Efficient laminating mechanism for corrugated boards for packaging

A technology for corrugated cardboard and packaging, applied in the direction of machining/deformation, etc., can solve the problems of adjusting the spacing between rolls, the quality of the finished product cannot meet the requirements of use, etc., and achieve the effect of ensuring quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

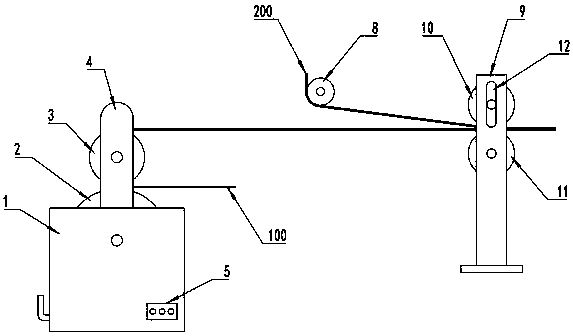

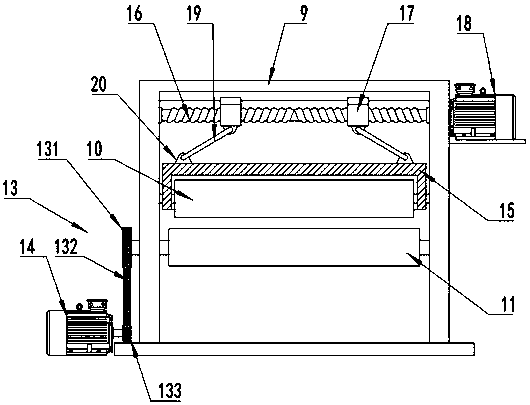

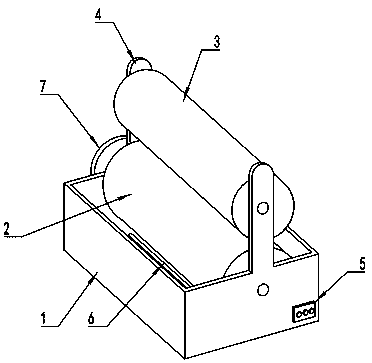

[0020] see Figure 1~3 , in an embodiment of the present invention, a high-efficiency bonding mechanism for corrugated cardboard for packaging includes a rubber box 1, a glue roller 2, a guide roller 8, a bonding roller frame 9, a squeeze roller 10, and a bonding roller 11. The gluing roller 2 is installed in the glue box 1, and the gluing roller 2 is driven to rotate by the driving motor 3. The top of the gluing roller 2 should exceed the liquid level of the glue in the glue box 1, and the top of the glue box 1 is also installed through the bracket 4. There is a turning guide roller 3, and there is a gap between the turning guide roller 3 and the glue roller 2 for the corrugated paper 100 to pass through. On the laminating roller frame 9, there are squeeze rollers 10 and laminating rollers 11 distributed up and down. A gap is reserved between the extruding rollers 10 and the laminating rollers 11 for corrugated paper 100 and liner paper 200 to pass through. The liner paper 2...

Embodiment 2

[0024] see image 3 , in the embodiment of the present invention, a high-efficiency bonding mechanism for corrugated cardboard for packaging, because in actual application, the glue in the glue box 1 is easily affected by the ambient temperature, resulting in differences in its flow properties, and the glue application effect will be serious Affected, therefore, a heating rod 6 for heating the glue liquid is installed in the glue box 1, and the heating rod 6 is controlled by a temperature control panel 5 arranged on the glue box 1 to ensure the temperature of the glue liquid in the glue box 1. constant.

[0025] Due to the consumption of the glue, the glue tank 1 is connected with a liquid feeding pipe, and at the same time, in order to ensure a constant glue level, a liquid level detection device is installed in the glue tank 1 .

[0026] Combining Examples 1-2, it is easy to know that the working principle of this technical solution is: after the corrugated paper 100 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com