Municipal rainwater pipeline assembly module and construction method

A construction method and rainwater technology, applied in the sewer system, waterway system, water supply device, etc., can solve the problems of increasing the cost of urban road operation and maintenance, inconvenient traffic of urban vehicles, and cracking on the road surface. The effect of fast progress and simple on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

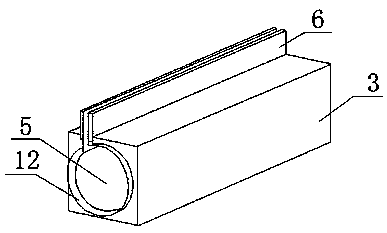

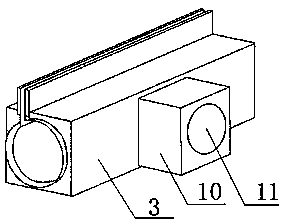

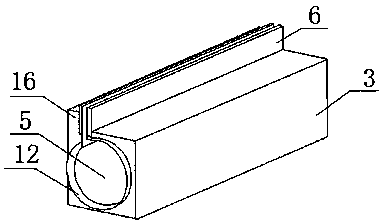

[0040] Municipal rainwater pipeline assembly module of the present invention comprises four kinds of structural forms, is respectively assembly module A3, assembly module B, assembly module C and assembly module D, introduces the structure of these four kinds of assembly modules in detail below respectively:

[0041] The assembly module A3 comprises several, fixed together end to end. The assembly module A3 is provided with a hollow cavity A5 from left to right. The hollow cavity A5 deviates from the highest point of the upper end and communicates with a channel 15 upwards. A template 6 is respectively fixed on both sides of the cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com