Photogrammetric system based on speckle projection

A photogrammetry and speckle technology, applied in measurement devices, image data processing, instruments, etc., can solve the problem of inability to accurately match and detect, and achieve the effect of reducing the amount of calculation, improving the measurement efficiency, and improving the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

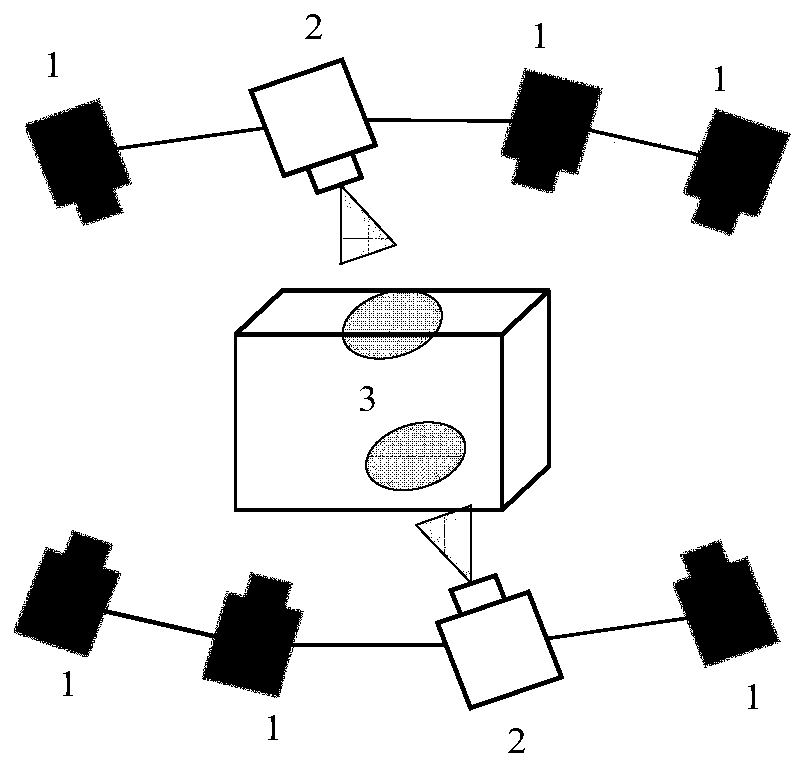

[0048] A photogrammetry system based on speckle projection, comprising a processor, a fixed frame, a speckle projector 2 fixedly installed on the fixed frame, and a plurality of cameras 1;

[0049] The speckle projector 2 can project speckle to the area to be tested; its number is 1, 2 or more, and the projection points can cover all the areas to be tested;

[0050] A plurality of cameras 1 respectively collect images in their field of view from multiple angles, and send the images to the processor;

[0051] The processor performs the following processing on the received image data to obtain the three-dimensional information of the features in the area to be tested:

[0052] 1) The conversion relationship between the multi-camera coordinate system and the workpiece coordinate system respectively established based on the camera external parameters;

[0053] 2) Based on the workpiece 3 digital model, the position of each feature point in the workpiece coordinate system is conve...

Embodiment 2

[0066] A photogrammetry system based on speckle projection, comprising a processor, a fixed frame, a speckle projector 2 fixedly installed on the fixed frame, and a plurality of cameras 1;

[0067] The speckle projector 2 can project speckle to the area to be tested; its number is 1, 2 or more, and the projection points can cover all the areas to be tested;

[0068] A plurality of cameras 1 respectively collect images in their field of view from multiple angles, and send the images to the processor;

[0069] The processor performs the following processing on the received image data to obtain the three-dimensional information of each feature to be tested in the area to be tested, and the feature to be tested is an obvious feature or an inconspicuous feature:

[0070] 1) Call the conversion relationship between the multi-camera coordinate system and the workpiece coordinate system respectively established based on the camera external parameters;

[0071] 2) Based on the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com