Geosynthetics construction damage test device and method

A geosynthetic material and testing device technology, applied in measurement devices, analytical materials, preparation of samples for testing, etc., can solve the problems of no compaction, single compaction function, inability to change the loading vibration frequency and power, etc., to ensure the test Result, the effect of the force state is clear, the concept is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

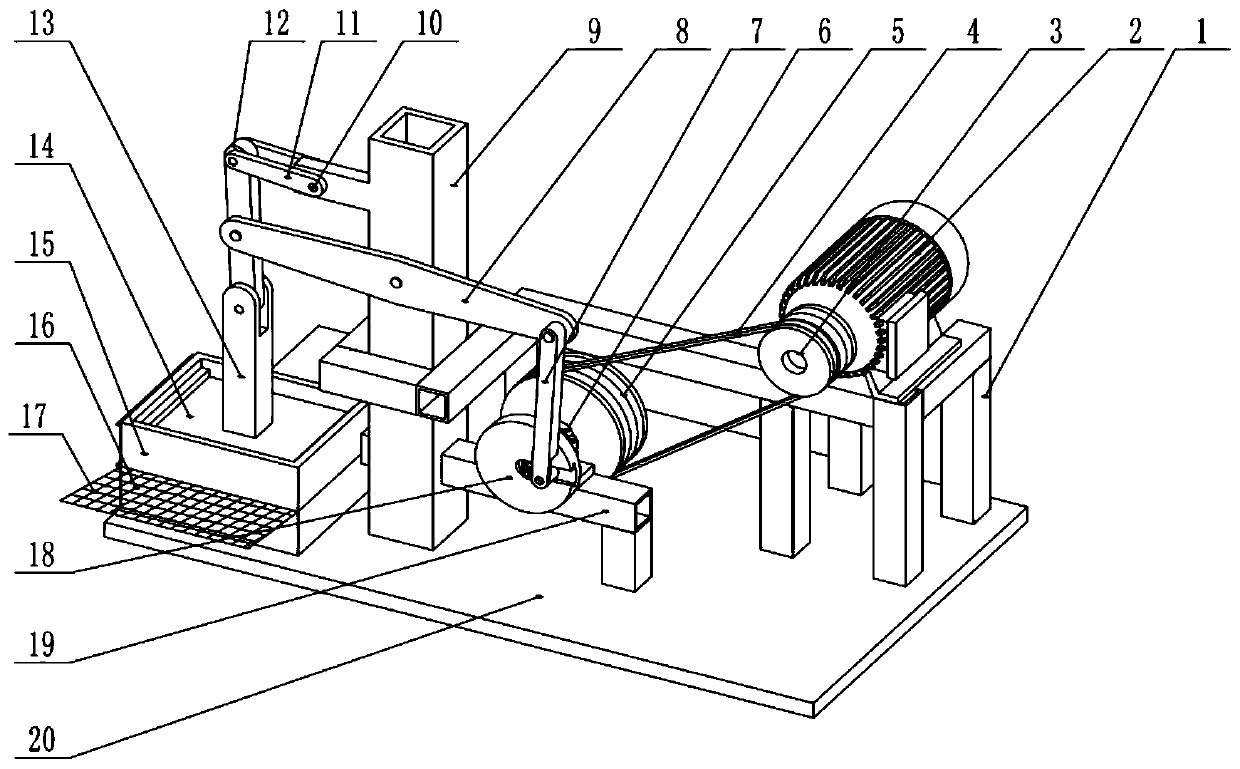

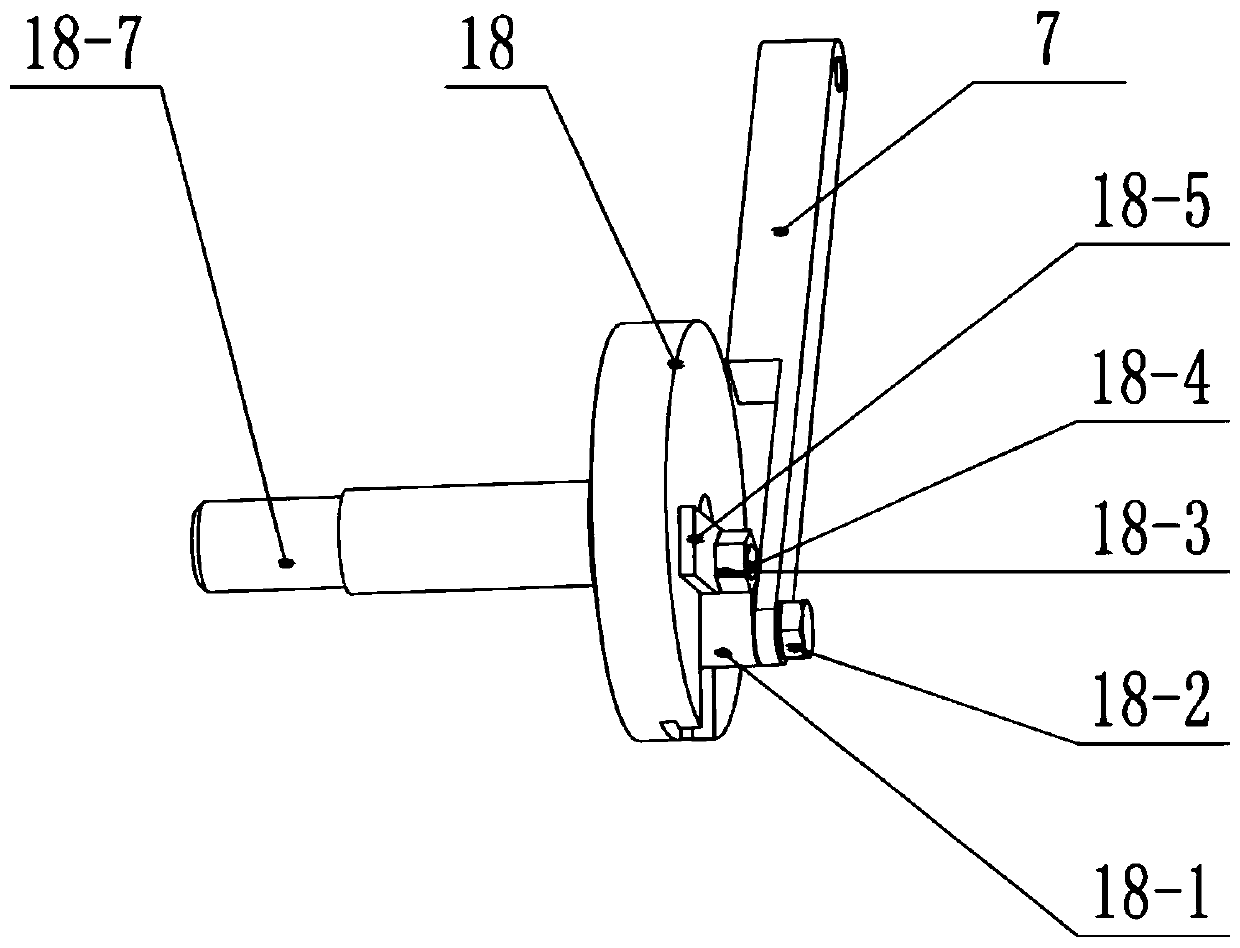

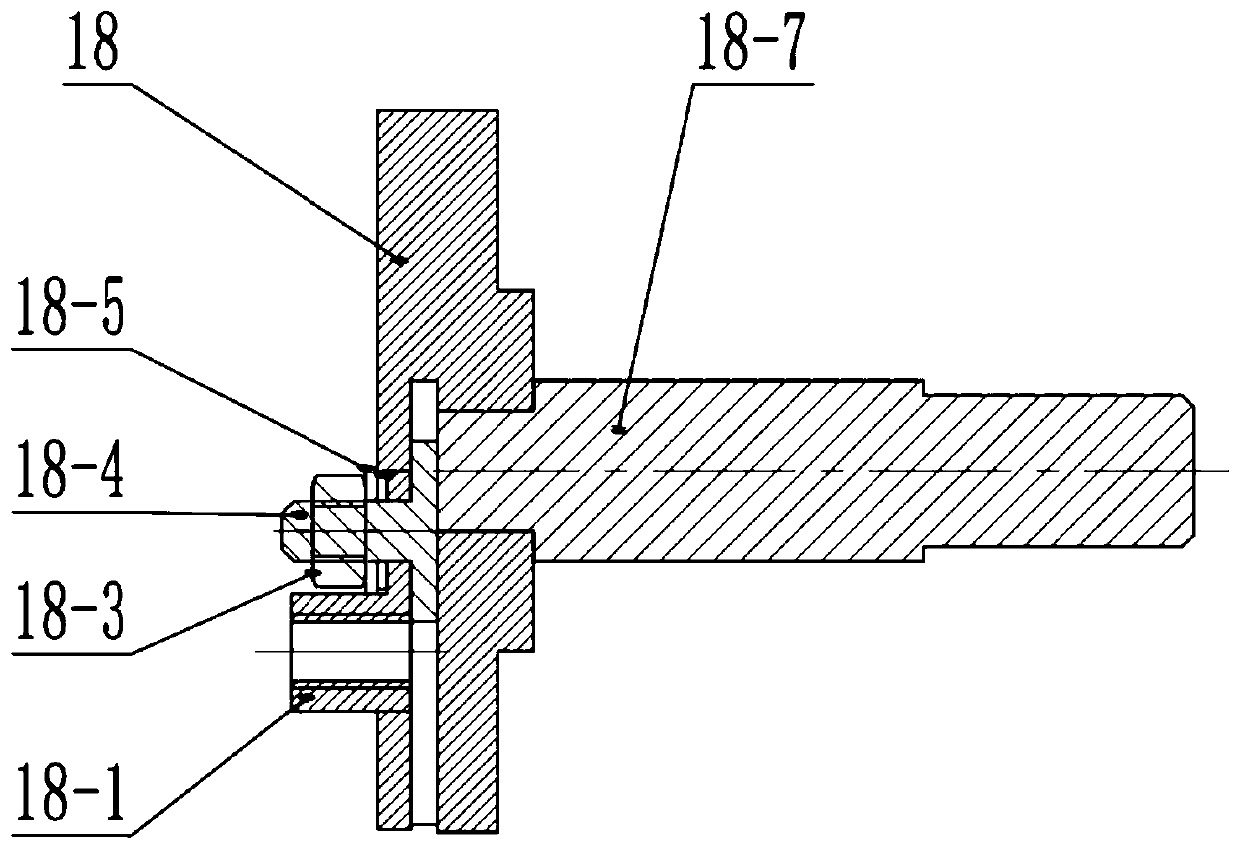

[0044] refer to figure 1 A construction damage test device for geosynthetic materials includes a support assembly, a combined steel box, a loading device and a driving device arranged thereon.

[0045] The combined steel box is used to fill the rammed earth, and the geosynthetic material 17 is laid between the rammed earth, the driving device is connected with the loading device, the driving device is used to provide power for the loading device, and the loading device is used for the geotechnical The synthetic material 17 applies pressure.

[0046] The bracket assembly includes a steel base plate 20, and a motor mount 1, a column 9 and an eccentric device support 19 arranged on the top, the drive device is installed on the motor mount 1, and the output shaft of the drive device is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com