Sandblasting fire extinguishing device, sandblasting fire extinguishing vehicle and sandblasting trailer

A technology of a fire extinguishing device and a box body, which is applied in the field of emergency rescue, and can solve problems such as easy blockage of the valve port by sand, high vehicle power, and high sand density, so as to improve the efficiency of fire fighting and the safety of rescue, improve efficiency and Safety, the effect of long spraying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

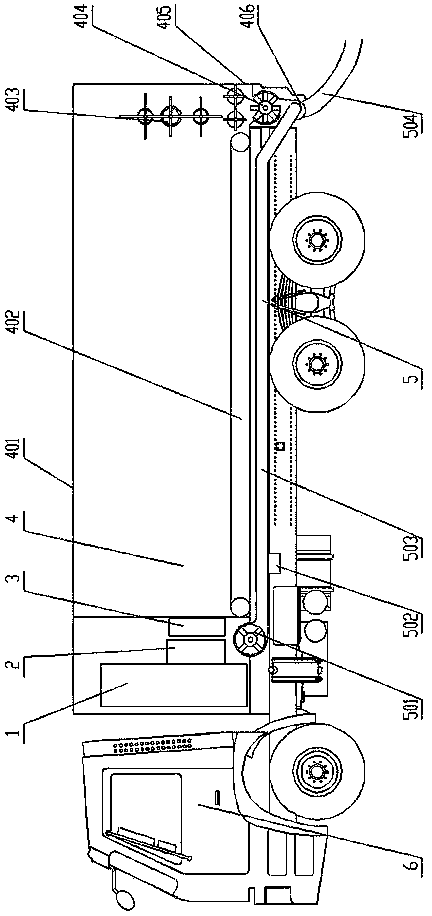

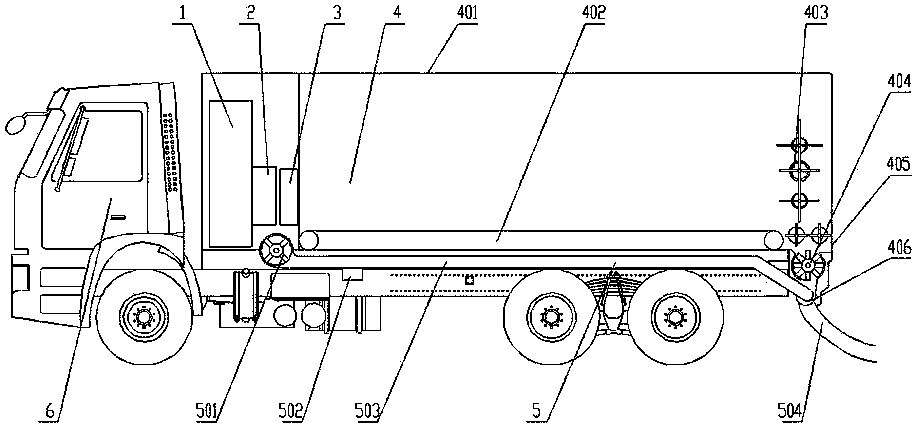

[0035] combine figure 1 As shown, the sandblasting fire extinguishing device of the present invention includes a cargo compartment assembly 4 and a sprinkler system 5 .

[0036] The cargo compartment assembly 4 includes a compartment body 401 , a conveyor belt 402 , a material guide mechanism 403 , a rotary unloader 404 , a rear compartment door 405 , and a mixing chamber 406 . It is mainly used to store materials and complete material transportation and feeding.

[0037] The spraying system 5 includes a fan 501 , a first pipeline 503 , a pressure control component 502 and a second pipeline 504 . It mainly provides pressure gas, which can drive the material to be sprayed out.

[0038] The box body 401 is used for storing materials and installing functional components. The top of the box body 401 can be opened to facilitate loading of materials. The conveyor belt 402 is installed at the bottom of the box body 401, extends from the front end of the box body 401 to the top of...

Embodiment 2

[0049] On the basis of the sandblasting fire extinguishing device of embodiment 1, in the present embodiment, as figure 1 As shown, the sand blasting fire extinguishing device is carried by the chassis system 6 to form a sand blasting fire extinguishing train.

[0050] The cargo box assembly 4 is installed on the vehicle frame of the chassis system 6 through the transition vehicle frame. The chassis system 6 carries the sand blasting fire extinguishing device and drives the whole vehicle. The high-speed chassis with tires can be used to facilitate the vehicle to quickly arrive at the rescue site and carry out fire fighting work.

[0051] The power system 1, the hydraulic system 2 and the control system 3 are all correspondingly integrated to provide power, hydraulic pressure and control functions for the sandblasting truck.

[0052] Others are the same as in Example 1.

Embodiment 3

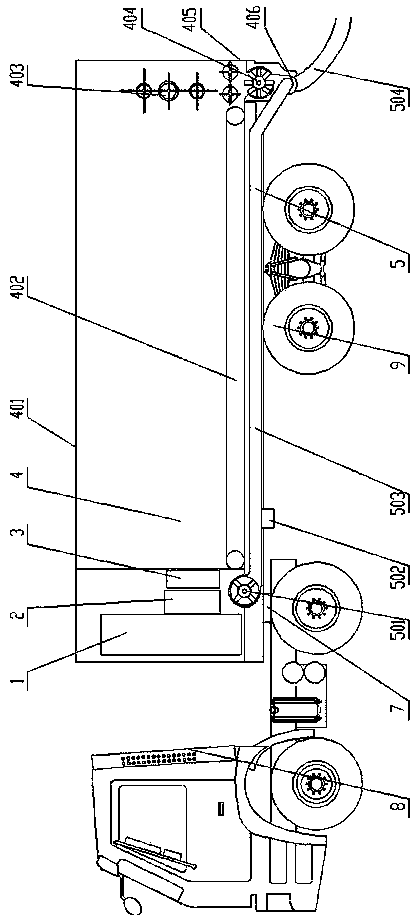

[0054] On the basis of the sandblasting fire extinguishing device of embodiment 1, in the present embodiment, as figure 2 Shown, adopt trailer 9 to carry sandblasting fire extinguishing device to constitute sandblasting trailer.

[0055] In this embodiment, a traction seat 7 is also provided to connect with the tractor 8. In other embodiments, the trailer 9 can be mounted on various main traction vehicles, which can realize the requirement of multiple trailers for one vehicle, and improve the utilization rate of the vehicle.

[0056] The power system 1, the hydraulic system 2 and the control system 3 are all correspondingly integrated to provide power, hydraulic pressure and control functions for the sandblasting truck.

[0057] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com