Mechanical arm device and control method of mechanical arm device

A technology of a robot arm and a control method, which is applied in the field of control of a robot arm device and a robot arm device, and can solve problems such as deformation of shelves, change of relative positional relationship, inability to correctly clamp or place wafer carriers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

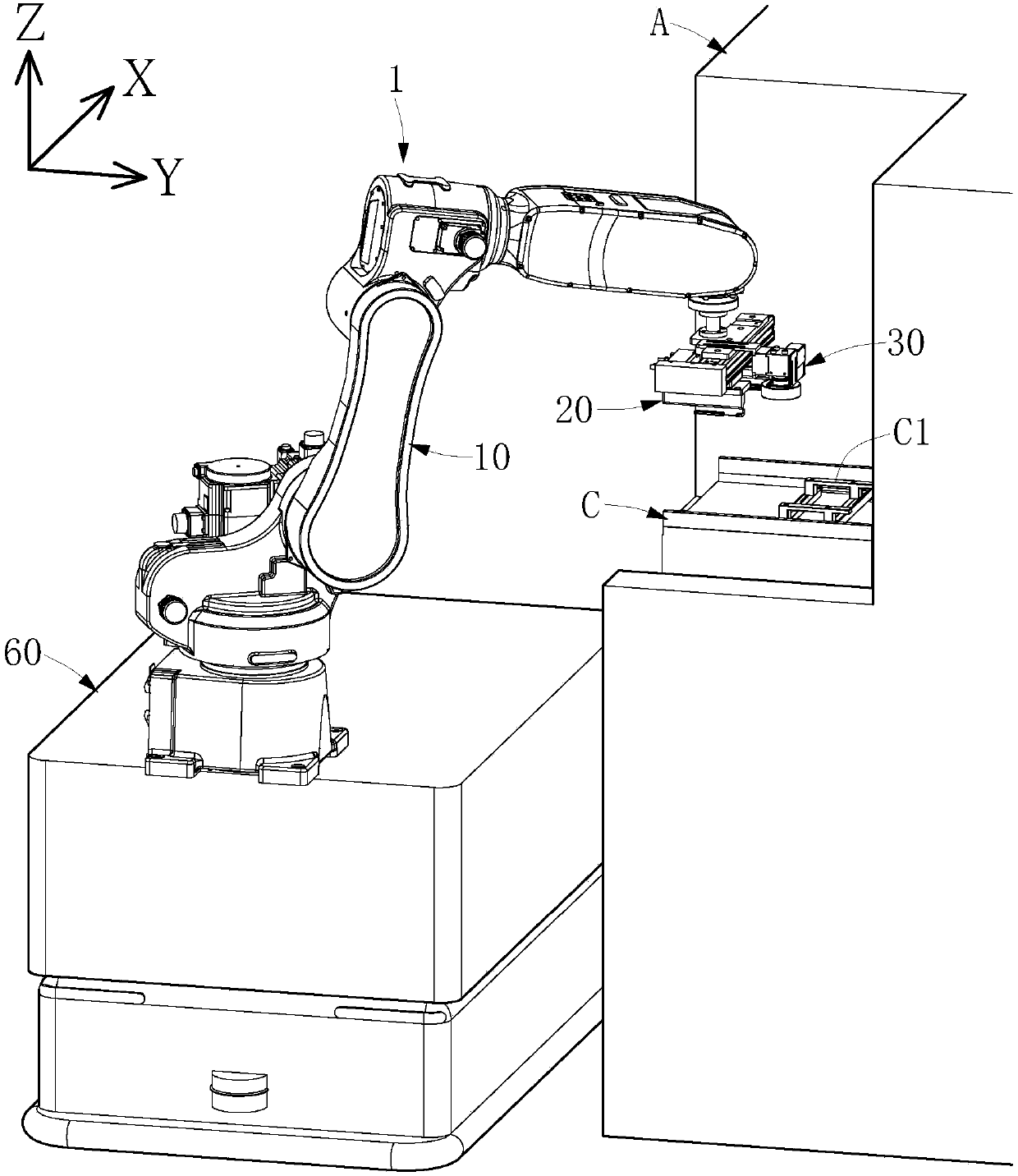

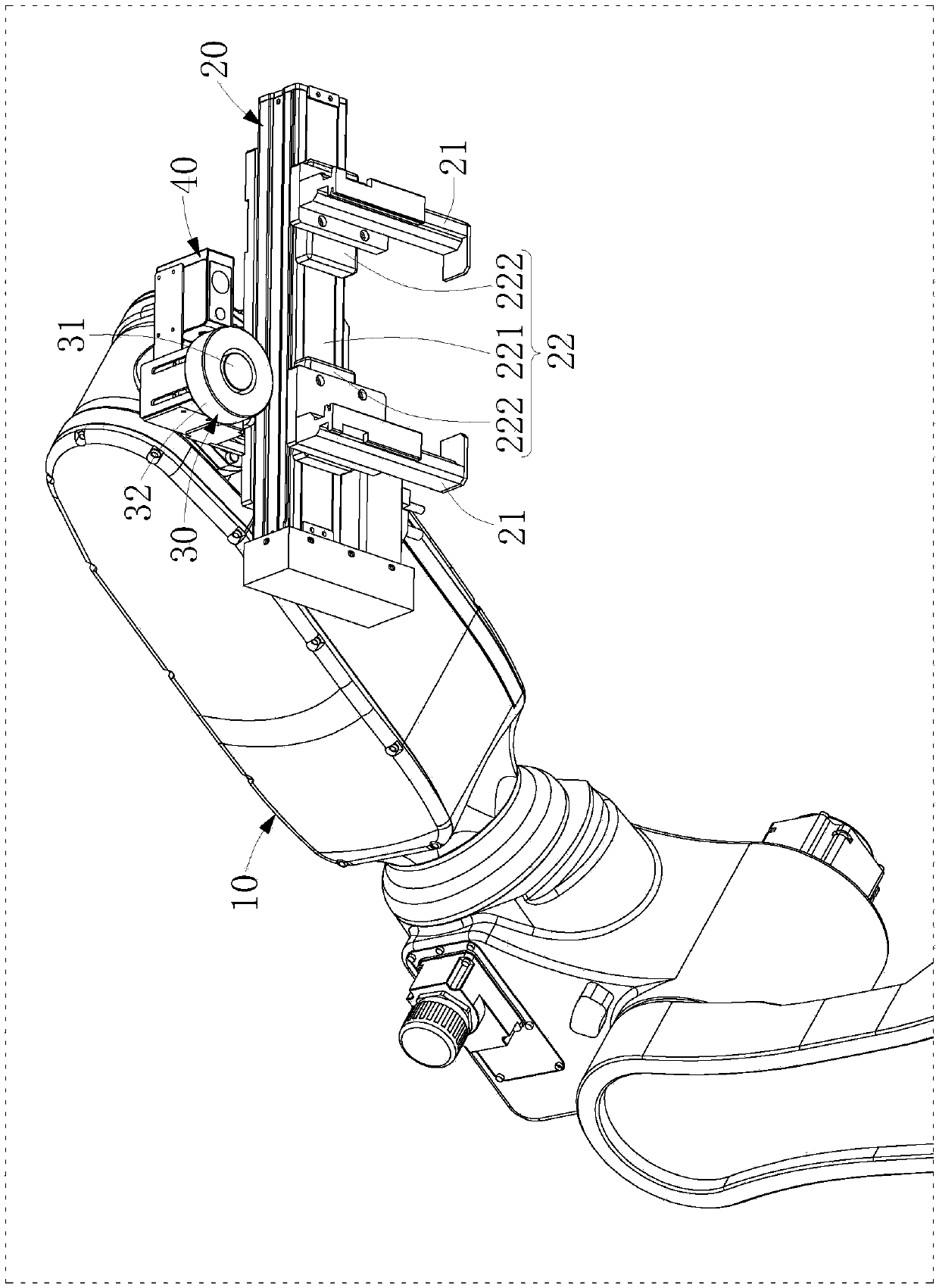

[0029] Please also refer to Figure 1 to Figure 3 and Figure 7 , figure 1 It is a schematic diagram showing that the robot arm device 1 of the present invention intends to clamp a wafer carrier C arranged on a production equipment A; Figure 7 It is a schematic diagram showing that the robotic arm device of the present invention intends to hold a wafer carrier F placed on a shelf B; wherein, figure 1 The morphology of the wafer carrier C shown is the same as Figure 7 The wafer carrier F shown has different shapes, but the robotic arm device of the present invention is not limited to only holding the two types of wafer carriers.

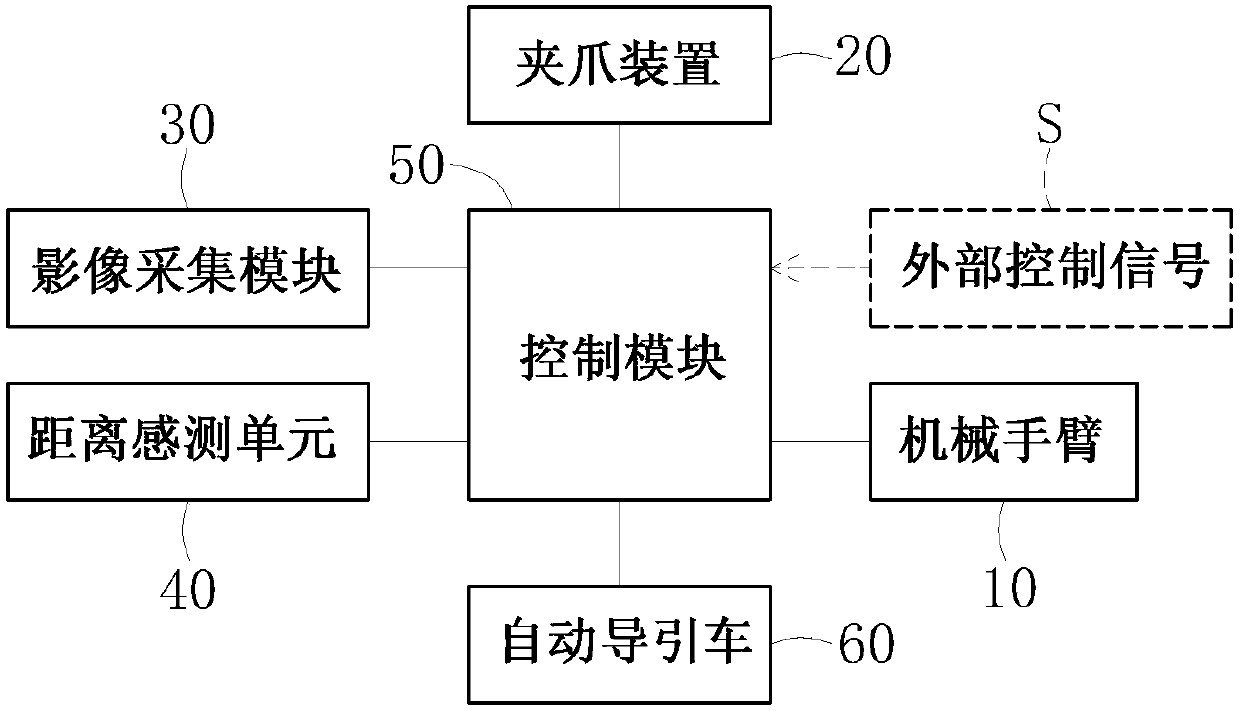

[0030] Such as figure 1 , figure 2 As shown, the robot arm device 1 is used to clamp a wafer carrier C, and the robot arm device 1 includes: a robot arm 10, a gripper device 20, an image acquisition module 30, and at least one distance sensing unit 40 and control module 50 (such as image 3 shown). The robot arm 10 can be movably arranged o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap