A high-efficiency curing device for concrete test blocks

A concrete test block, high-efficiency technology, applied in the direction of high-efficiency adjustment technology, heating methods, lighting and heating equipment, etc., can solve the problems of concrete test blocks providing the same humidity environment, such as differences in the curing strength of concrete test blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The invention will now be described in further detail with reference to the drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

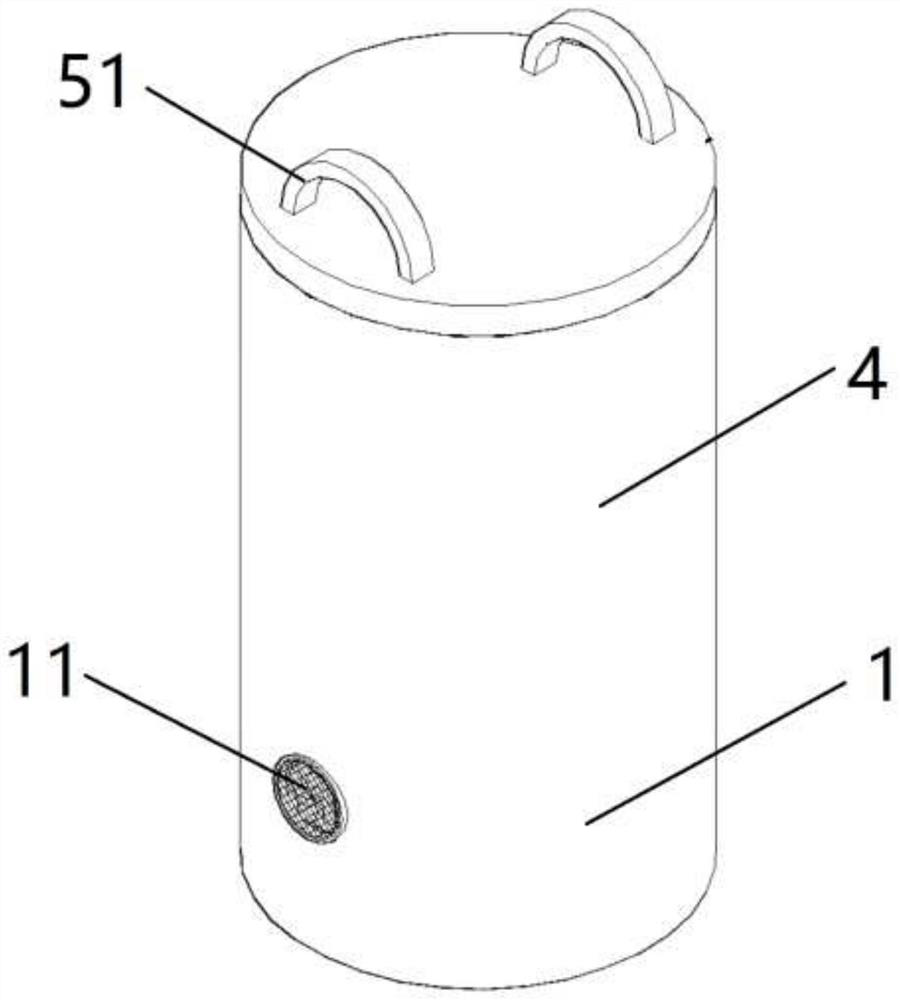

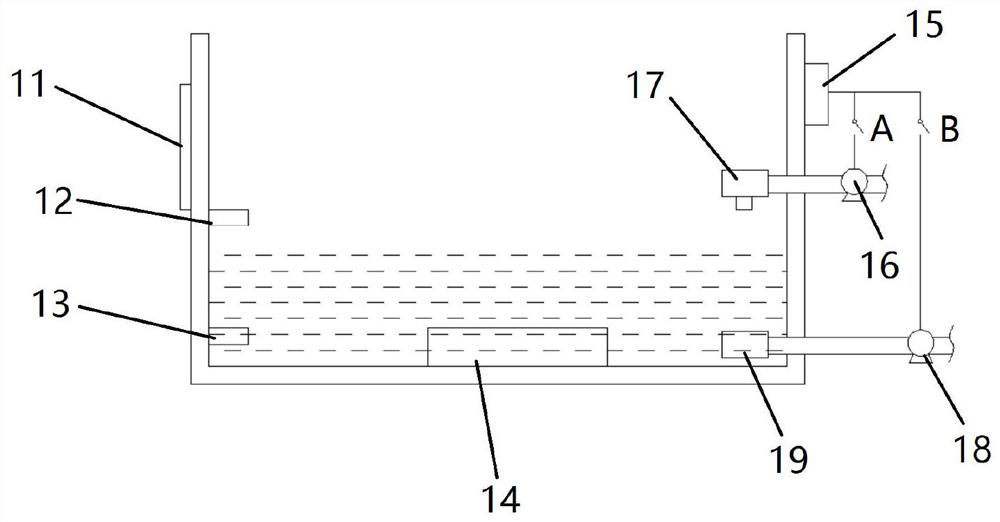

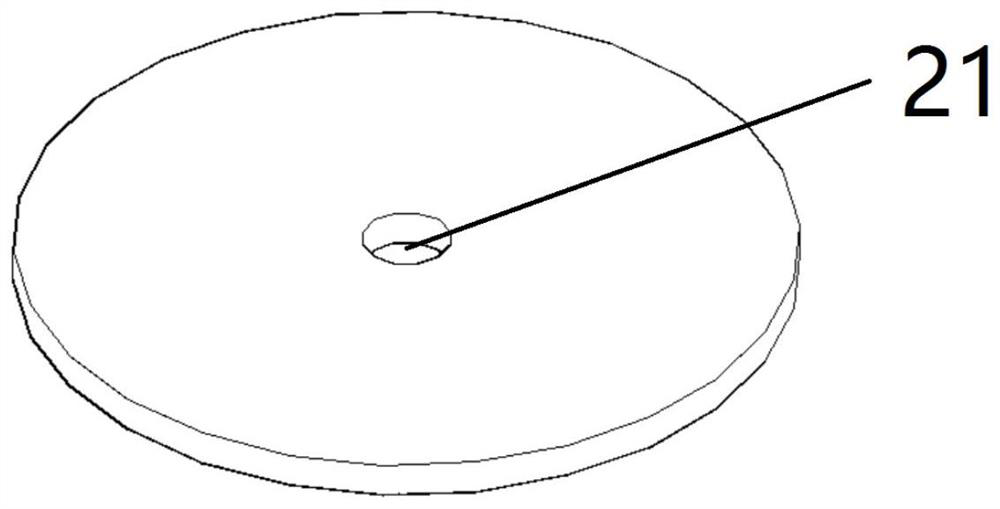

[0036]Such asFigure 1 - Figure 9 As shown, the present invention includes the following feature components: 1 is a humidifying portion, 2 being an intermediate plate, 3 is a rotary humidifier, 4 is a maintenance portion, 11 is a fan, 12 is a top water level sensor, 13 is a water level sensor, 14 is high Frequency ultrasonic generator, 15 is a controller, 16 is a first water pump, and 17 is an inlet, 18 is a second water pump, 19 is a water outlet, and a is a switch valve A, B is a switching valve B, 21 is a rotating vent, 31 is a wetting column, 311 is an exhaust hole, 32 is a cylindrical rotary plate, 33 is a circular drain hole, 34 is a rotating central block, 36 is a humidify cavity, 51 is a grip, 52 is a cover, 53 is a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com