Fabricated bridge deck structure

A prefabricated, stepped structure technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of difficult control of on-site construction quality, heavy workload of cast-in-place concrete, heavy maintenance and repair workload, etc., to achieve convenient hoisting and prefabrication Installation, fewer construction procedures, less lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

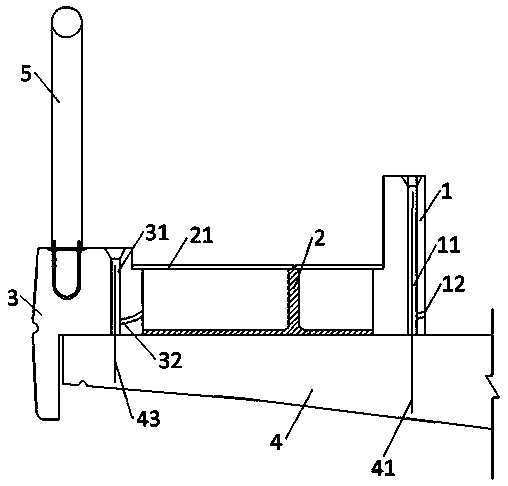

[0050] like figure 1 As shown, the protective wall 1 and the auxiliary foundation 3 are positioned through the prefabricated No. I reserved anchor hole 11 and No. II reserved anchor hole 31 and the No. I connector 41 and No. II connector 43 on the main beam 4, and then pass through the Grouting material is poured into No. 1 grouting hole 12 and No. 2 grouting hole 32 to realize fixed connection.

[0051] The cable duct 2 and the cover plate 21 are placed on the main beam 4 .

Embodiment 2

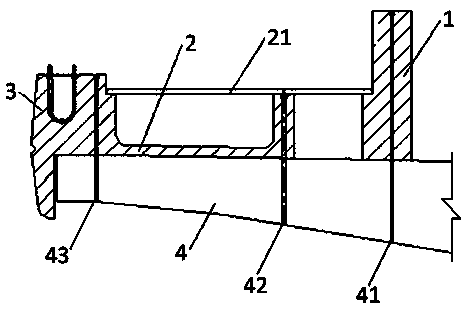

[0053] like figure 2 As shown, the protective wall 1 and the auxiliary foundation 3 are positioned through the prefabricated No. I reserved anchor hole 11 and No. II reserved anchor hole 31 and the No. I connector 41 and No. II connector 43 on the main beam 4, and then pass through the Grouting material is poured into No. 1 grouting hole 12 and No. 2 grouting hole 32 to realize fixed connection.

[0054] The cable duct 2 and the subsidiary foundation 3 are prefabricated together, and a gap is formed between the outer side of the cable duct 2 and the protective wall 1 .

Embodiment 3

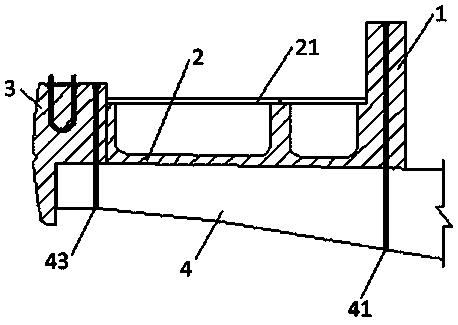

[0056] like image 3 As shown, the protective wall 1 and the auxiliary foundation 3 are positioned through the prefabricated No. I reserved anchor hole 11 and No. II reserved anchor hole 31 and the No. I connector 41 and No. II connector 43 on the main beam 4, and then pass through the Grouting material is poured into No. 1 grouting hole 12 and No. 2 grouting hole 32 to realize fixed connection.

[0057] The cable trough 2 is prefabricated with the protective wall 1 , and the outer side of the cable trough 2 is attached to the auxiliary foundation 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com