Internal locking type drill pipe

A drill pipe and internal locking technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of complex structure, many connecting structural parts, inconvenient manufacture and use, etc., to achieve clear division of labor, convenient disassembly and assembly, Simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

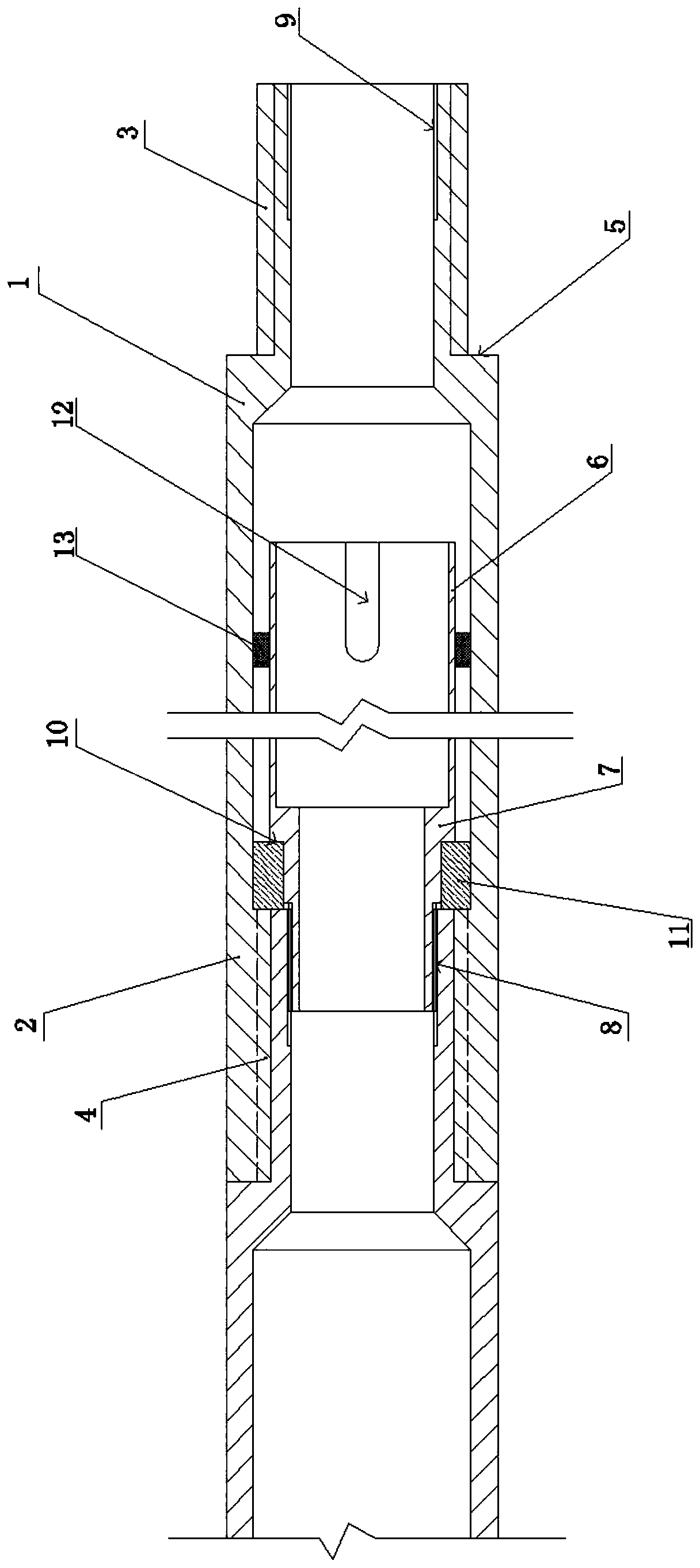

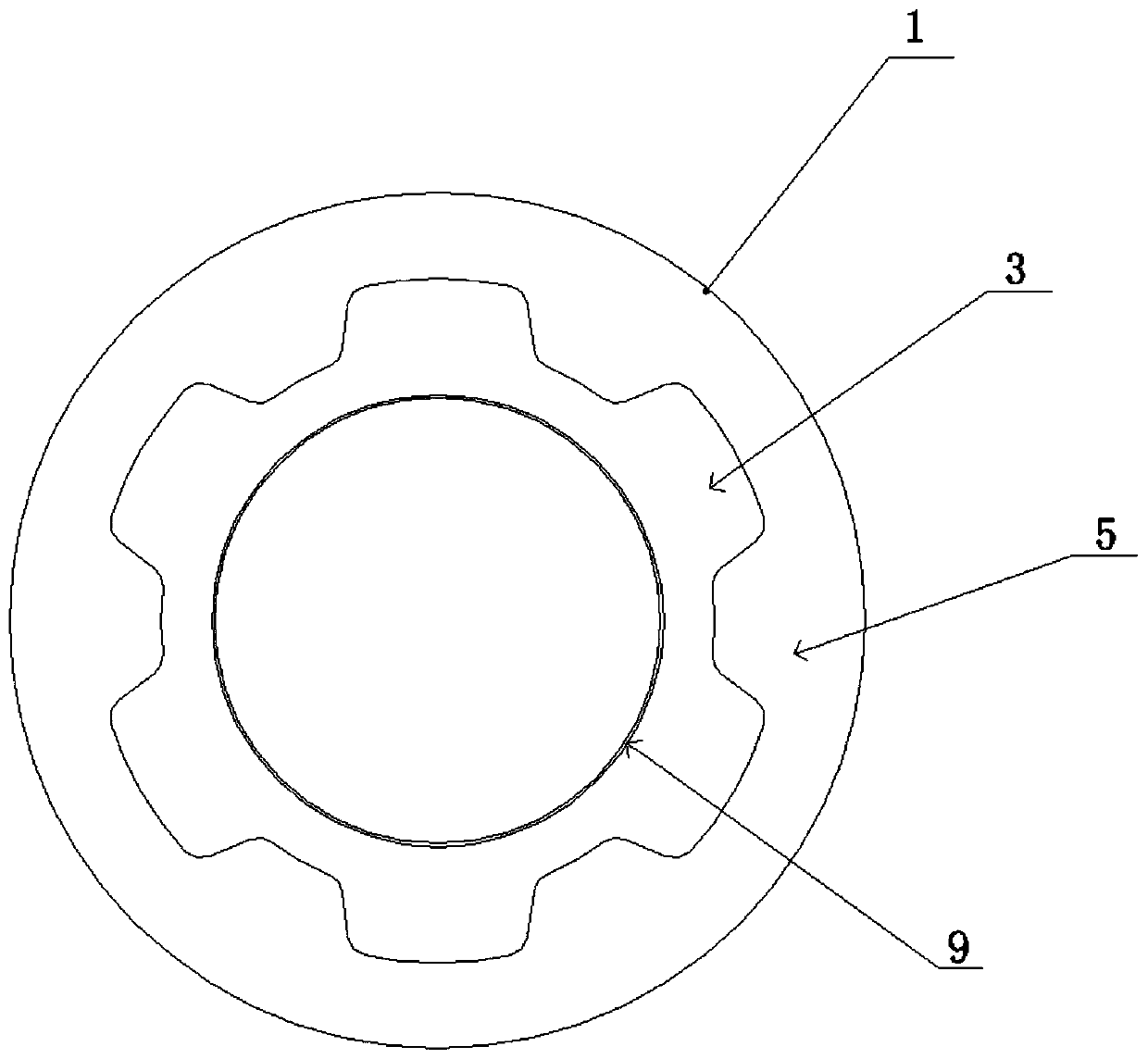

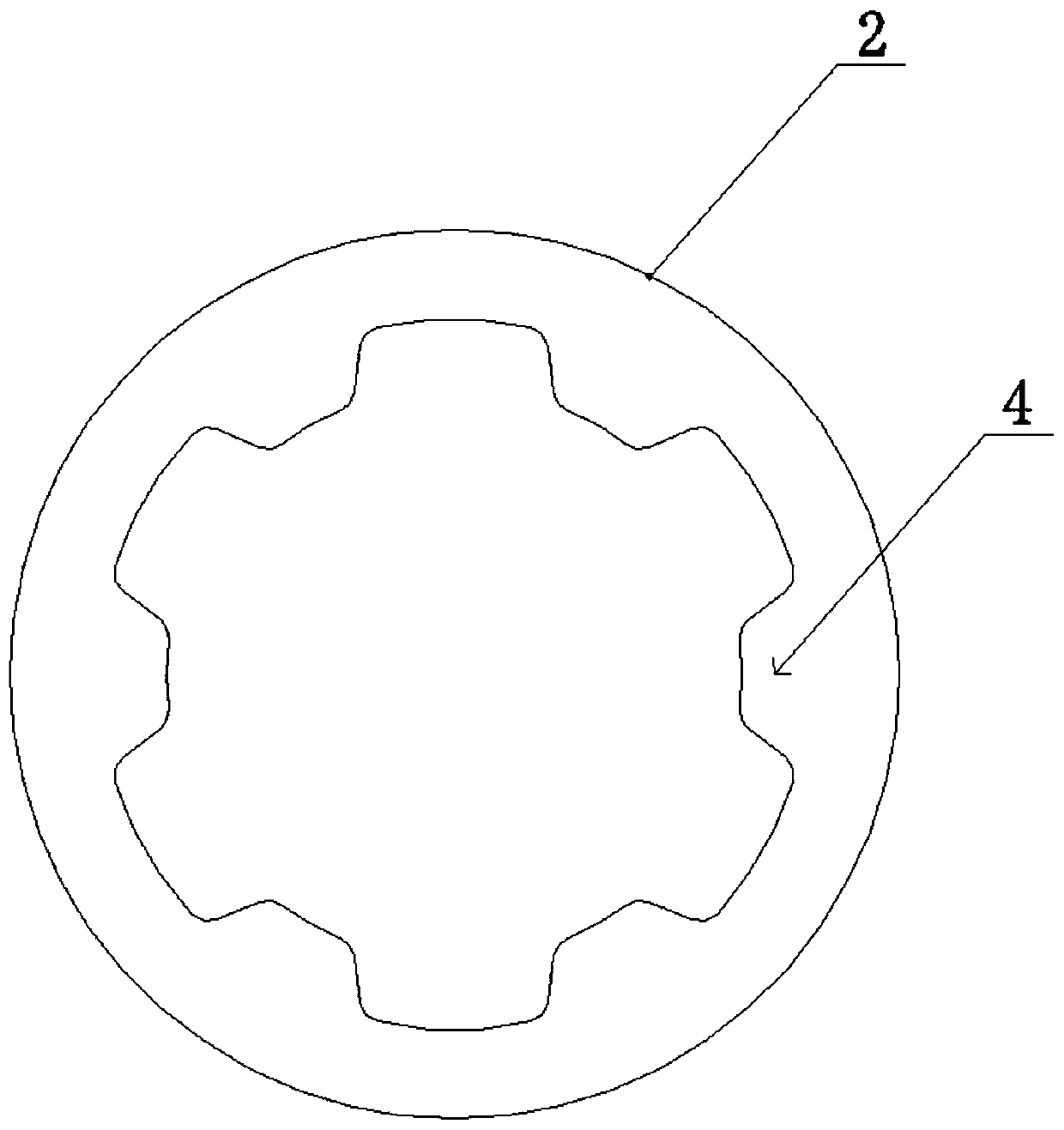

[0015] An inner locking drill pipe, refer to figure 1 , figure 2 and image 3 , including the male joint 1 and the female joint 2 at both ends of the drill pipe body, the male joint 1 is provided with a torsion-transmitting external spline 3, and the female joint 2 is provided with a torsion-transmitting internal spline matching the above-mentioned torsion-transmission external spline 3 4. A limiting shoulder 5 is provided on the male joint 1 at the root of the twisting external spline 3, and a mounting pipe 6 is concentrically provided in the drill pipe body. The end of the mounting pipe 6 close to the female joint 2 is fixed with an external thread 8 of the locking joint 7, the inner wall of the male joint 1 is provided with an internal thread 9 matching the external th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap