Device for welding fixed three-post insulator of GIL

A technology for welding devices and insulators, which is applied to auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient operation of fixtures, difficulty in ensuring the coaxiality of the central conductor and the busbar barrel, and avoid scratches and reduce Effect of low friction and friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

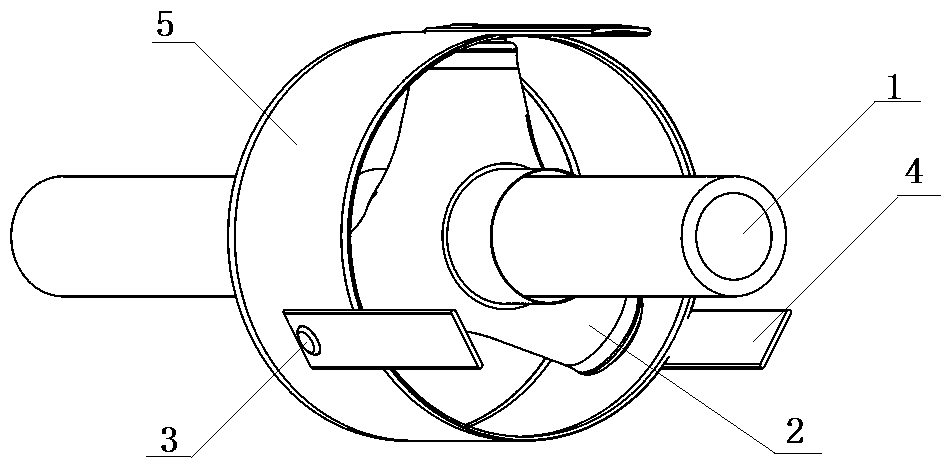

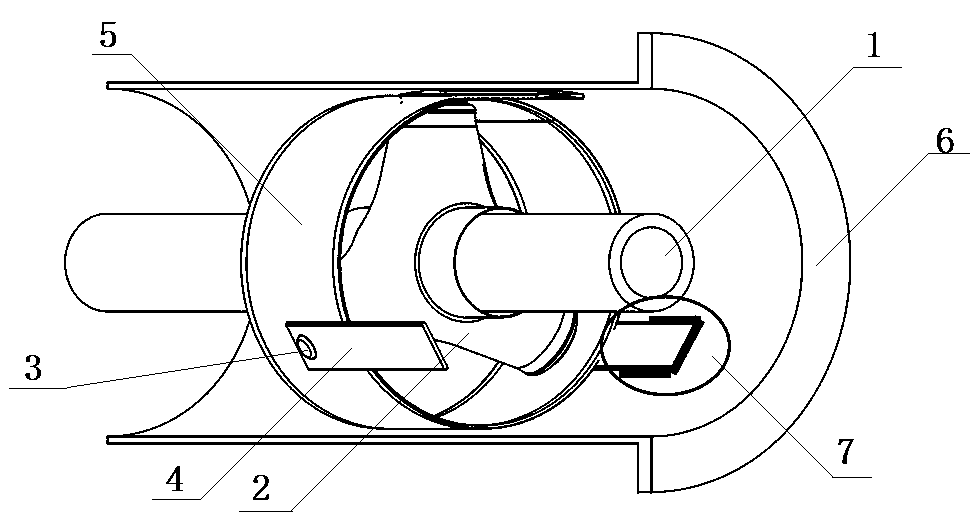

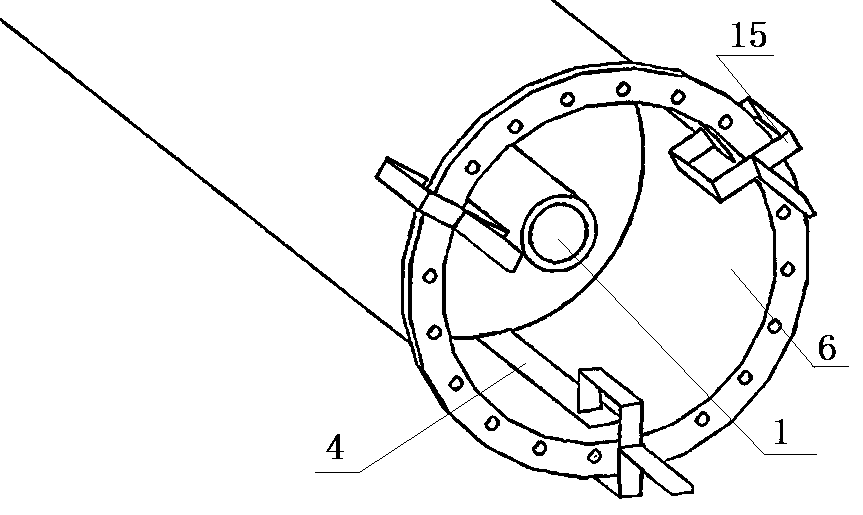

[0027] The specific embodiment of the fixed three-pillar insulator welding device of GIL provided by the present invention:

[0028] Such as Figure 4 with Figure 5 As shown, the fixed three-pillar insulator welding device of GIL includes a fixed seat 14 for coaxially sleeved on the central conductor 1. The fixed seat 14 is an annular seat, and a polytetrafluoroethylene ring 11 is installed on the inner wall of the central hole of the annular seat. , the polytetrafluoroethylene ring 11 has a low coefficient of friction, and when the fixing seat 14 is sheathed on the central conductor 1, it forms a cushion layer for preventing the central conductor 1 from being bumped and scratched.

[0029] The fixed three-pillar insulator welding device of GIL also includes three identical hydraulic cylinders 8 uniformly arranged along the outer circumference of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com