Mold molded surface through A face compensation method for optimizing surface quality of outer covering part of car body

A technology for outer cover and surface quality, applied in the field of mold profile over-A surface compensation, it can solve problems such as surface quality defects of body outer cover, and achieve the effect of ensuring overall aesthetics, improving surface quality, and compressing debugging cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A method for compensating mold surface over A surface for optimizing the surface quality of vehicle body outer covering parts: comprising the following steps:

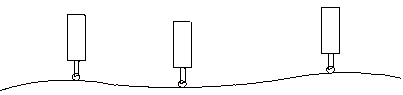

[0046] A1. Data measurement and analysis on the surface quality defects of the drawn parts of the body outer panel through precision measuring equipment ( Figure 1-Figure 3 );

[0047] A2. Use precision measuring equipment to measure and analyze the data on the surface A of the drawing die punch for the outer body panel ( Figure 1-Figure 3 );

[0048] A3. By comparing the surface quality defect data of the drawn part of the outer body cover with the data on the A side of the punch of the outer body cover drawing die, confirm the missing state of the A side of the punch of the drawing die of the outer body cover;

[0049]A4. Restore the reference state on the surface A of the drawing die punch of the body outer panel ( Figure 5 middle icon 2);

[0050] A5. Confirm the surface quality defect status of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com