Workplace harmful gas health risk quantitative evaluation system and evaluation method thereof

A workplace, harmful gas technology, applied in the field of on-site hazardous gas monitoring system and its monitoring and evaluation, can solve the problems of theoretical model research and experiment, quantitative evaluation without construction of monitoring system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions adopted in the examples can be further adjusted as the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

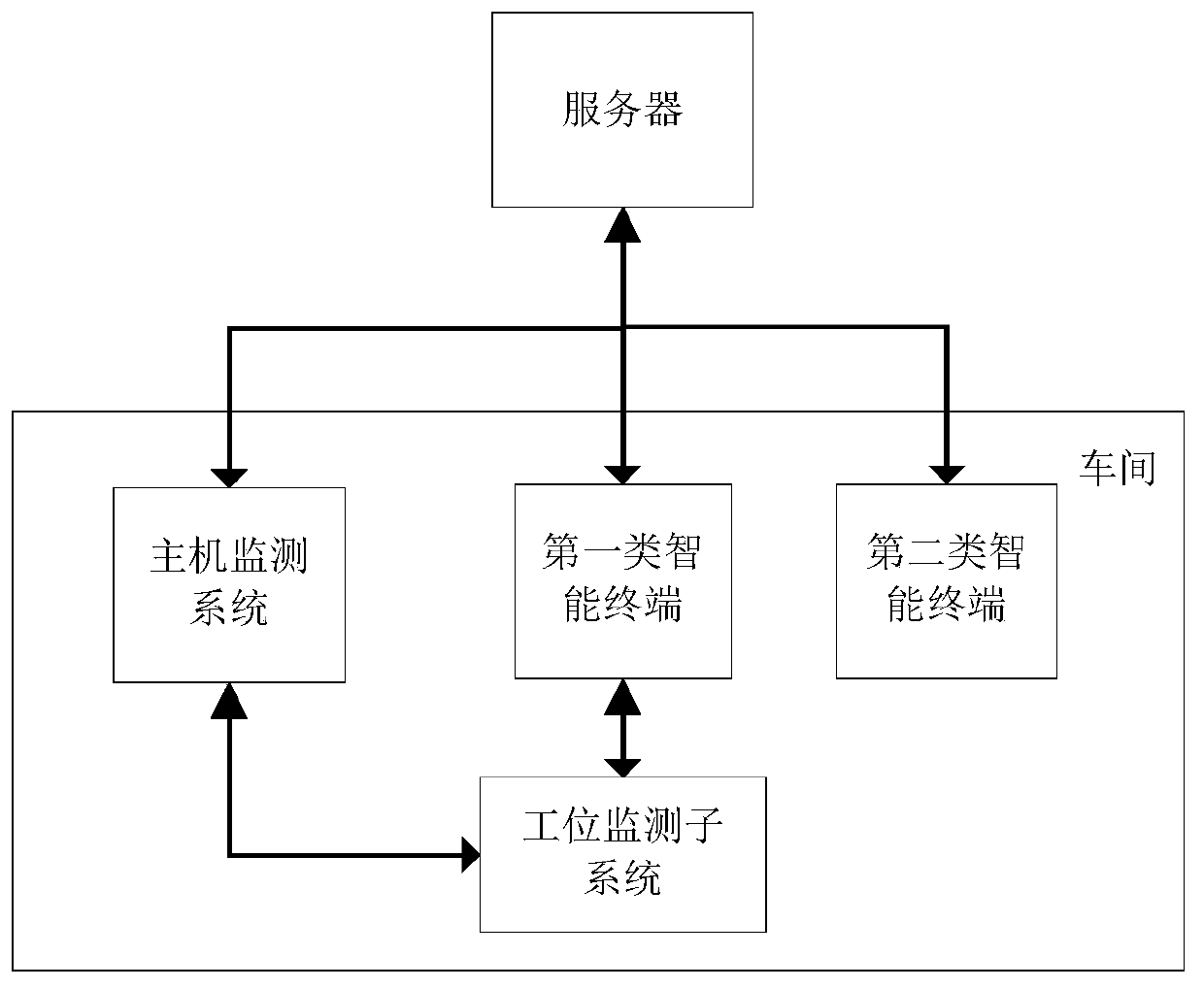

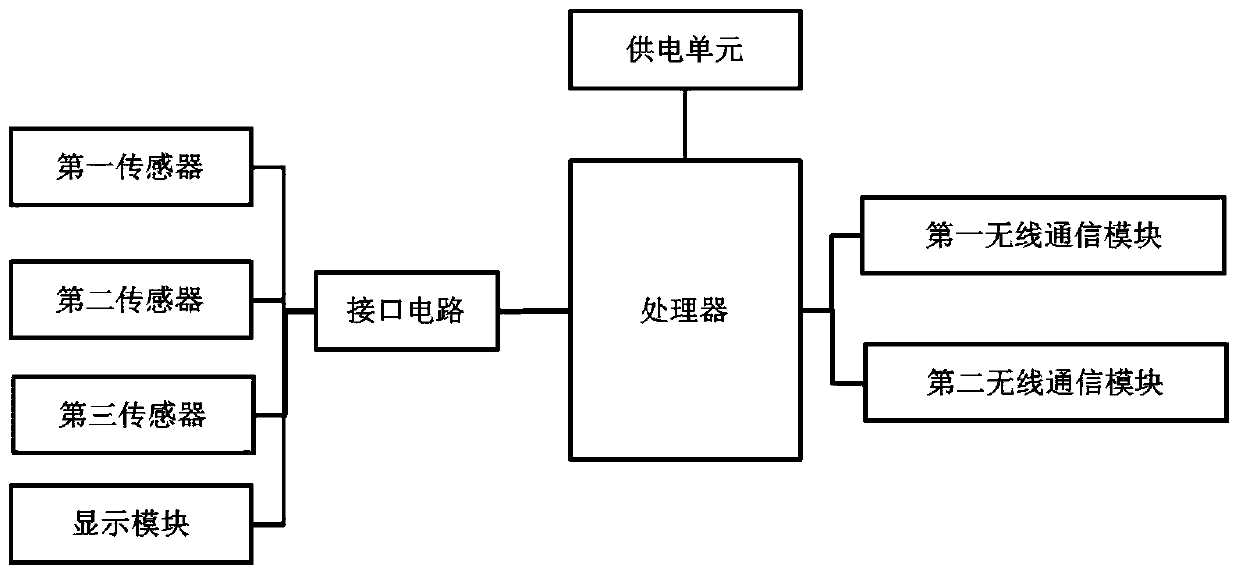

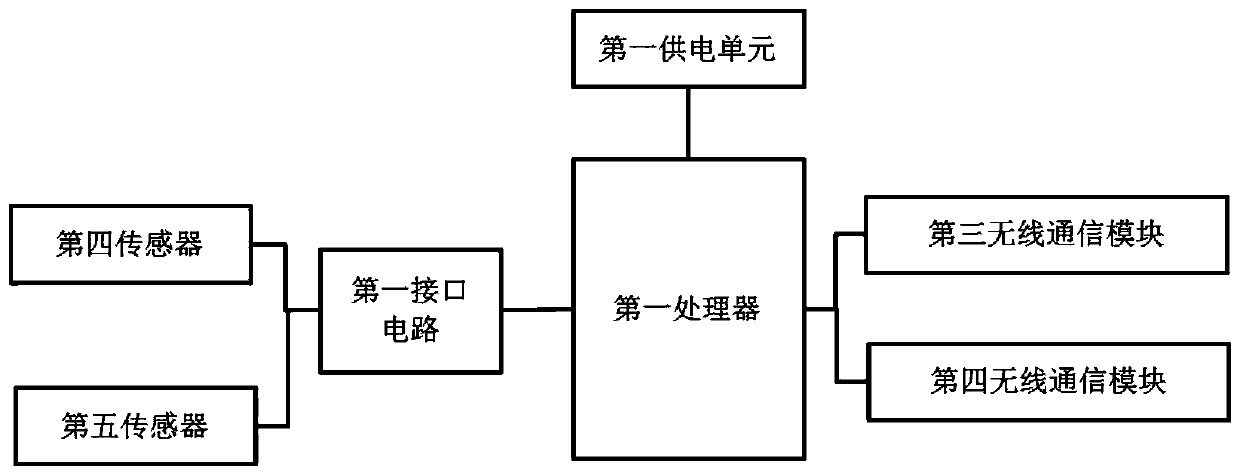

[0049] like figure 1 Shown is a module schematic diagram of a system for quantitative assessment of health risks of harmful gases in workplaces according to an embodiment of the present application. The system is used to monitor the concentration of harmful gases in workplaces (workshops). It includes servers, at least one workplace, and each workplace The site is equipped with a host monitoring system, several station monitoring subsystems, and several station monitoring subsystems are respectively matched to connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com