Rapid mounting device for punching needles of long rectangular table hydraulic punching machine

An installation device, punching machine technology, applied in the direction of punching tools, metal processing equipment, forming tools, etc., can solve the problems of a large number of bolt removal, reduce equipment work efficiency, large workload, etc., to save installation time, compact structure, The effect of simplifying installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

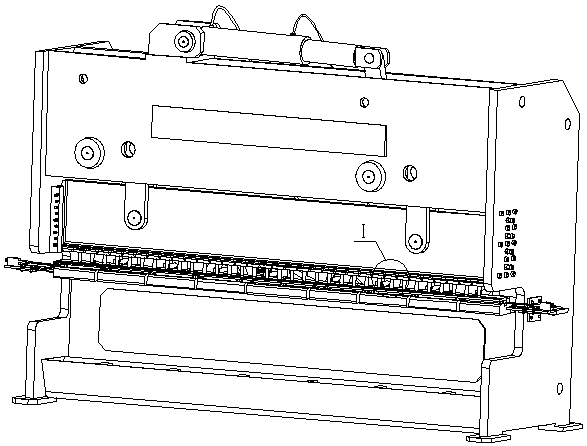

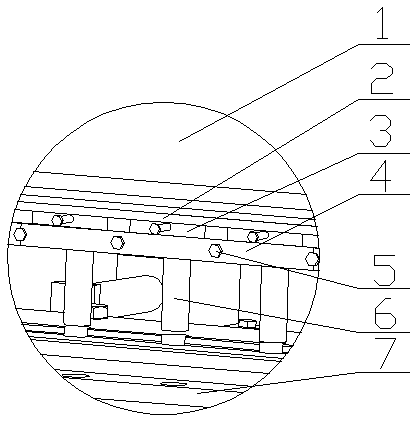

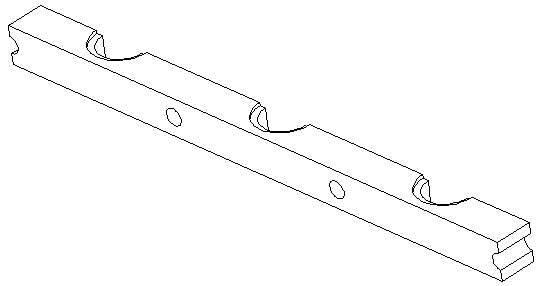

[0015] Such as figure 1 It is a schematic diagram of the structure of the present invention, a quick installation device for punching needles of a long platform hydraulic punching machine. 7. The upper support plate 2 is installed on the tool holder 1, the punch 6 is pressed on the tool holder 1 through the pressure plate 4 and the fastening bolt 5, the plug 3 is placed between the pressure plate 4 and the upper support plate 2, and the lower Mold 7 is installed on the workbench. Said pressing plate 4 is processed with semicircular holes for installing punching pins, and the number of semicircular holes on one pressing plate 4 is 1-8. A plurality of punching pins are arranged as a group and installed at the same time, which greatly simplifies the installation steps and saves installation time. The plug 3 is designed as a semicircle, and a handle is processe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap