I-shaped steel reinforced beam cantilevered scaffold

A technology of I-shaped steel beams and reinforced beams, which is applied to the accessories of scaffolding, scaffolding supported by house structures, and house structure supports, etc. Poor steel frame strength and other issues, to achieve the effect of reducing manufacturing and processing costs and construction costs, increasing use efficiency and practicability, and increasing stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

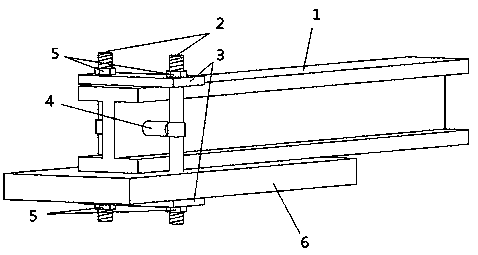

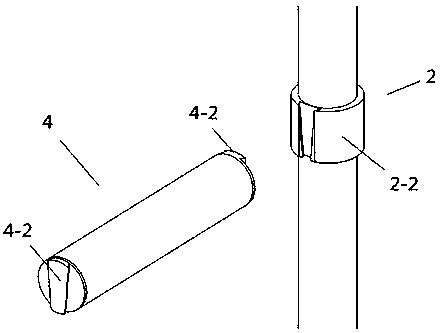

[0020] Such as Figure 1~Figure 4 As shown, a kind of I-beam reinforced beam cantilevered scaffold of the present invention comprises I-beam 1, vertical steel pipe 2, steel plate 3, horizontal steel pipe 4, nut 5, concrete floor slab 6, hollow plastic pipe 7, I-beam The steel beam 1 is placed on the concrete floor 6, and one end is protruded, and the protruded end is the head and the other end is the tail. There is a circular opening on the web plate at the tail of the I-shaped steel beam 1, and two steel plates 3 are respectively placed on the I-shaped steel beam. The upper part of the tail and the lower part of the concrete floor 6, the long side direction of the steel plate 3 is perpendicular to the long side direction of the I-shaped steel beam 1, the vertical direction of the two steel plates 3 corresponds vertically, and the length of the steel plate 3 is greater than the width of the flange plate of the I-shaped steel beam 1 , there are two circular through openings at ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap