Needle door type mousetrap cage

A mouse trap and needle door technology, which is applied in the field of mouse traps, can solve the problems of no standardization and large-scale industrial production products, etc., and achieve the effects of easy promotion, safe mouse trapping process, and easy disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

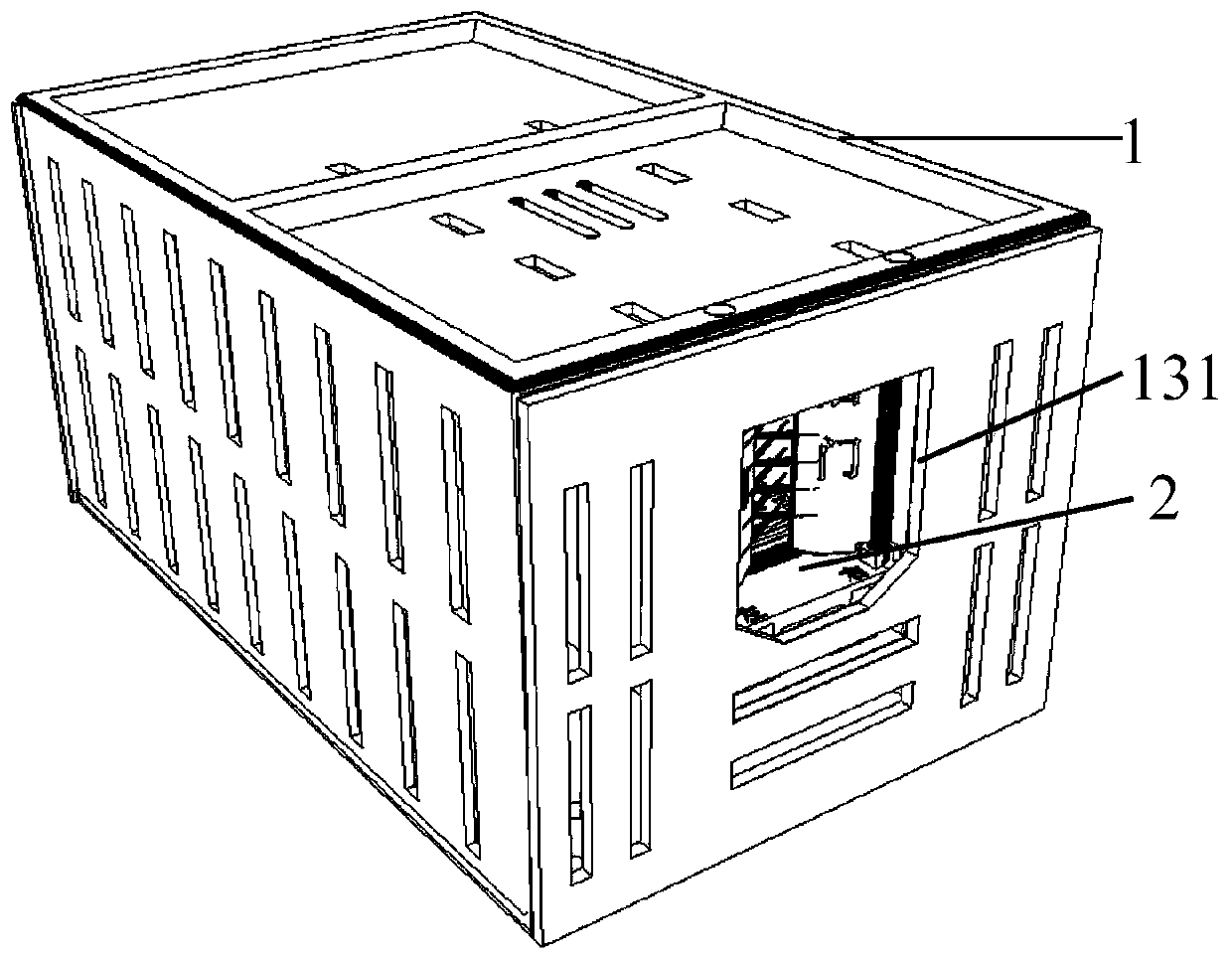

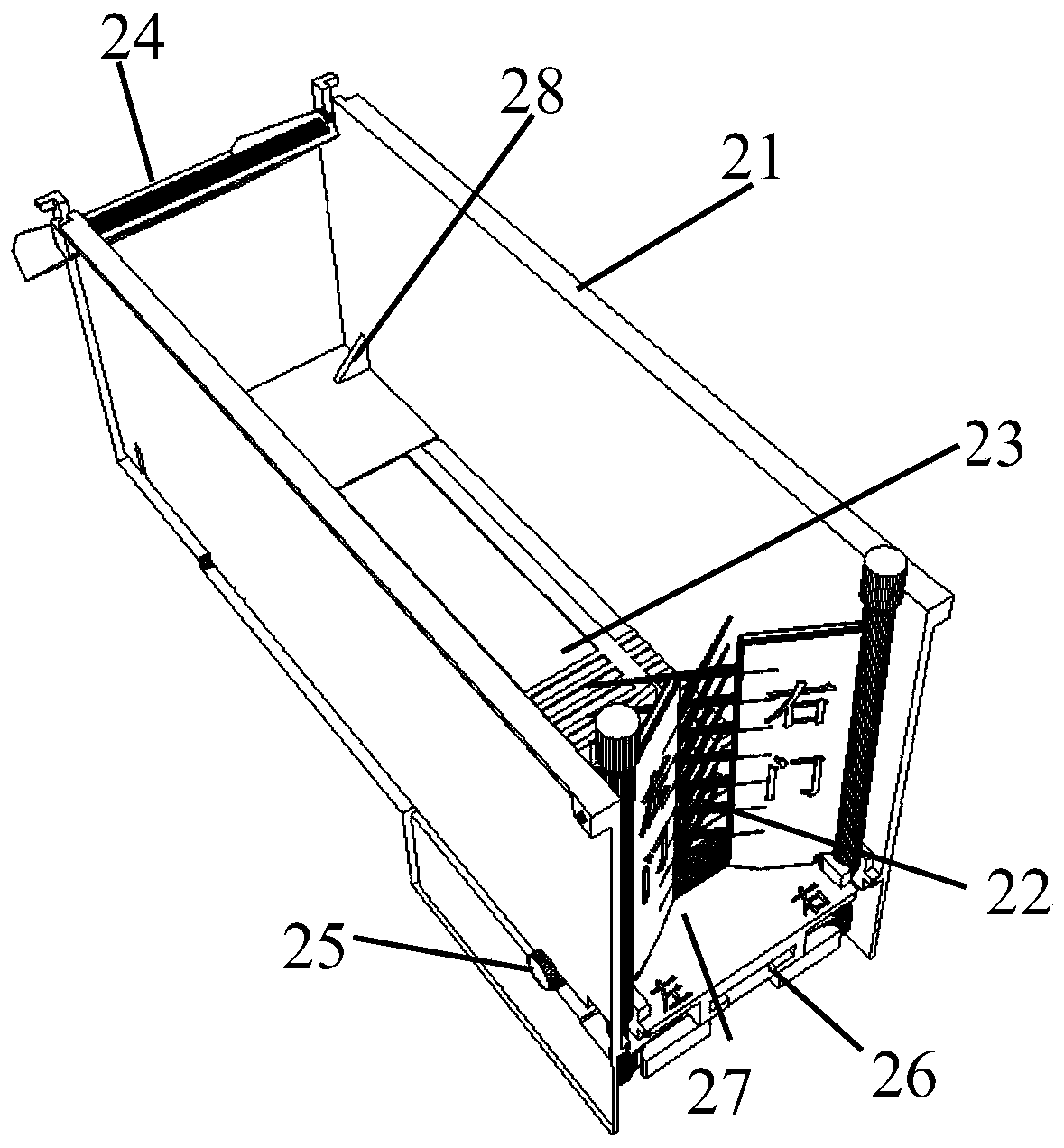

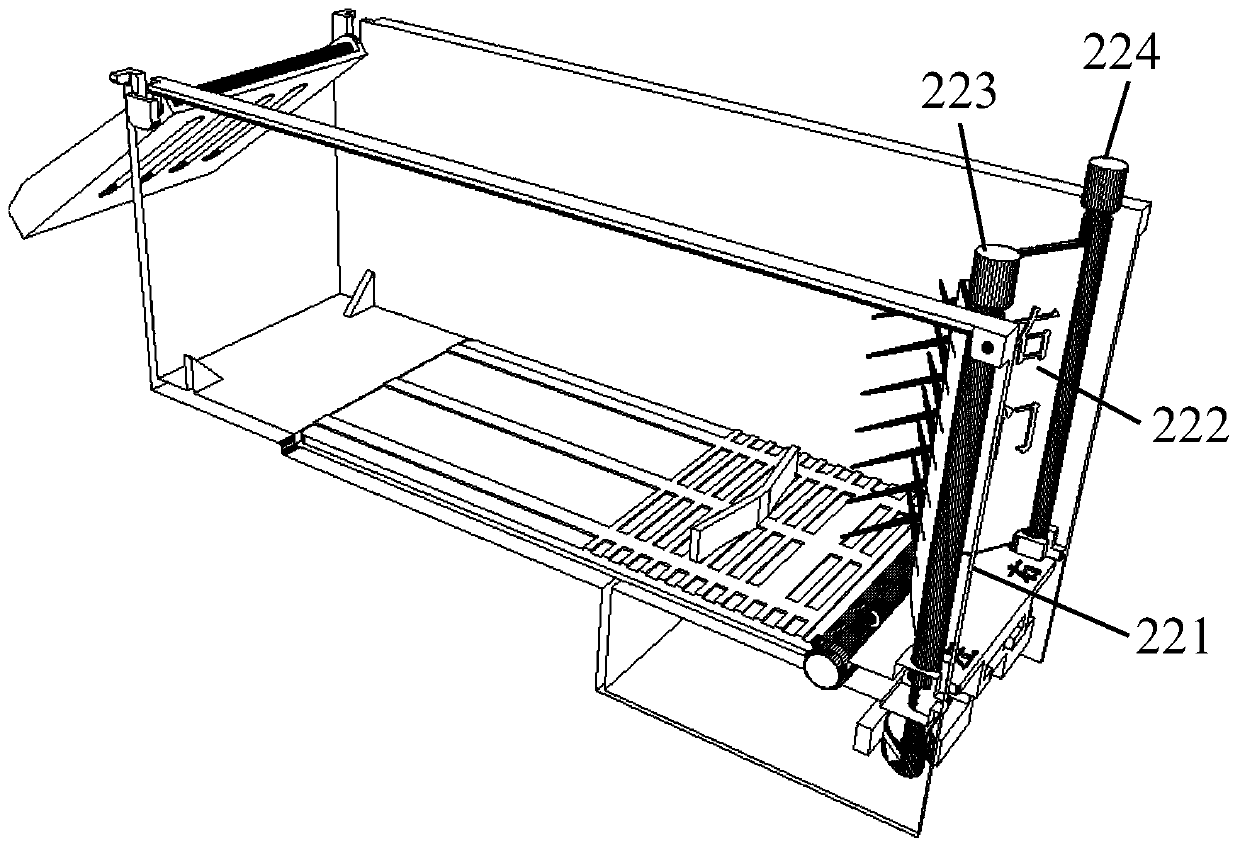

[0030] Please refer to figure 1 , figure 2 , a needle door type mousetrap cage, comprising an outer cage 1 and an inner groove assembly 2 installed on the inner top surface of the outer cage, the inner groove assembly 2 is suspended on the upper top surface inside the outer cage and the inner groove assembly The length is smaller than that of the outer cage, and the inner tank assembly includes an inner tank body 21, a rotating needle door 22, a seesaw 23, and a rear hanging door 24; the rotating needle door 22 is installed at the open front end of the inner tank body, and the outer cage rotates facing The area of the needle door 22 is provided with an opening 11, which is the opening for mice to enter; the seesaw 23 is installed on the front part of the bottom plate of the inner tank body 2 through a torsion spring device 25, and the bottom of the seesaw 23 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com