High-precision rotary jacking tip

A high-precision, top-notch technology, applied in the direction of tailstock/top, turning equipment, tool holder accessories, etc., can solve problems such as the adverse effect of workpiece machining accuracy, small ejector pins, etc., to improve cooling effect, increase area, reduce effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

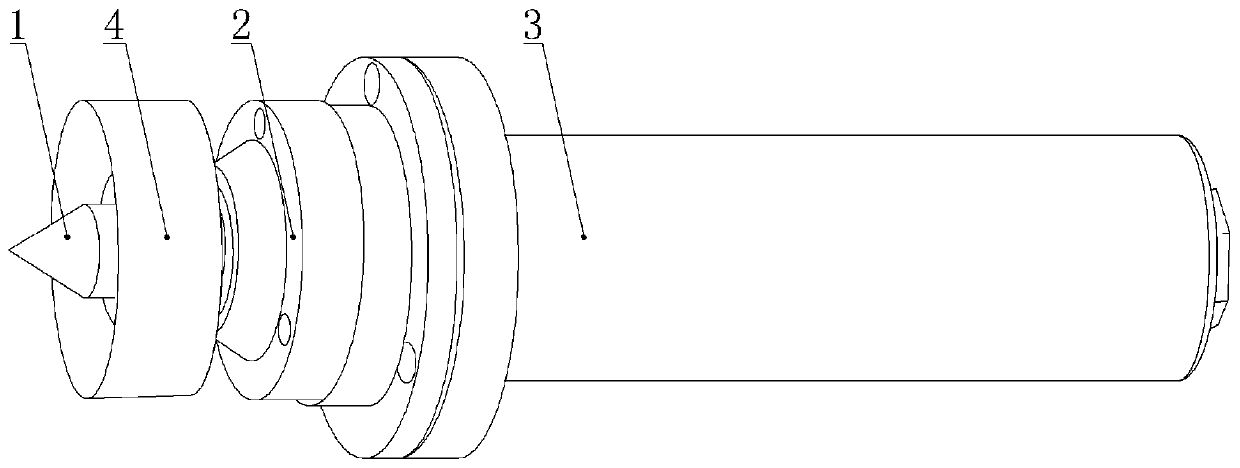

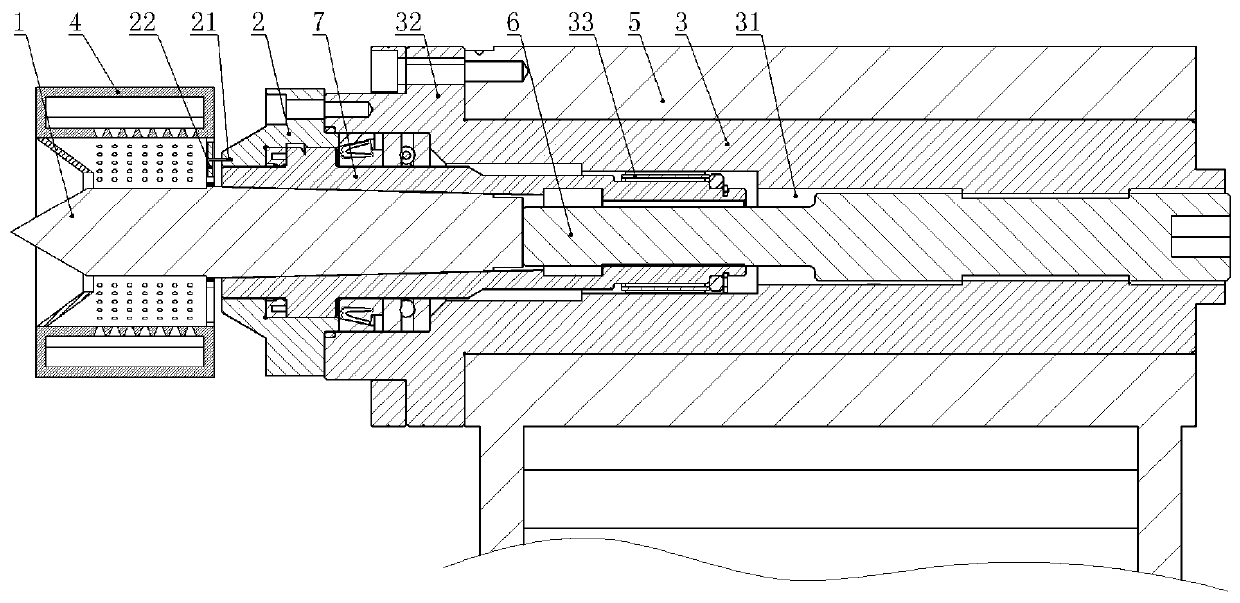

[0039] A high-precision rotating top, such as figure 1 and figure 2 As shown, including sleeve 3, mandrel 7, ejector rod 6, thimble 1 and protective cover 2, sleeve 3 is provided with installation hole, bearing hole and eccentric hole 31 in turn from left to right, installation hole, bearing hole and sleeve The barrel 3 is coaxial, and the eccentric hole 31 is set eccentrically relative to the sleeve 3 . The left end of the sleeve 3 is integrally formed with an annular connection plate 32, and several threaded holes are evenly distributed along the circumference of the connection plate 32. The sleeve 3 is inserted into the tailstock 5 of the machine tool. The right side wall of the connection plate 32 is connected to the left side of the tailstock 5. The walls are against each other, and the fixing of the sleeve 3 can be realized by screwing the bolts into the threaded holes and the tailstock 5 .

[0040] The mandrel 7 is installed in the mounting hole, the left end of the ...

Embodiment 2

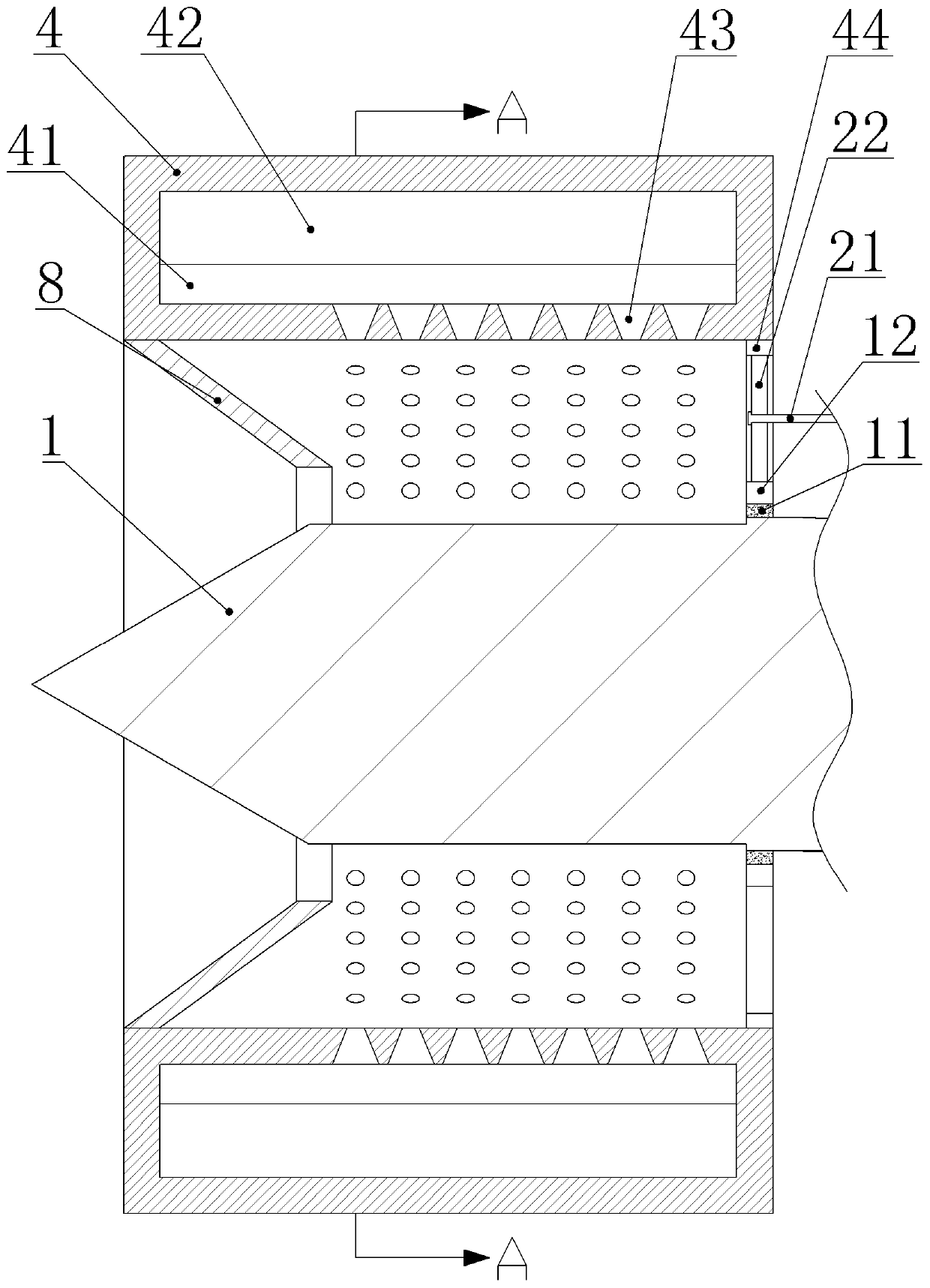

[0053] On the basis of Example 1, such as Figure 5 , Figure 6 and Figure 7 As shown, the mandrel 7 of the present embodiment is provided with an annular waterproof groove 71 on the side wall away from the thimble 1. The waterproof groove 71 is located at the left end of the mandrel 7. The section of the waterproof groove 71 along the axial direction of the mandrel 7 is wedge-shaped. The protective cover 2 The bottom is provided with a first channel 23 communicating with the waterproof groove 71. When water mist enters the connection gap between the protective cover 2 and the mandrel 7, the water mist enters the waterproof groove 71 and is finally discharged through the first channel 23 to avoid water The fog erodes the bearing 33 . The bottom of the protective cover 2 is provided with a second channel 24 aligned with the waterproof groove 71. The second channel 24 is located on the left side of the first channel 23. A push rod 25 is slid in the second channel 24. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com