Electric cable accessory silicon rubber heating vulcanization mold

A technology for cable accessories and vulcanization molds, applied in the field of cable accessories molds, can solve the problems of slow temperature rise, low production efficiency, long vulcanization time, etc., and achieve the effects of easy management, improved production efficiency and quality, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

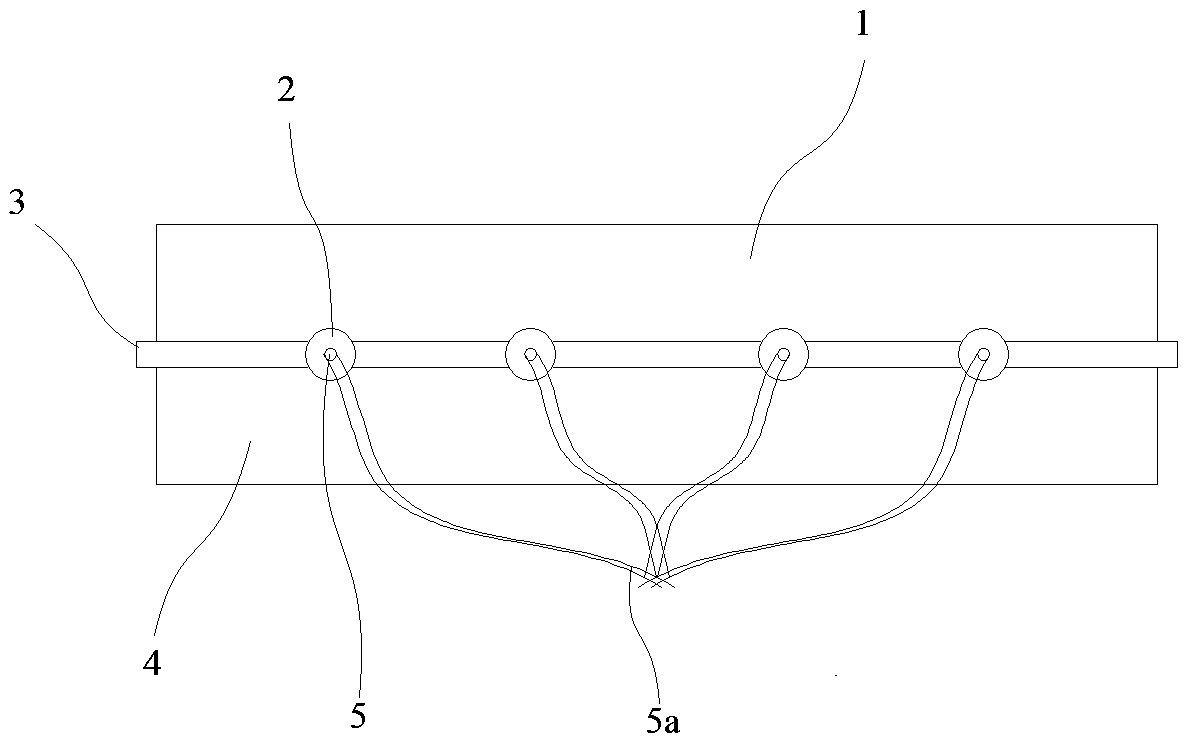

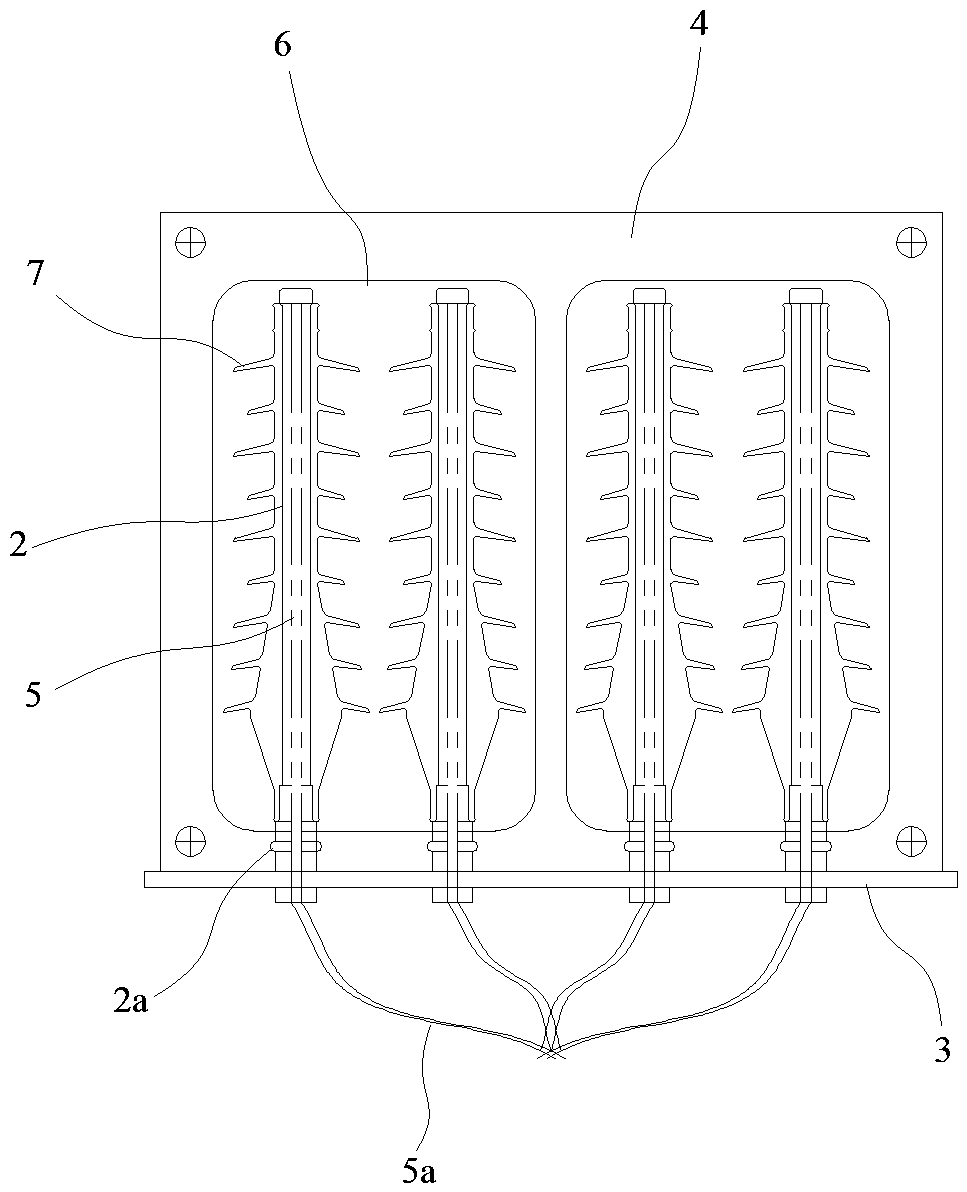

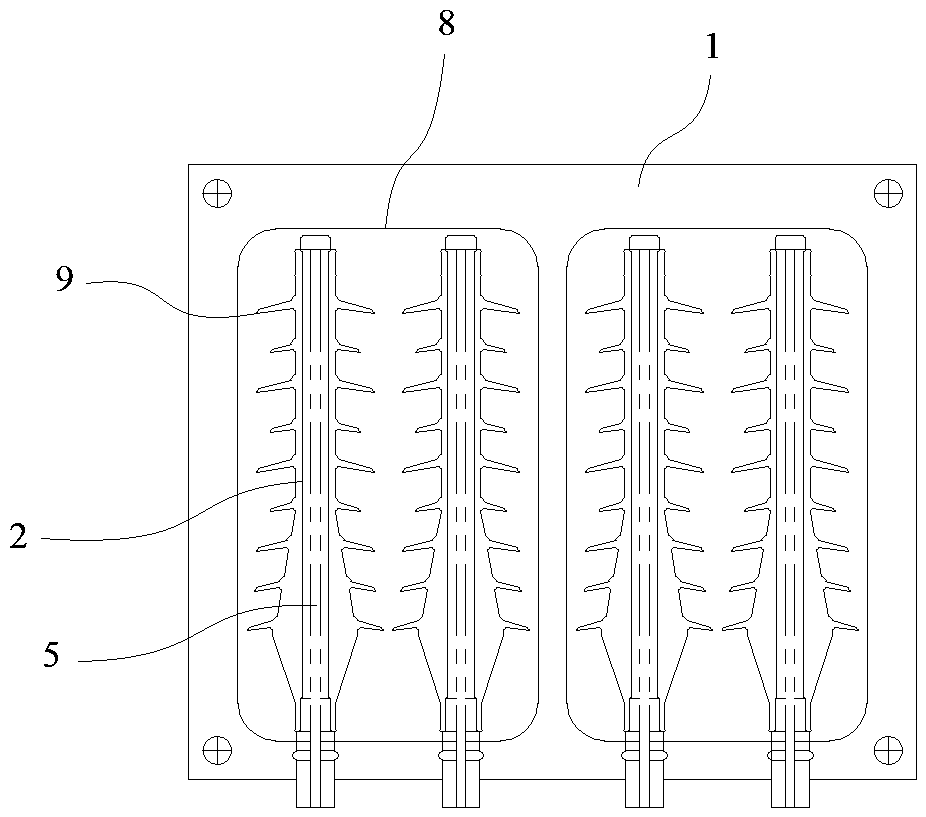

[0021] like figure 1 In the shown embodiment, a silicone rubber heating vulcanization mold for cable accessories includes an upper template 1 and a lower template 4, combined with figure 2 , image 3 As shown, several cavities are arranged between the upper template 1 and the lower template 4 . The upper template 1 is provided with an upper mold core 8, the lower template 4 is provided with a lower mold core 6, the parting surface of the upper mold core 8 is provided with an upper cavity 9, and the parting surface of the lower mold core 6 is provided with a lower cavity 7 , in this embodiment, the upper template is provided with two upper mold cores, the lower template is provided with two lower mold cores corresponding to the upper mold cores, the upper mold core is provided with two upper mold cavities, and the lower mold core is provided with two a lower cavity. When the upper template 1 and the lower template 4 were closed, the upper mold core 8 and the lower mold core...

Embodiment 2

[0026] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the lower template 4 is provided with a horizontally arranged cooling channel 4a, and the lower template 4 is provided with a slideway 4b communicating with the cooling channel 4a, and the slideway 4b is arranged vertically to the cooling channel 4a. A push rod 11 is provided in the slideway 4b, and the push rod 11 can slide up and down along the slideway 4b. The bottom of the push rod 11 is in sliding and sealing cooperation with the inner wall of the slideway 4b, and a sealing ring can be provided to strengthen the sealing effect. The opening at the top of the slideway 4b is located on the upper surface of the lower template 4, and the opening is provided with a spring positioning seat. The slideway 4b is provided with a spring 12. The upper end of the spring 12 is in contact with the spring positioning seat, and the lower end of the spring 12 is in contact with the bottom of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com