Rotor for rotary electric machine

A technology for rotating electrical machines and rotors, applied in the field of rotors, which can solve problems such as the deformation of the connecting ribs of the rotor core, and achieve the effect of suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

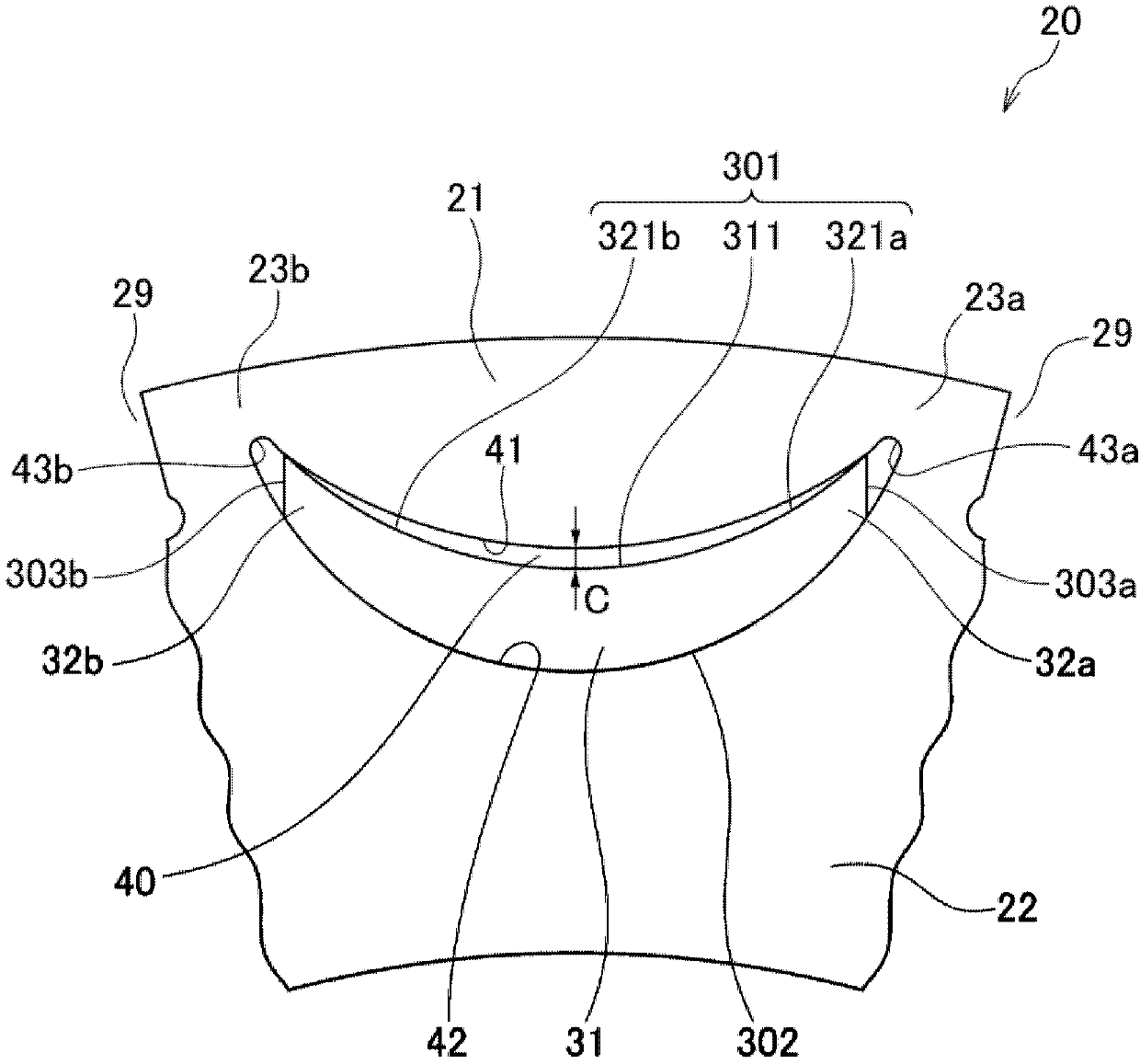

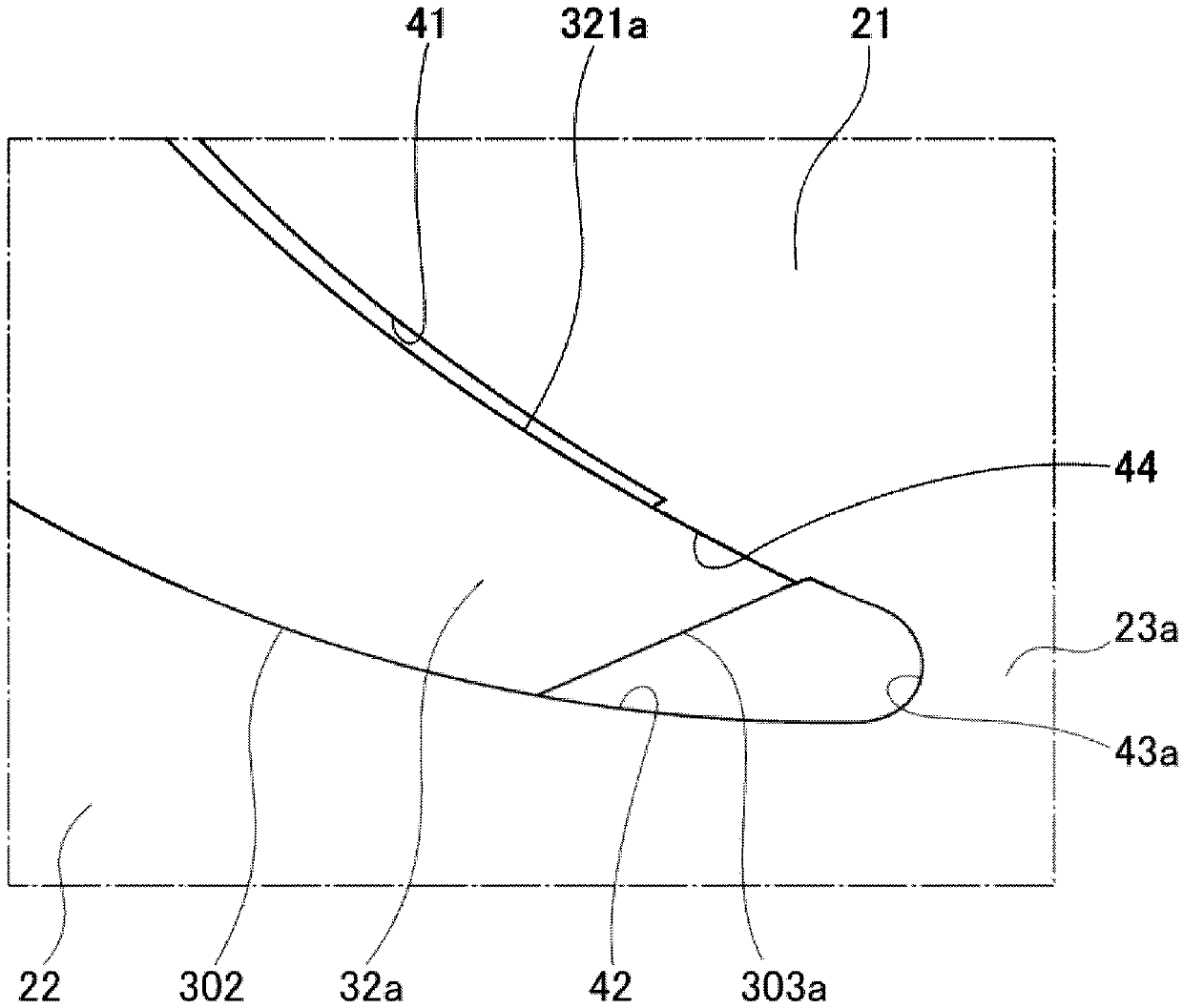

[0059] First, refer to Figure 1 ~ Figure 4 The rotor of the rotating electric machine according to the first embodiment of the present invention will be described.

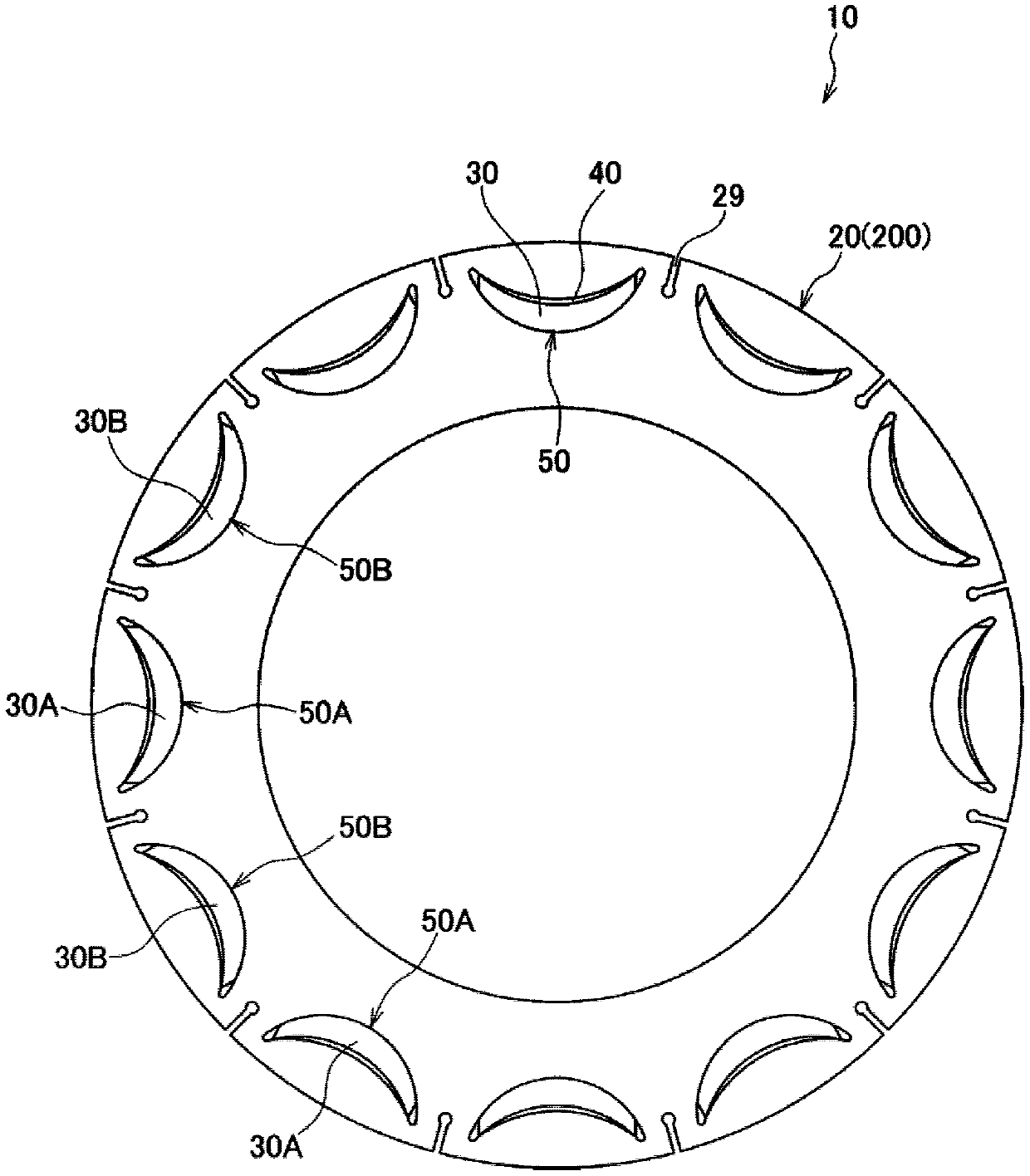

[0060] Such as figure 1 As shown, the rotor 10 of the rotating electric machine according to the first embodiment includes a rotor core 20 attached to the outer peripheral portion of a rotor shaft (not shown), and a plurality of magnetic pole portions 50 formed at predetermined intervals in the circumferential direction inside the rotor core 20 , and the rotor 10 of the rotating electrical machine is disposed on the inner peripheral side of a stator (not shown).

[0061] The rotor core 20 is formed by stacking a plurality of annular electromagnetic steel sheets of substantially the same shape, for example, silicon steel sheets 200 in the axial direction, and has a plurality of magnet insertion holes 40 formed at predetermined intervals in the circumferential direction. In addition, a groove portion 29 is recess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com