Ferrule type hydraulic pipe joint

A hydraulic pipe joint and ferrule-type technology, which is applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problem of no safety block in maintenance, and the installation of ferrule-type hydraulic pipe joints is not flexible enough in three directions, etc. Problems, to achieve the effect of improving safety and practicality, improving sealing performance and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

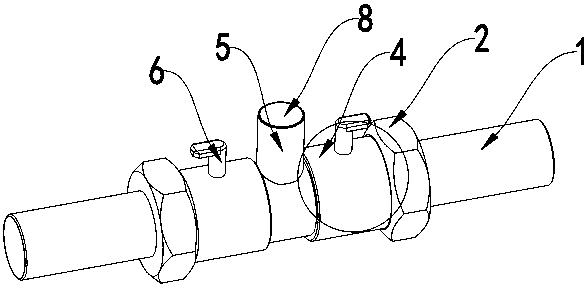

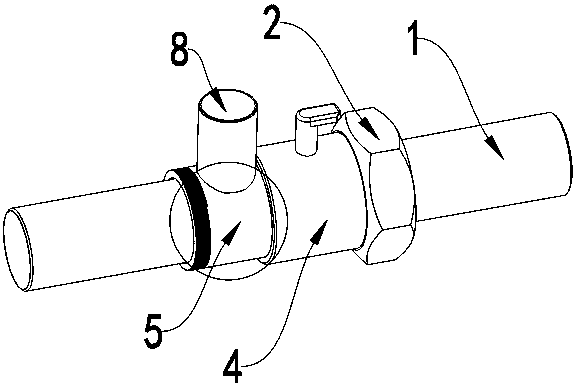

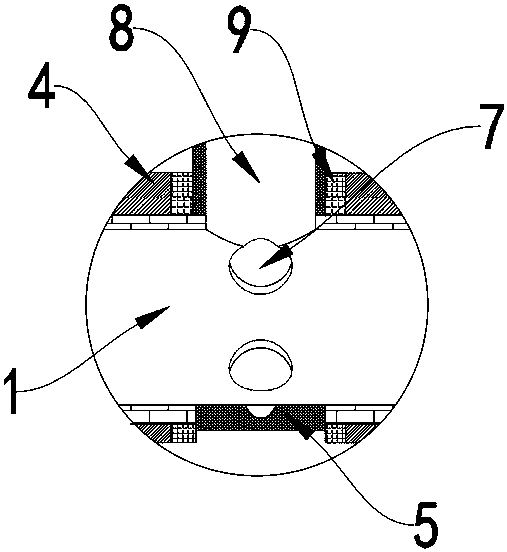

[0028] see Figure 1-4 , an embodiment provided by the present invention: a ferrule-type hydraulic pipe joint, including a hydraulic pipe 1, the outer surface of the hydraulic pipe 1 is provided with a transfer hole 7, and the outer surface of the transfer hole 7 is installed with a rotating pipe 5, through the installation The cooperation between the hydraulic pipe 1 and the rotating pipe 5 is installed by rotating the rotating pipe 5 and adjusting the required angle, so that the device is flexible when installed in the third direction. Rubber washers 9 are installed at both ends, and connecting pipes 4 are installed at both ends of the rubber washer 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com