Double overrunning clutch shaft sleeve output automatic speed changing electric drive system with input of planetary gear train

A technology of electric drive system and planetary gear train, applied in the direction of vehicle gearbox, gear transmission, control/regulation system, etc., to achieve the effect of improving overall efficiency, smooth load change and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

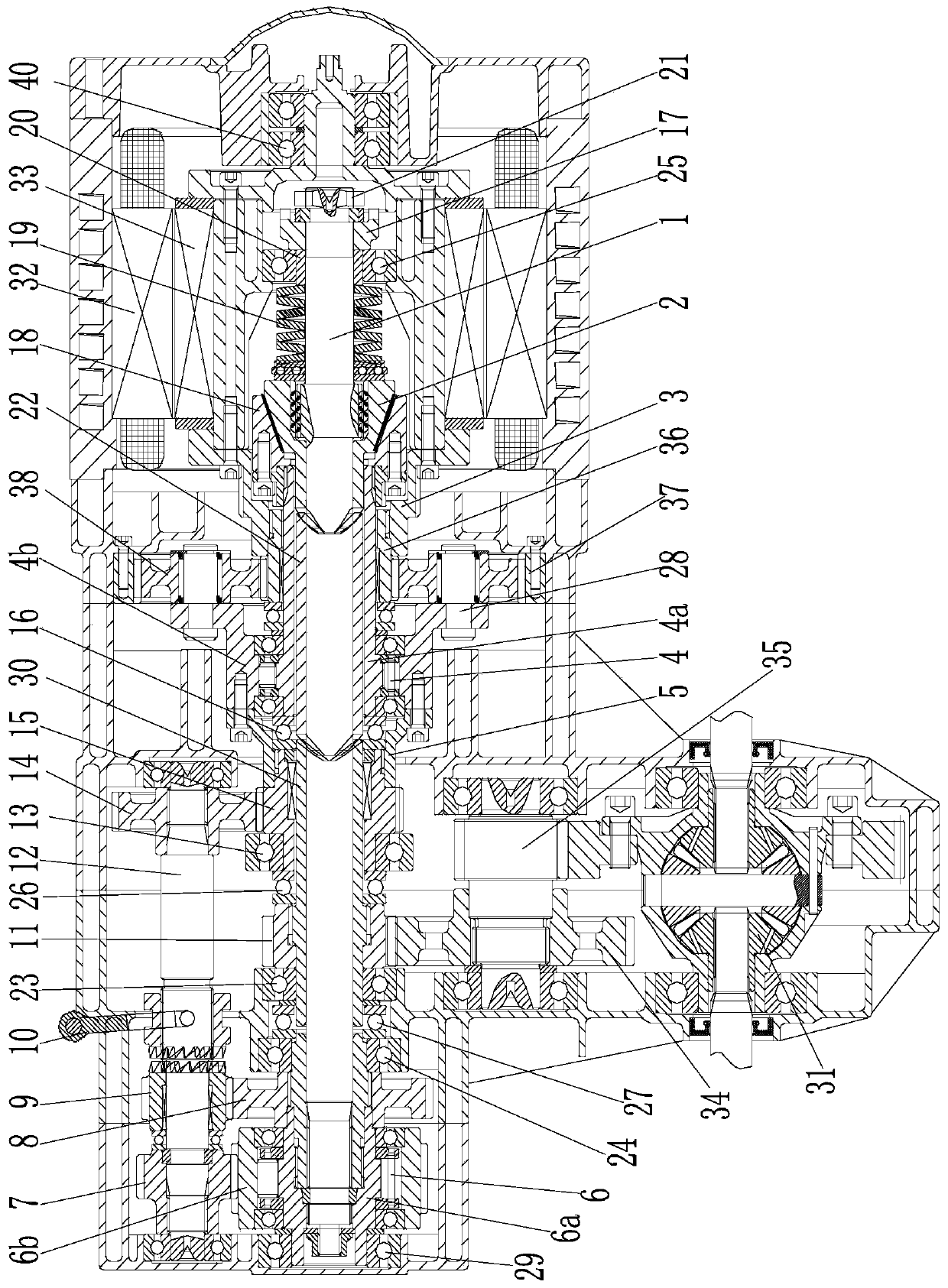

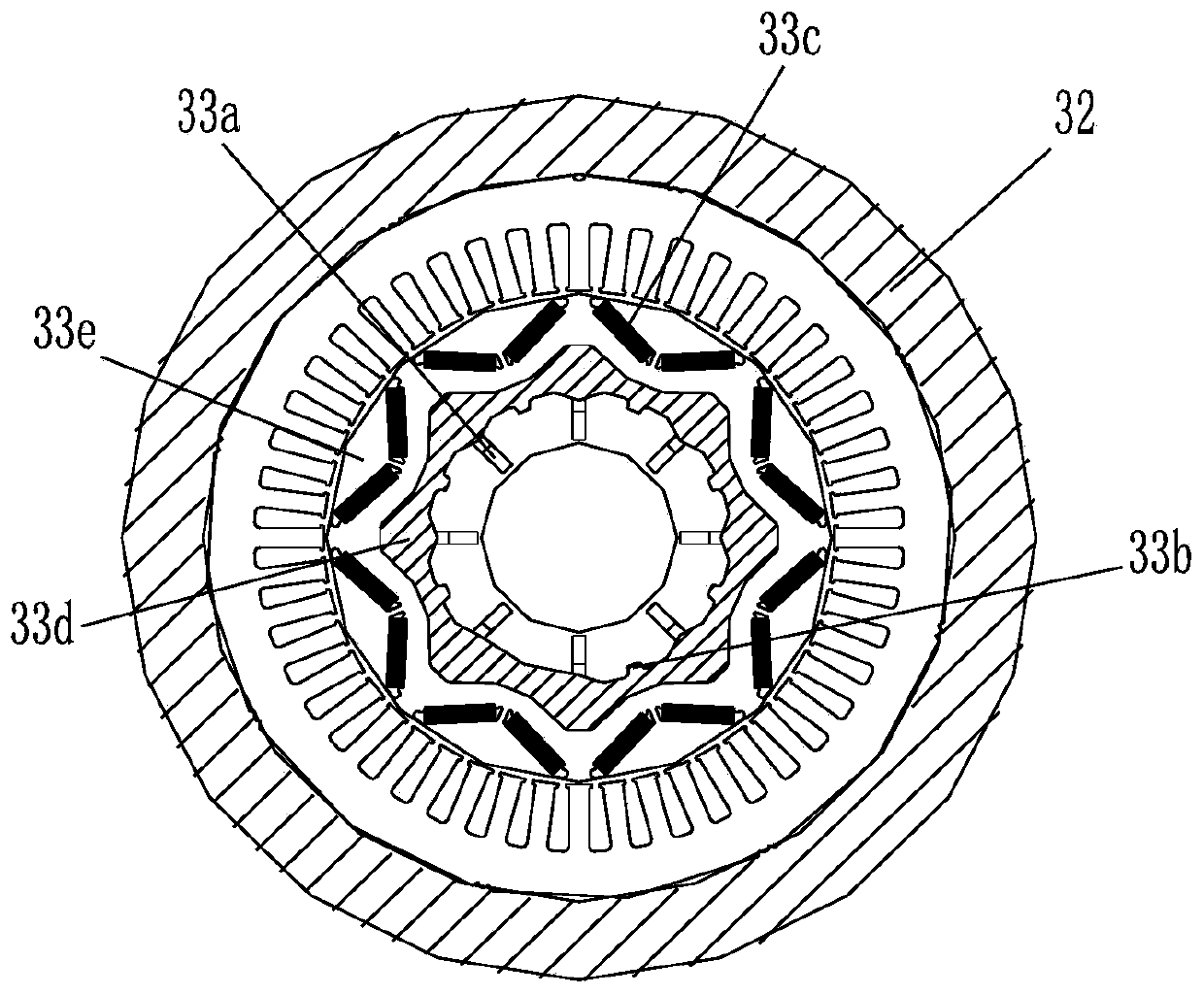

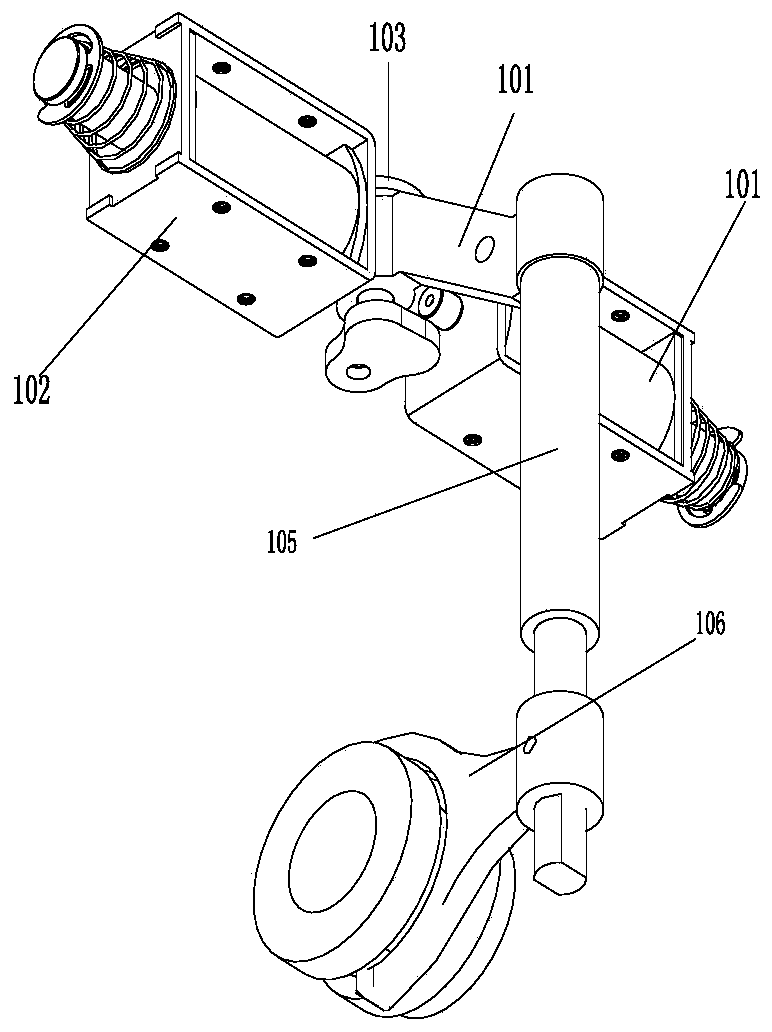

[0045] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 is the transverse section view of the drive motor, image 3 It is a schematic diagram of the electromagnetic shifting structure, Figure 4 The cross-sectional view of the position electromagnetic shifting structure, as shown in the figure: the double overrunning clutch sleeve output automatic variable speed electric drive system input by the planetary gear train of the present invention includes a casing, a drive motor and a transmission, and the transmission includes a main shaft 1 and a main shaft 1 The transmission system on the upper gear, the transmission system includes a planetary gear train, a low gear transmission mechanism, a reverse gear transmission mechanism and an adaptive transmission assembly;

[0046] The adaptive transmission assembly includes a driven friction member 2, an active friction member 18 and a variable speed elastic element 19;

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com