5 is installed on the fixed frames 2 on both sides.

[0081] Step 2: Turn on the power of the detection platform 1, adjust the brightness of the professional lighting equipment 5, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com