Preparation method of lanthanum metaphosphate as high-purity optical glass additive

An optical glass, lanthanum metaphosphate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem that the content of pure metal ion elements of lanthanum metaphosphate cannot meet the requirements of technical indicators, and achieve low implementation costs and reduced costs. The effect of high production cost and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

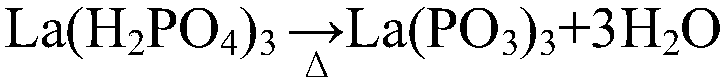

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: the preparation method of high-purity optical glass additive lanthanum metaphosphate:

[0046] Step 1, purifying lanthanum chloride raw material:

[0047] 1.1) Take industrial-grade lanthanum chloride raw material, put it into an enamel reaction kettle, add deionized water, heat and dissolve until the specific gravity is 1.15;

[0048] 1.2) After fully dissolving, when the temperature of the solution drops below 30°C, add a small amount of hydrogen peroxide, stir evenly, add a small amount of lanthanum carbonate, adjust the pH to 3.3, absorb and settle for 6 hours, remove the head and filter into another container Medium, standby; the volume ratio of hydrogen peroxide and lanthanum chloride added in this step is 2:1000; the volume ratio of lanthanum carbonate and lanthanum chloride is 5:1000;

[0049]1.3) Put the lanthanum chloride solution that has been filtered in step 1.2) into an enamel reaction kettle, add deionized water to adjust the specific gravi...

Embodiment 2

[0063] The preparation method of high-purity optical glass additive lanthanum metaphosphate:

[0064] Step 1, purifying lanthanum chloride raw material:

[0065] 1.1) Take industrial-grade lanthanum chloride raw material, put it into an enamel reaction kettle, add deionized water, heat and dissolve until the specific gravity is 1.18;

[0066] 1.2) After fully dissolving, when the temperature of the solution drops below 40°C, add a small amount of hydrogen peroxide, stir evenly, add a small amount of lanthanum carbonate, adjust the pH to 3.5, absorb and settle for 6 hours, remove the head and filter into another container Medium, standby; the volume ratio of hydrogen peroxide and lanthanum chloride added in this step is 1.5:1000; the volume ratio of lanthanum carbonate and lanthanum chloride is 2:1500;

[0067] 1.3) Put the lanthanum chloride solution filtered by step 1.2) into an enamel reaction kettle, add deionized water to adjust the specific gravity of the solution to 1.1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap