Roller type jujube sorting machine

A sorter, drum-type technology, applied in solid separation, sieves, grids, etc., can solve the problems of low sorting efficiency, difficulty in clearing blockages, and jujube clogging filter holes, etc., and achieves high screening accuracy, Easy to promote and use, good screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

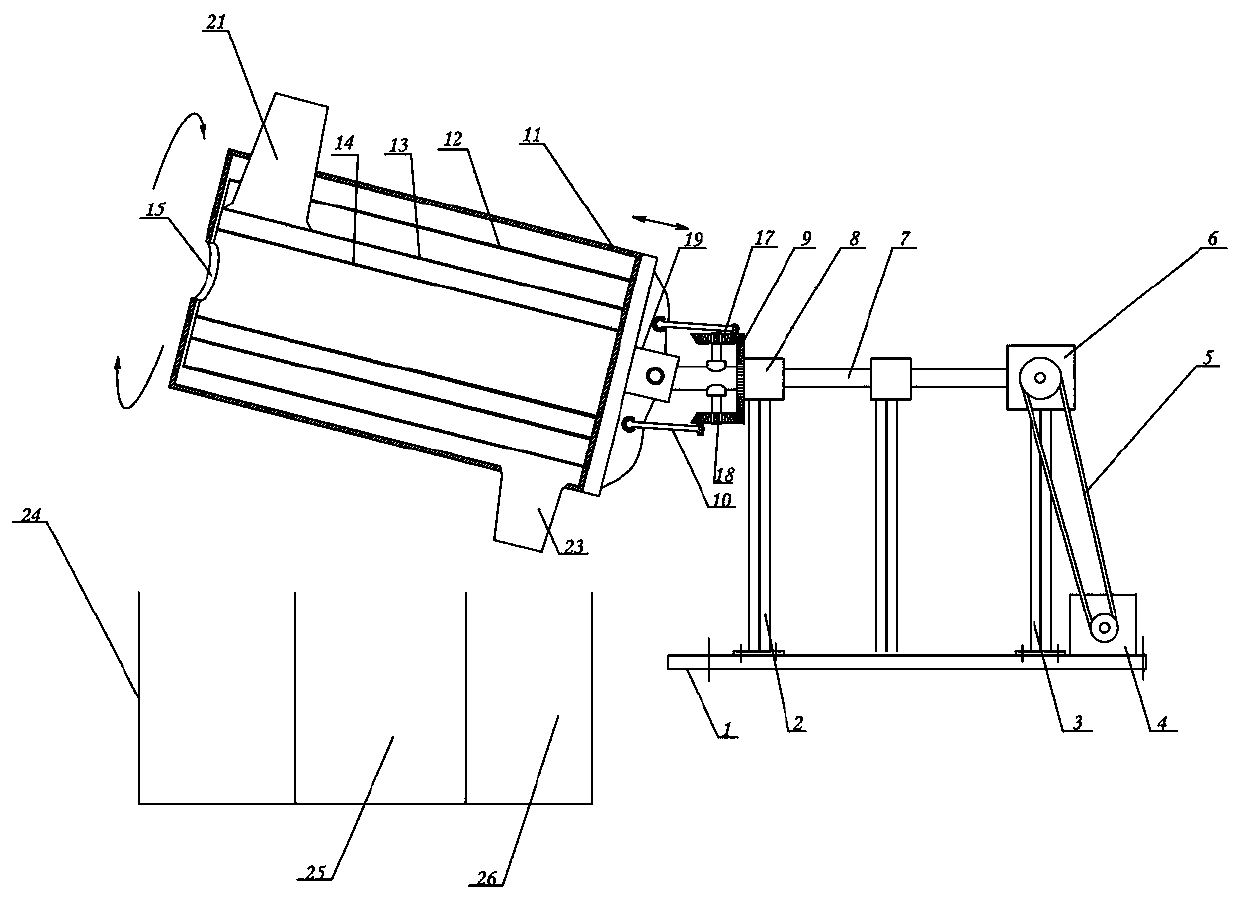

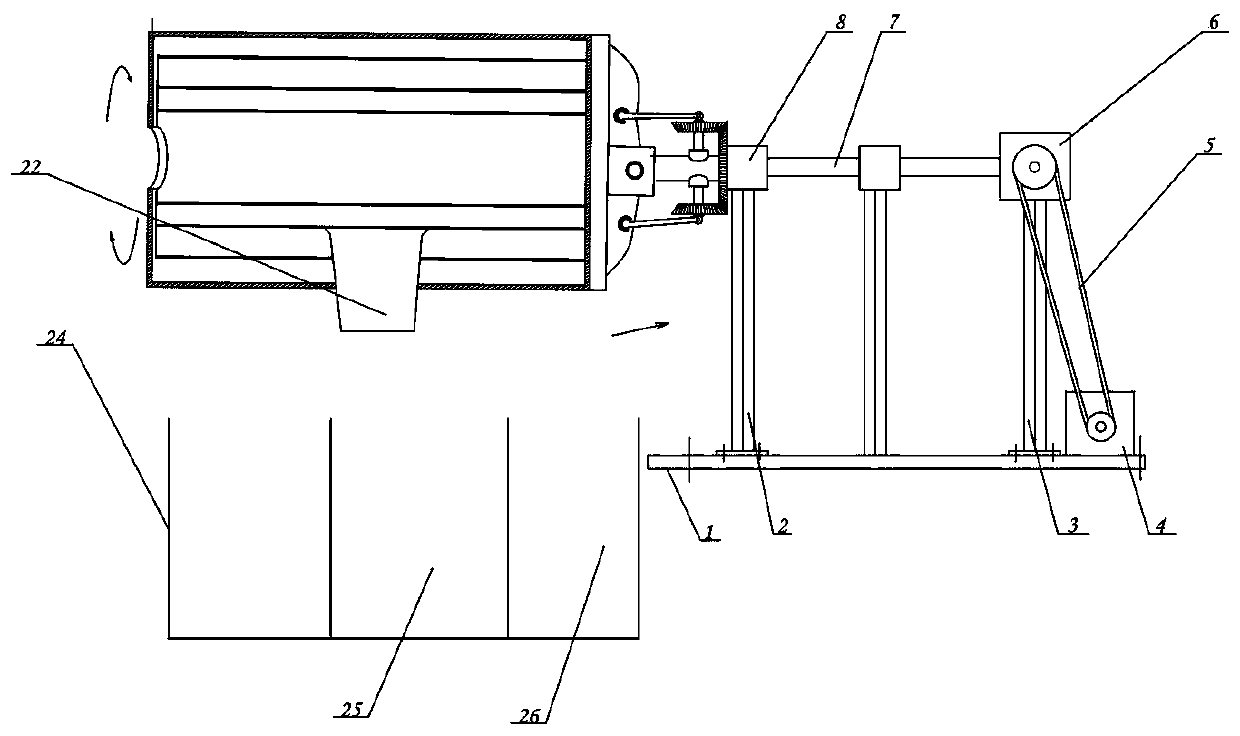

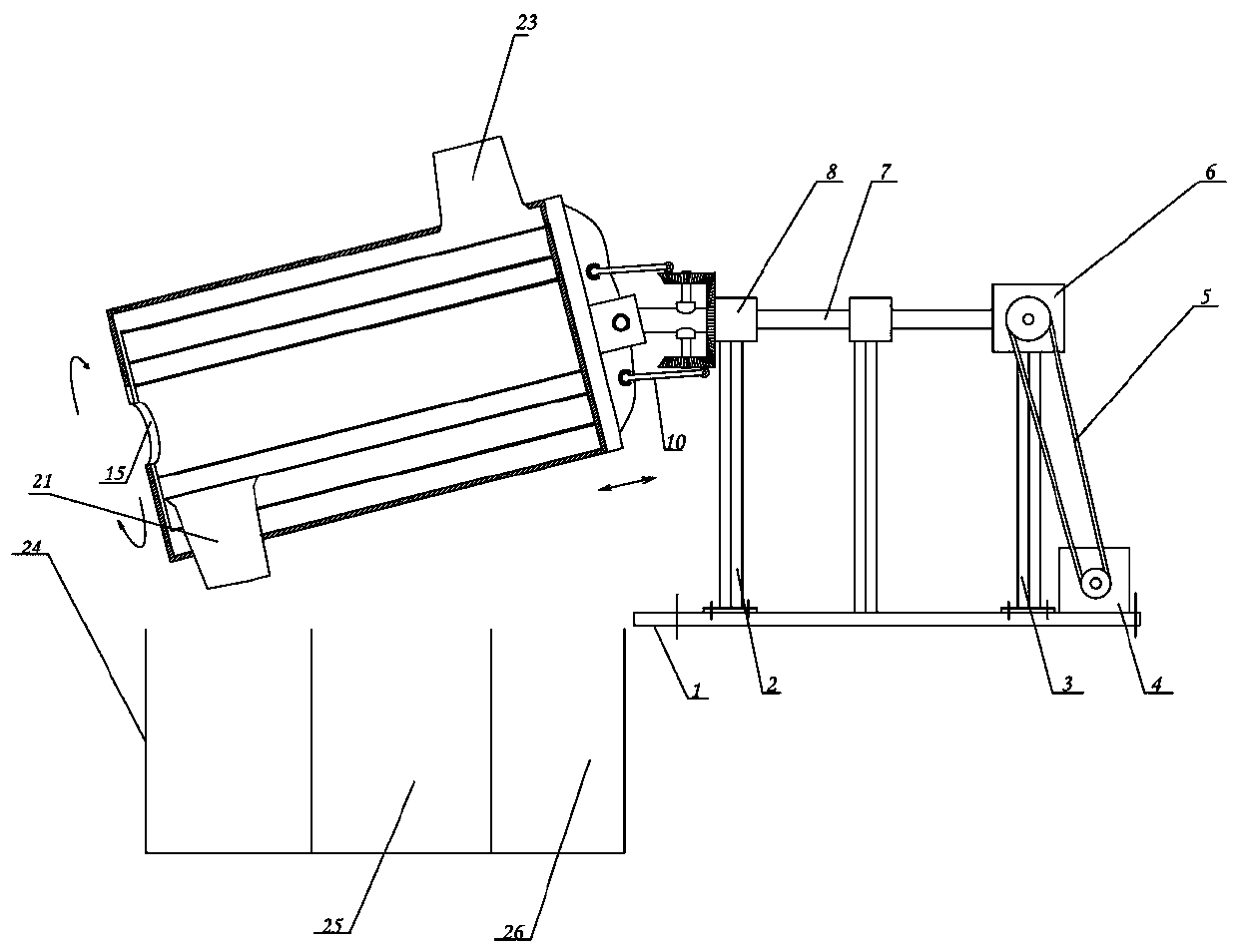

[0024] Embodiment 1: The present invention provides a drum type jujube sorting machine, which aims to solve the problems of low sorting efficiency in existing equipment, and the jujubes are prone to clogging the filter holes and difficult to clean up the blockage during the sorting process. From Figure 1-3 It can be seen that the drum-type jujube sorting machine includes a horizontally arranged base 1. The front and rear ends of the base 1 are respectively fixedly installed with a front bracket 2 and a rear bracket 3 by bolts, and the upper end of the front bracket 2 is fixedly installed with a tubular sleeve 8 , The bearing is installed in the tubular sleeve 8, the horizontal shaft 7 is sleeved in the shaft hole of the bearing, the upper end of the rear bracket 3 is fixedly installed with the gearbox 6, the input shaft of the gearbox 6 and the driving mechanism 4 are connected by the transmission belt 5, the gearbox 6 The output shaft is connected to the rear end of the horiz...

Embodiment 2

[0029] Embodiment 2, this embodiment is basically the same as embodiment 1, the difference is that the first mesh drum 14, the second mesh drum 13, and the first mesh drum, which are concentric with the drum device 11, are arranged inside the drum device 11 from the inside to the outside. Three mesh drums 12, the filter holes of the first mesh drum 14, the second mesh drum 13 and the third mesh drum 12 are sequentially reduced, and a first discharge pipe 21 and a second discharge pipe 21 are respectively provided The tube 22 and the third discharge tube 23.

[0030] by Figure 5 It can be seen that the first discharging tube 21, the second discharging tube 22, and the third discharging tube 23 are all in the shape of a funnel, which is convenient for jujube to fall into the discharging tube. The discharging tube 22 and the third discharging tube 23 are respectively arranged on the outside of the first mesh drum 14, the middle of the second mesh drum 13 and the inside of the third...

Embodiment 3

[0032] Embodiment 3: This embodiment is basically the same as Embodiment 1, except that the first mesh drum 14, the second mesh drum 13, and the third mesh drum 12 are clamped in the drum device 11, which is not only convenient The net-shaped drum is cleaned and maintained, and the net-shaped drum with different apertures can be replaced as required, which increases the height of the present invention and has a wide application range and is convenient to use.

[0033] At the same time, in order to ensure the stability of the equipment, a middle bracket is arranged in the middle of the front bracket and the rear bracket. The upper end of the middle bracket is provided with the same tubular bushing as the front bracket. The tubular bushing is fitted with a bearing, and the horizontal shaft is fitted in the shaft hole of the bearing. Inside.

[0034] The invention has a novel and unique structure and a reasonable structure. A common driving device is used to drive the horizontal shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com