Detection method for content of nitric acid insoluble substances in high-purity silver ingot

A detection method and technology for silver ingots, applied in the direction of removing certain components such as weighing, measuring devices, instruments, etc., can solve the problems of inaccurate detection results and high detection costs, so as to solve the problems of high cost, reduce operation steps, and detect Reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) 5 ± 0.1kg high-purity silver ingots are packed into graphite boats;

[0058] (2) Put the graphite material boat equipped with high-purity silver ingots into a high-temperature furnace at 1100 ° C and protected by a nitrogen atmosphere, and the effective temperature zone of the high-temperature furnace has a length of 750 cm;

[0059] (3) The push rod in the high-temperature furnace pushes the graphite boat containing high-purity silver ingots from the entrance of the high-temperature furnace to the exit of the high-temperature furnace at a pushing speed of 5cm / min. Every time the push rod is pushed for 30 minutes, stop pushing for 30 seconds, and then continue to move forward promote;

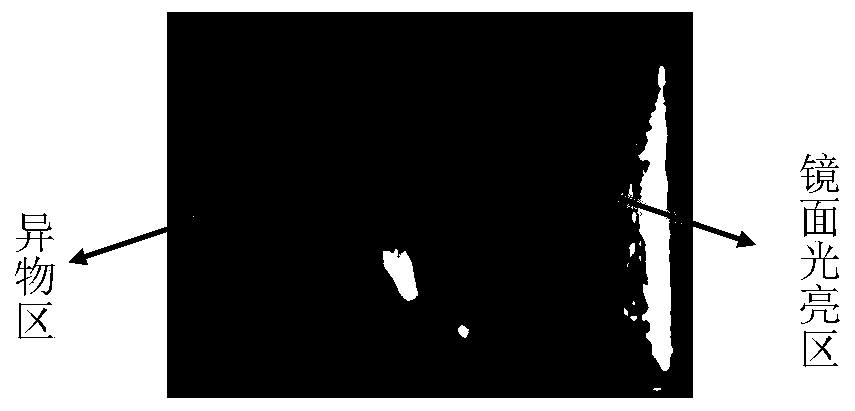

[0060] (4) When reaching the exit of the high-temperature furnace, observe the appearance of the upper surface of the silver ingot in the graphite material boat, and measure it with a ruler, such as Figure 5 , the total length of the silver ingot out of the furnace is about 20cm, w...

Embodiment 2

[0062] (1) 5 ± 0.1kg high-purity silver ingots are packed into graphite boats;

[0063] (2) Put the graphite material boat equipped with high-purity silver ingots into a high-temperature furnace at 1100 ° C and protected by a nitrogen atmosphere, and the effective temperature zone of the high-temperature furnace has a length of 750 cm;

[0064] (3) The push rod in the high-temperature furnace pushes the graphite boat containing high-purity silver ingots from the entrance of the high-temperature furnace to the exit of the high-temperature furnace at a pushing speed of 5cm / min. Every time the push rod is pushed for 30 minutes, stop pushing for 30 seconds, and then continue to move forward promote;

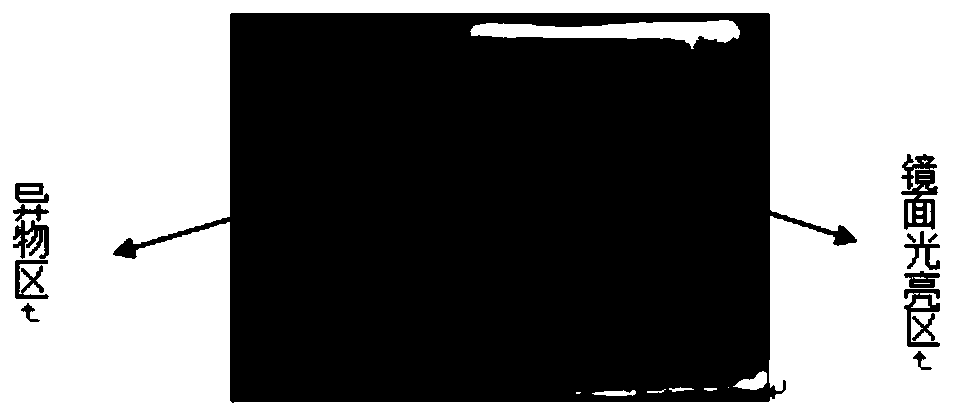

[0065] (4) When reaching the exit of the high-temperature furnace, observe the appearance of the upper surface of the silver ingot in the graphite material boat, and measure it with a ruler, such as Image 6 , the total length of the silver ingot out of the furnace is about 20cm, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com