Single-drawing-strip-belt paint glazing line and working method thereof

A paint line and strip technology, applied in the mechanical field, can solve the problems of long paint drying cycle, cumbersome operation, low efficiency, etc., and achieve the effects of shortening the painting cycle, simplifying manual operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

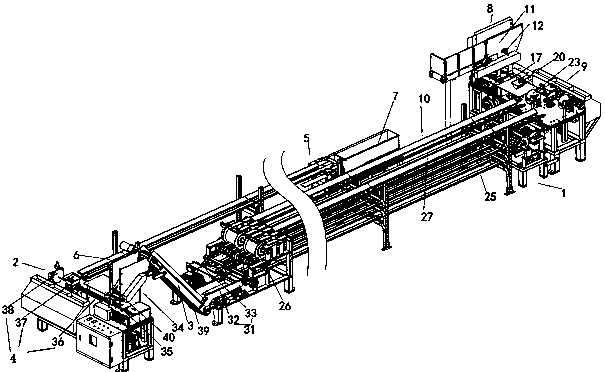

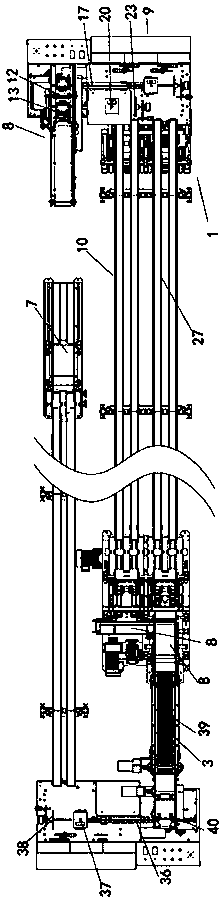

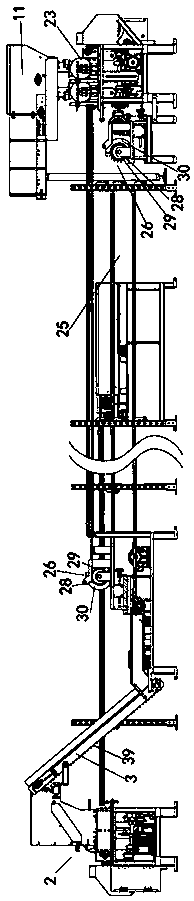

[0025] Such as Figure 1~7 As shown, a single-drawing strip glazing paint line includes a blanking conveying mechanism, and the tail end of the blanking conveying mechanism is connected with a glazing mechanism, and the glazing mechanism includes a lifting conveyor chain, through The lifting conveyor chain transports the pencils to the varnish mechanism, and after being painted by the varnish mechanism, it falls freely into the collecting mechanism, and then horizontally transports them to the collecting hopper through the conveyor belt of the collecting mechanism.

[0026] In the embodiment of the present invention, the blanking conveying mechanism includes a double-branch blanking mechanism, a conveying strip painting mechanism and a multi-layer drying mechan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap