Industrial equipment remote data acquisition and processing method and transmission method

A processing method and data acquisition technology, applied in the field of communication, can solve problems such as inability to extract useful information, transmission congestion, and large amount of collected data, and achieve the effects of high data collection and transmission mode, reduced operating pressure, and high collection frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

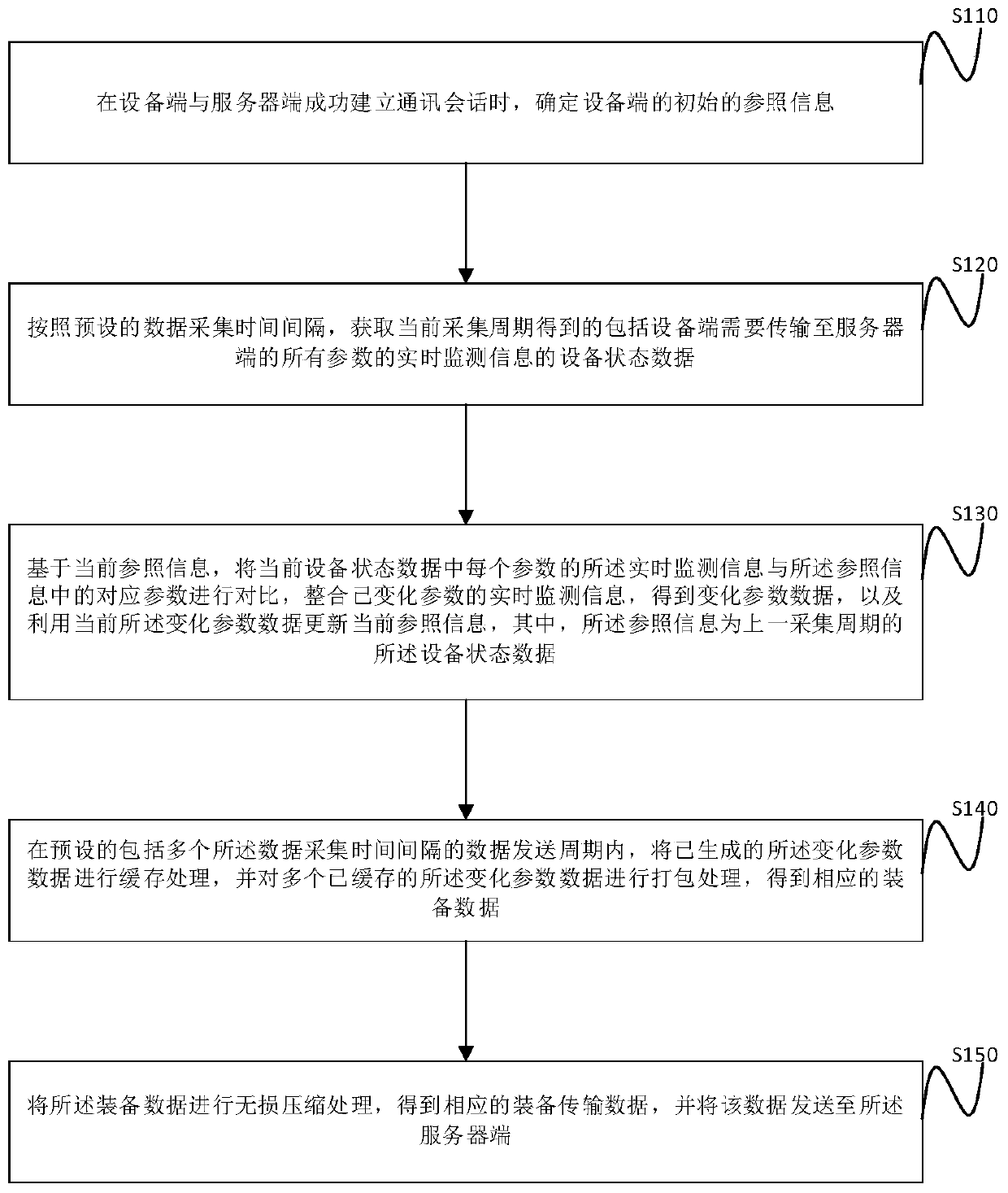

[0040] figure 1 It is a step diagram of the acquisition and processing method in the method for transmitting remote data of industrial equipment according to the embodiment of the present application. figure 2 It is a specific flow chart of the equipment end device 100 used in the collection and processing method in the transmission method of industrial equipment remote data according to the embodiment of the present application. Combine below figure 1 and figure 2 A collection and processing method for transmitting remote data of industrial equipment proposed by the present invention is described.

[0041] In the actual application process, in order to ensure the security of the monitoring data of industrial equipment, the equipment terminal 100 corresponding to the industrial equipment set at different locations needs to establish the connection between the equipment terminal 100 and the server by logging in to the server through a user with a legal identity. The commun...

Embodiment 2

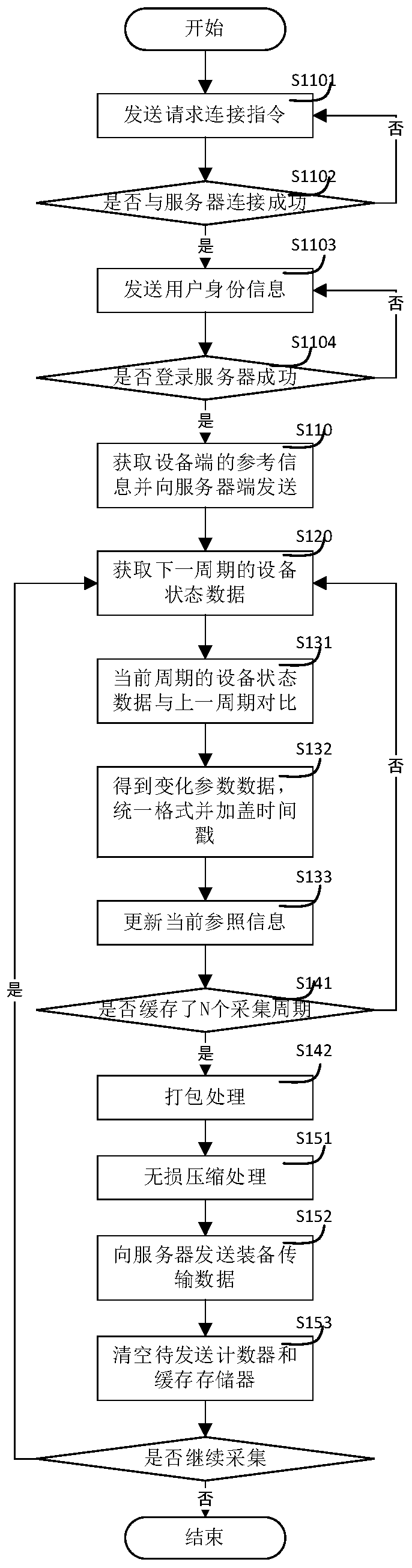

[0059] In the embodiment of the present invention, in order to reduce the data processing and storage pressure of the server end 200, the frequency of data collection of the device end 100 can be adjusted according to the current working state of the current device end 100 or the load condition of the server end 200, so as to The frequency of data sending is reduced to reduce the pressure on the server 200 .

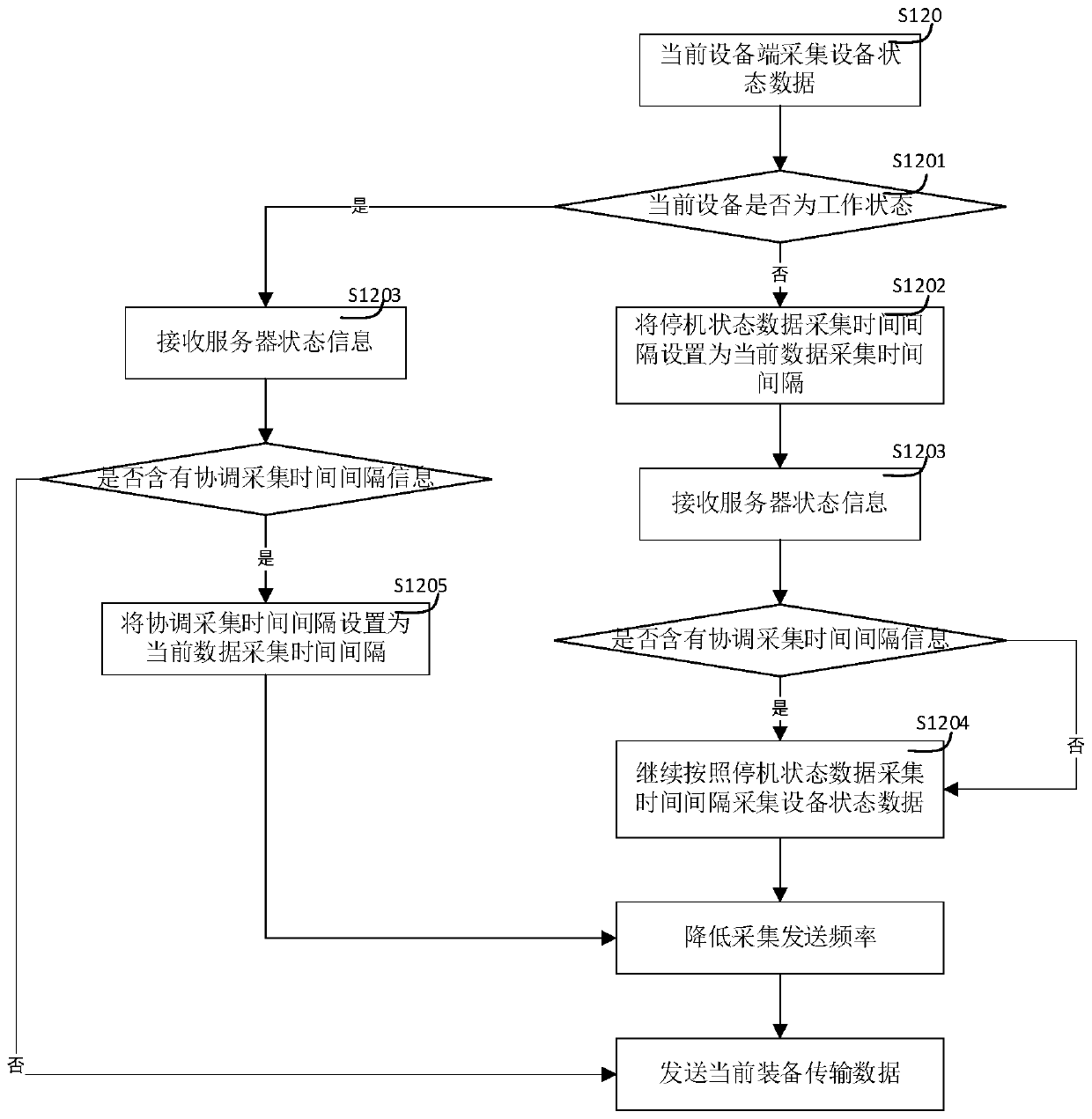

[0060] image 3 It is a flow chart of the acquisition frequency adjustment strategy of the acquisition and processing method used in the remote data transmission method of industrial equipment according to the embodiment of the present application. Such as image 3 As shown, in step S1201, the current equipment terminal 100 obtains and detects the equipment status data collected in real time, and judges the current working status of the current industrial equipment, that is, judges whether the current equipment is in the working status. Specifically, by detecting the s...

Embodiment 3

[0069] Figure 4 It is a step diagram of a receiving and processing method in a method for transmitting remote data of industrial equipment according to an embodiment of the present application. Figure 5 It is a specific flowchart of the server-side device 200 used in the receiving and processing method in the method for transmitting remote data of industrial equipment according to the embodiment of the present application. Combine below Figure 4 and Figure 5 A receiving and processing method for transmitting remote data of industrial equipment proposed by the present invention is described. Wherein, the receiving and processing method corresponds to the collection and processing method in Embodiment 1 and Embodiment 2.

[0070] Such as Figure 4 and Figure 5 As shown, in step S210, when the device end 100 and the server end 200 successfully establish a communication session, the server end 200 receives the equipment transmission data obtained through the above collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com