Chuck used for die head threading machine clamping without damages

A wire threading machine, non-damaging technology, applied in the direction of thread cutting machine, metal processing equipment, thread cutting device, etc., to achieve the effect of ensuring neutrality, simple structure, and accurate clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

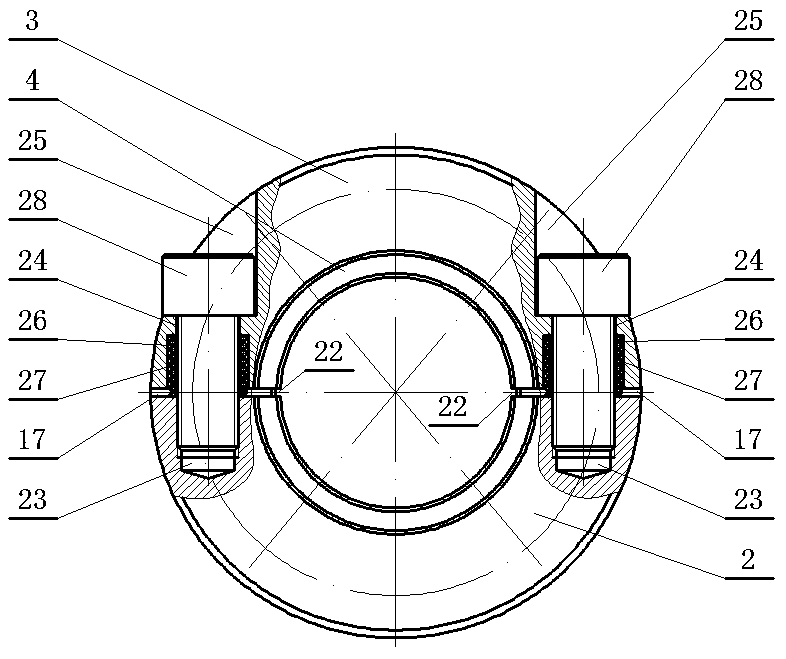

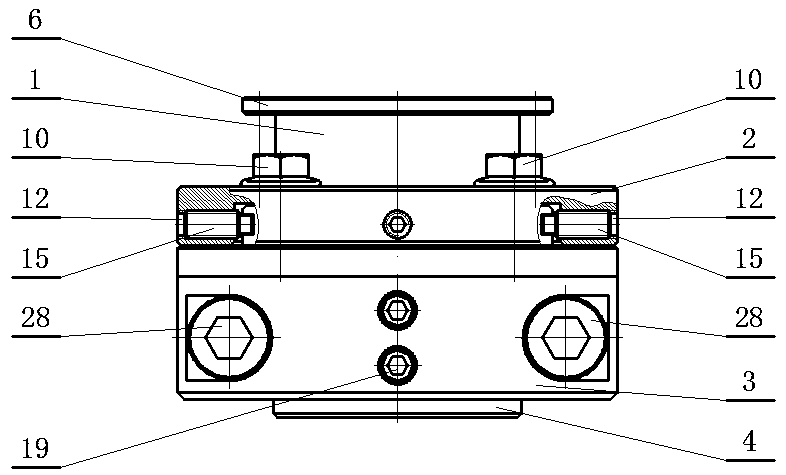

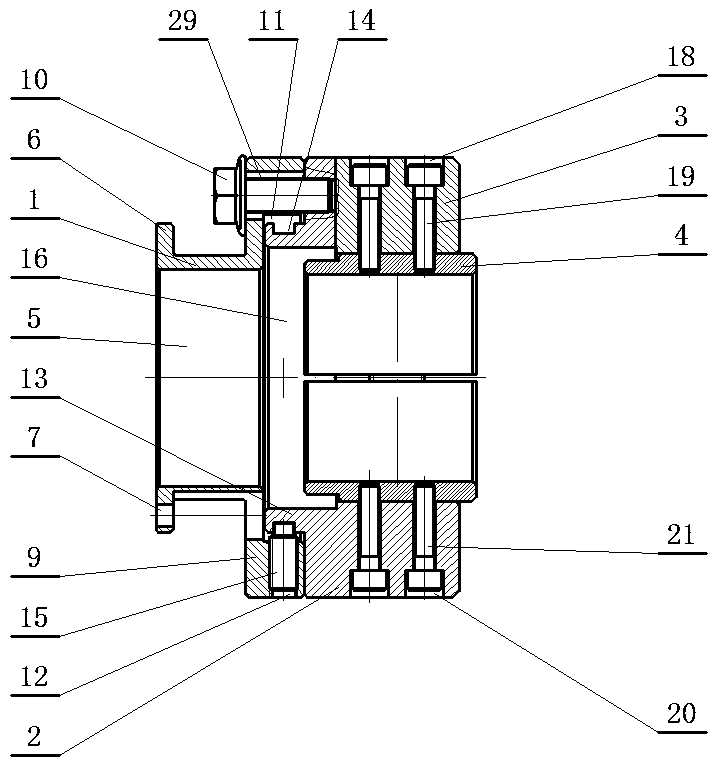

[0022] like Figure 1~Figure 4 As shown, the collet used for clamping the threading machine without damage includes a mounting plate 1, a jacket 2 and an inner sleeve 4, wherein the right end of the mounting plate 1 is coaxially equipped with a jacket 2, and the jacket 2 is placed and installed There are inner sleeves4.

[0023] Specifically, the mounting plate 1 has a through hole A5 along the axis, and its left end has an integral flange A6, and the flange A6 is distributed with a plurality of axial screw holes A7 along the disc, and the screw A8 passes through the screw. Fix the flange A6 on the end face of the main shaft of the threading machine after passing through the hole A7; the right end has an integrated flange B9, and the flange B9 has a plurality of axial bolt t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com