Continuous type station positioning device for multi-station polishing machine

A positioning device and multi-station technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems that the positioning device cannot be accurately sensed, the station disc is misplaced, and the workpiece is easily damaged. Achieve the effect of reliable induction, accurate stop position and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

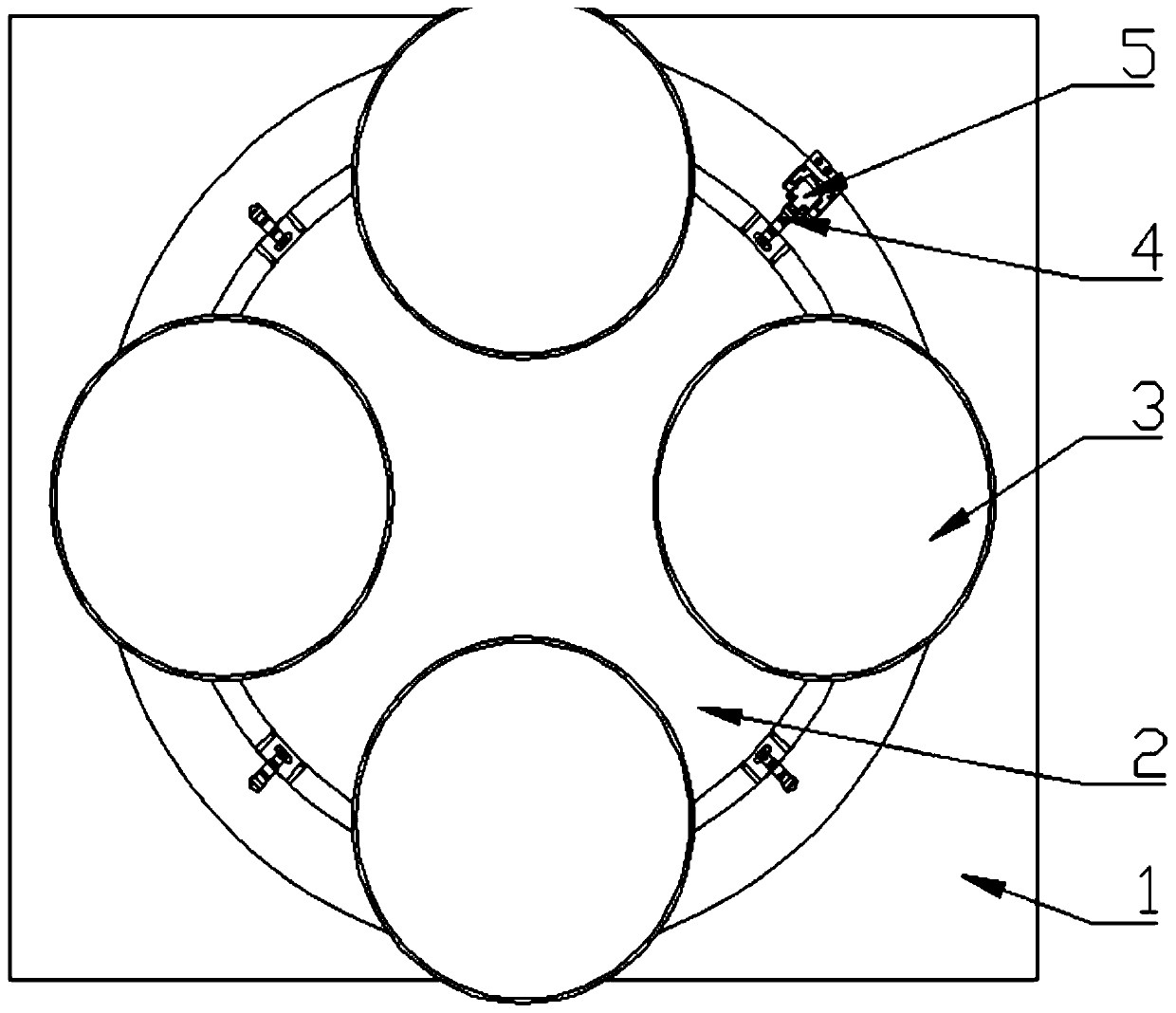

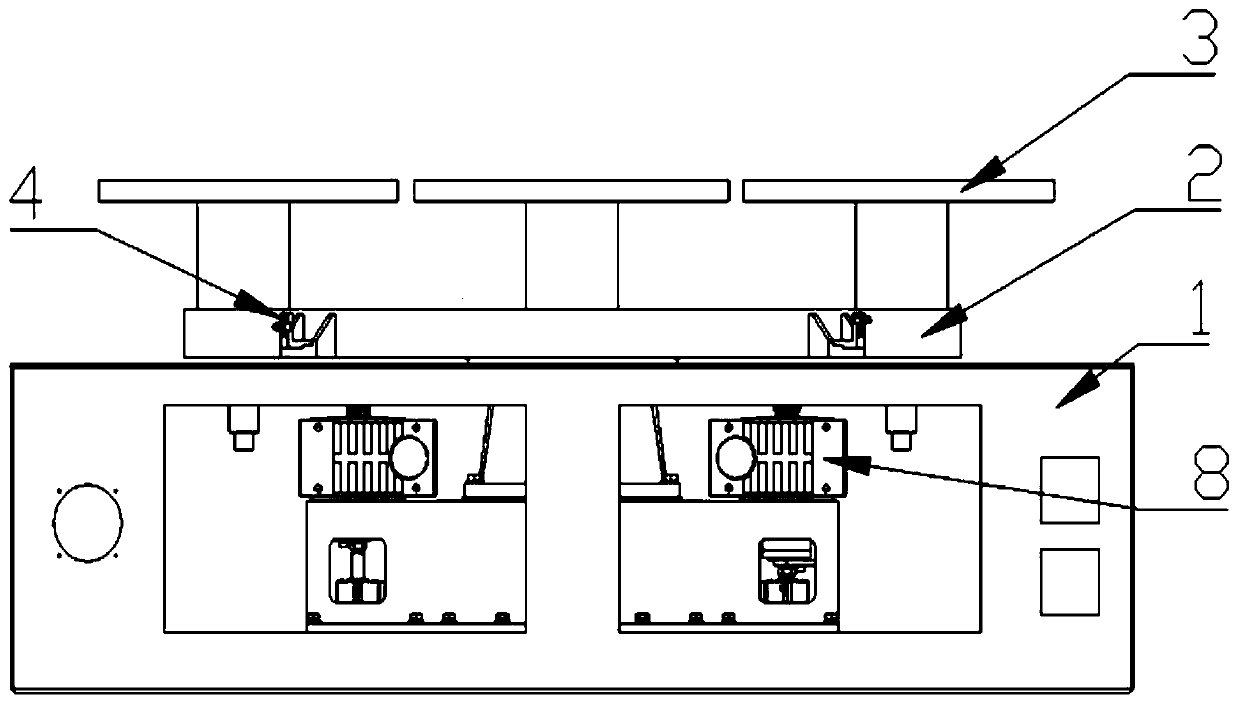

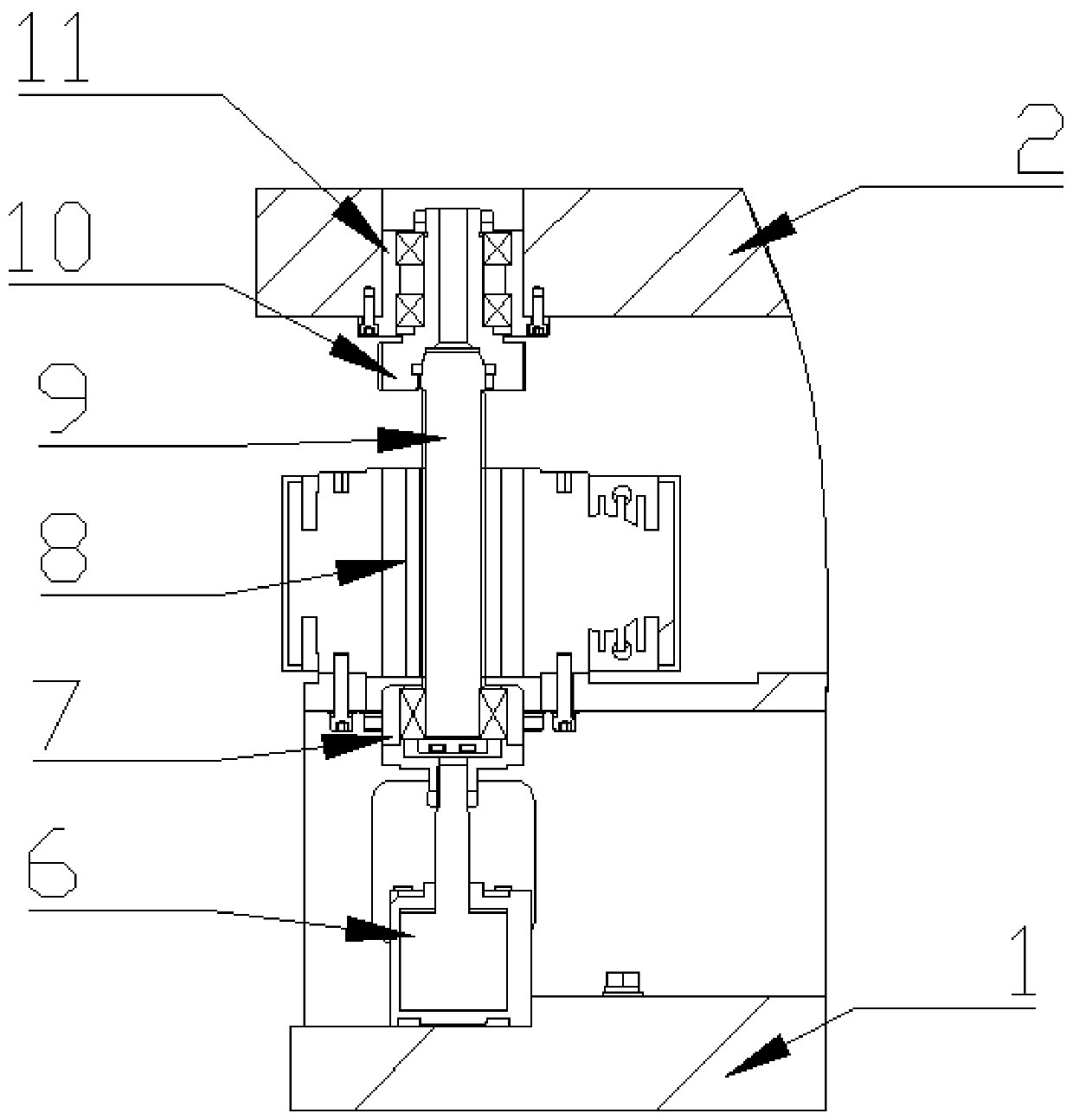

[0020] Referring to the attached drawings, a continuous multi-station polishing machine station positioning device includes a box body 1, a rotating platform 2, a station unit 3, a stroke striker 4, a multi-link stroke switch 5, a positioning cylinder 6, a lifting movable seat 7. Geared motor 8, spline shaft 9, gear shaft 10 and bearing seat 11; the number of the station units 3 are 4, and they are installed on the rotating platform 2 by screws; the multiple travel switch 5 is installed by screws On the box 1, the stroke bumps 4 are four, which are installed at different heights of the rotating platform 2 by screws evenly distributed, and are aligned horizontally with the different sensing points of the multiple travel switch 5. When the stroke bumps 4 When aligning with the multi-link travel switch 5, the corresponding station unit 3 is located directly in front of the machine; the positioning cylinder 6 and the geared motor 8 are both installed on the box 1 by screws, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com