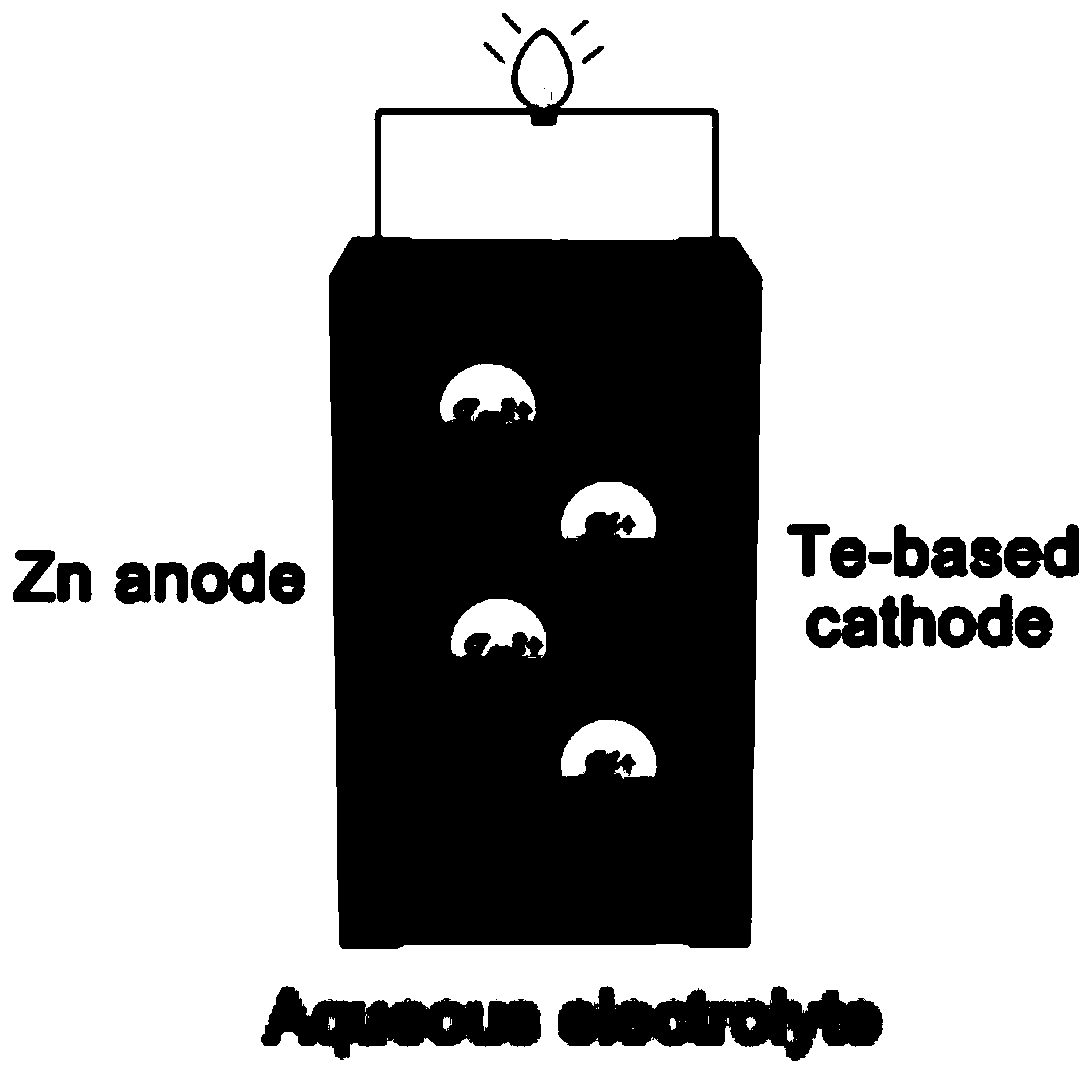

Aqueous zinc-tellurium secondary battery

A secondary battery and water system technology, applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problems of getting attention and in-depth research in the battery field, and achieve the effect of high capacity and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Electrolyte: 1mol / L aqueous solution of zinc sulfate.

[0049] Positive electrode: Use simple tellurium as the tellurium active material, mix the tellurium active material, conductive agent and binder at a mass ratio of 8:1:1, coat the surface of titanium foil, cut it into a certain size, and dry it in vacuum A tellurium positive electrode sheet was prepared. The conductive agent is conductive carbon black; the binder is polyvinylidene fluoride (PVDF).

[0050] Negative electrode: a zinc sheet with a thickness of 0.15mm.

[0051] A positive electrode sheet, a negative electrode, an aqueous solution of 1 mol / L zinc sulfate, and a separator between the positive electrode and the negative electrode are assembled into a battery; the separator: a glass fiber separator.

[0052] Perform performance tests on the above assembled electrodes:

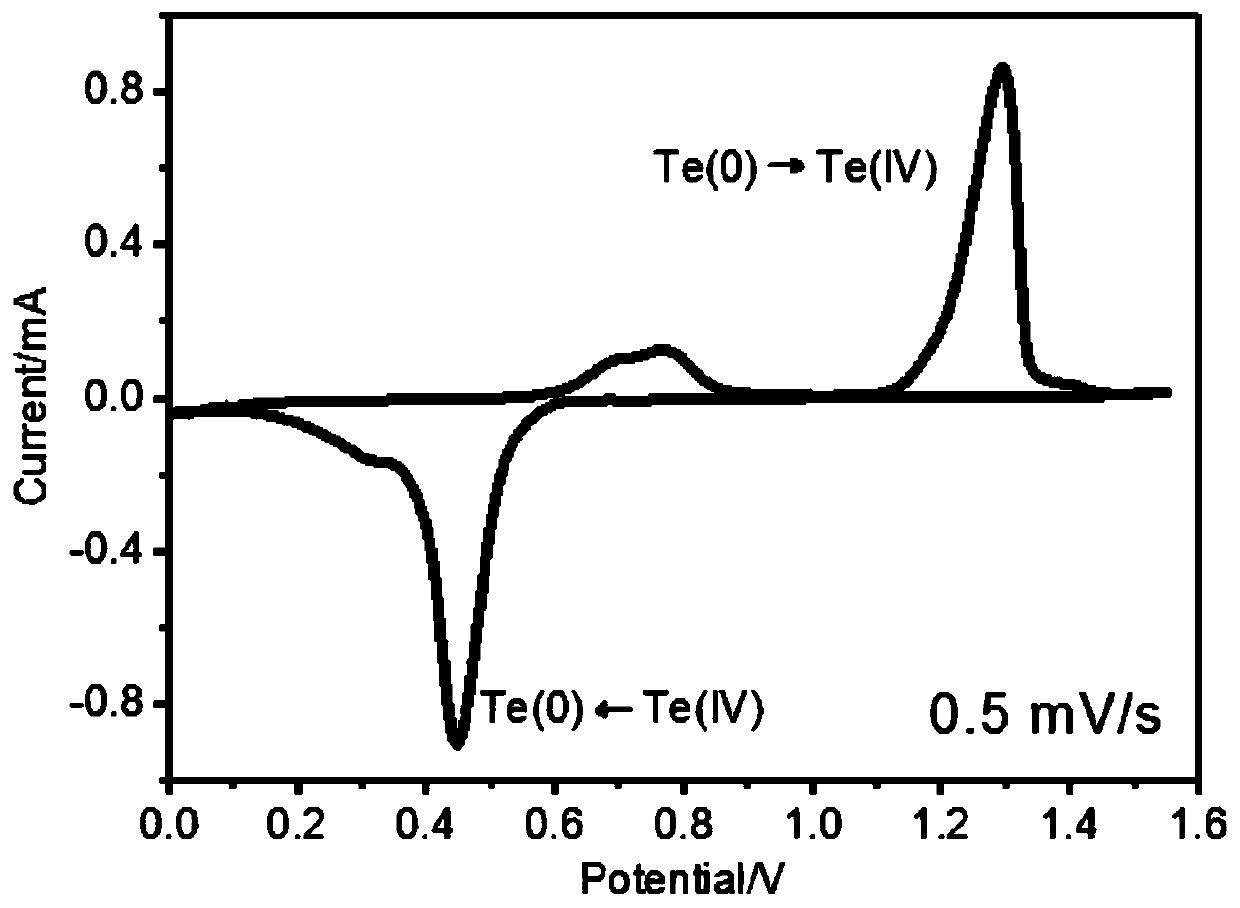

[0053] Depend on figure 2 It can be seen that a pair of obvious redox peaks appear in the cyclic voltammetry curve of the aqueous zi...

Embodiment 2

[0057] Electrolyte: 2mol / L zinc sulfate aqueous solution.

[0058] Positive electrode: tellurium dioxide is used as the tellurium active material, the tellurium active material, the conductive agent and the binder are mixed in a mass ratio of 6:3:1, coated on the surface of the titanium foil, cut into a certain size, and baked in a vacuum Dry the tellurium positive electrode sheet. The conductive agent is conductive carbon black; the binder is polyvinylidene fluoride (PVDF).

[0059] Negative electrode: zinc sheet with a thickness of 0.15mm;

[0060] A battery is assembled with a positive electrode sheet, a negative electrode, a 2mol / L zinc sulfate aqueous solution, and a separator between the positive electrode and the negative electrode; diaphragm: glass fiber diaphragm.

[0061] Perform performance tests on the above assembled electrodes:

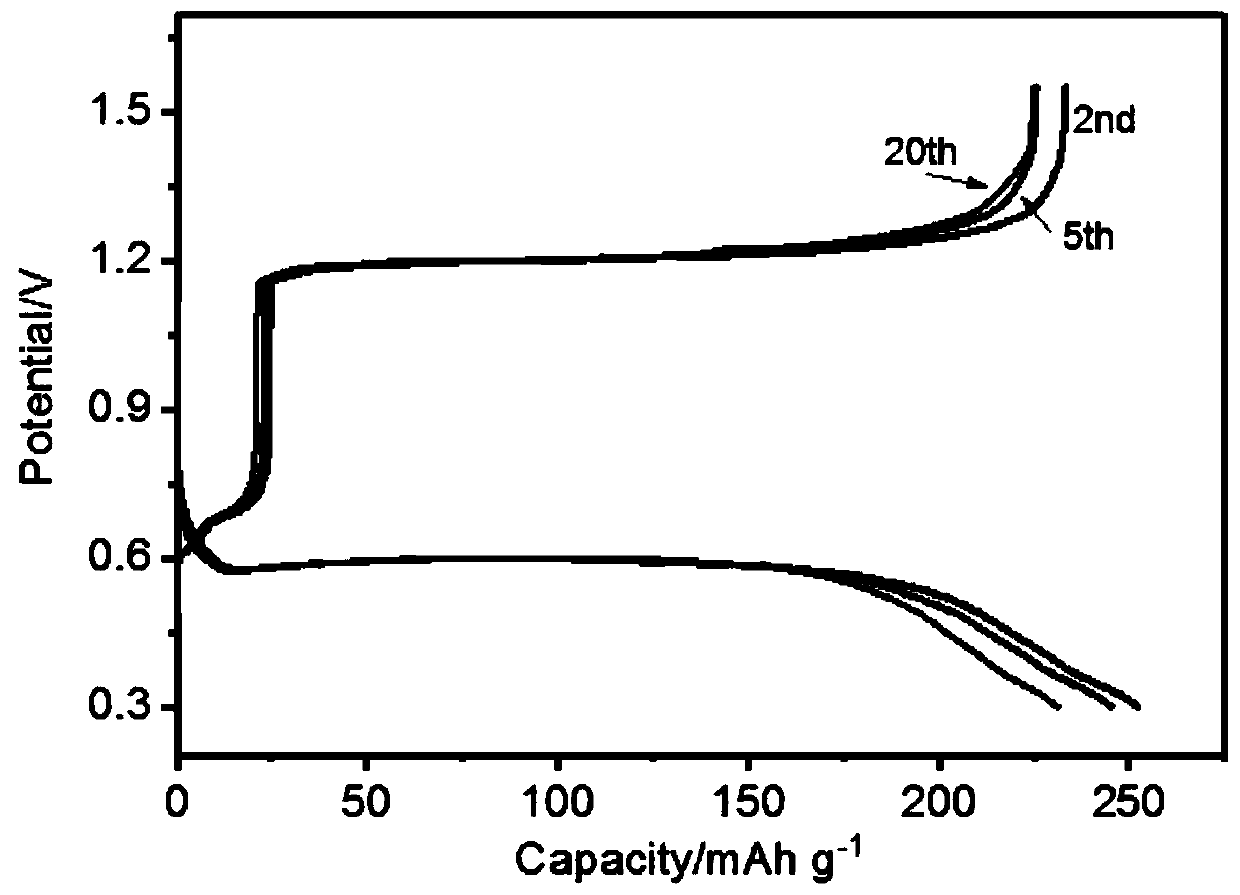

[0062] Depend on Figure 5 It can be seen that the charging and discharging behavior of the aqueous zinc-tellurium secondary batter...

Embodiment 3

[0065] Electrolyte: 2mol / L aqueous solution of zinc trifluoromethanesulfonate.

[0066] Positive electrode: Use simple tellurium as the tellurium active material, mix the tellurium active material, conductive agent and binder at a mass ratio of 7:2:1, coat the surface of titanium foil, cut it into a certain size, and dry it in vacuum A tellurium positive electrode sheet was prepared. The conductive agent is conductive carbon black; the binder is sodium carboxymethyl cellulose (CMC).

[0067] Negative electrode: Use commercially available zinc powder or zinc alloy powder as the zinc active material, mix the zinc active material, conductive agent, porous carbon material and binder in a mass ratio of 6:2:2:1, and coat it on the stainless steel The surface of the foil is cut into a certain size and dried in a vacuum to obtain a zinc powder negative electrode; the conductive agent is conductive carbon black; the binder is PVDF; the porous carbon material is activated carbon.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com