An anti-expansion ball valve

A ball valve, anti-expansion technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problems of reduced ball valve utilization, waste of resources, cracking, etc., to improve the utilization rate and service life, reduce serious waste. , the effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

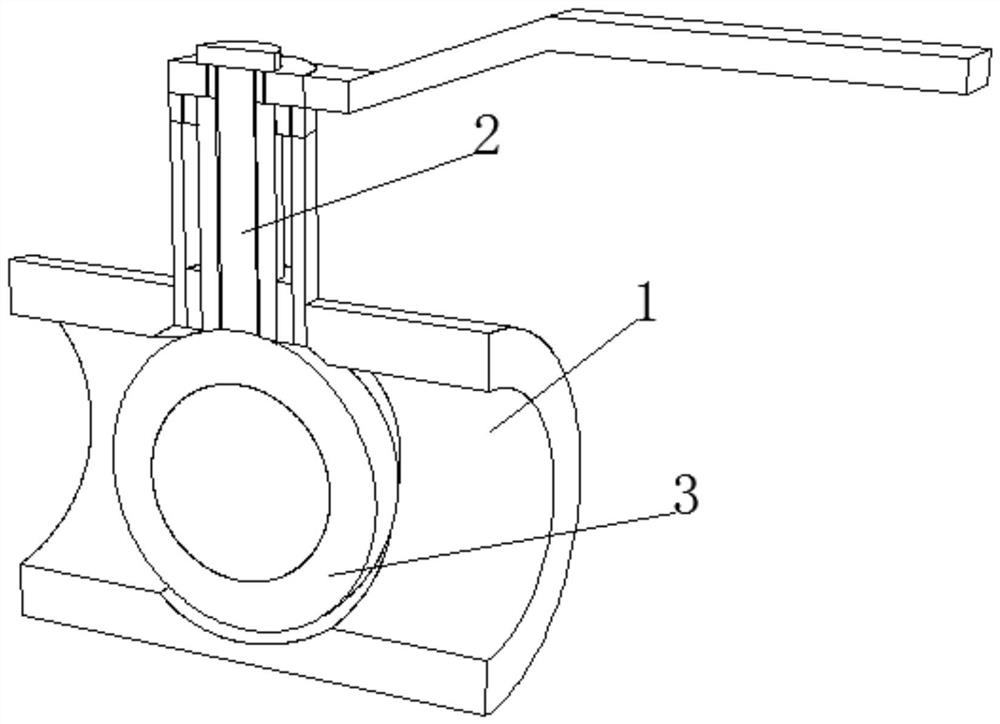

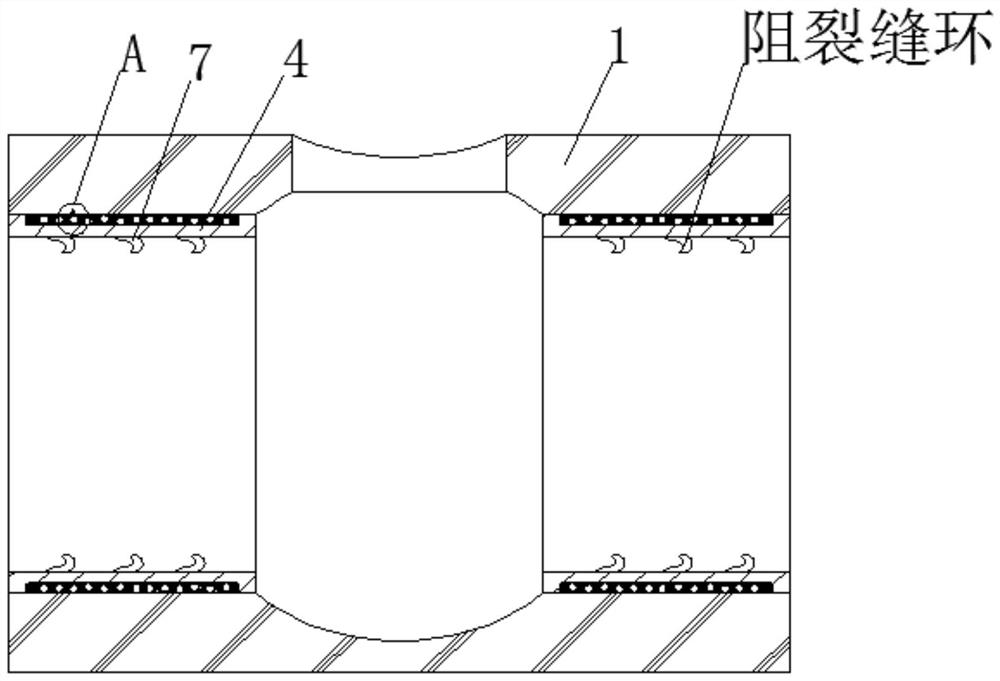

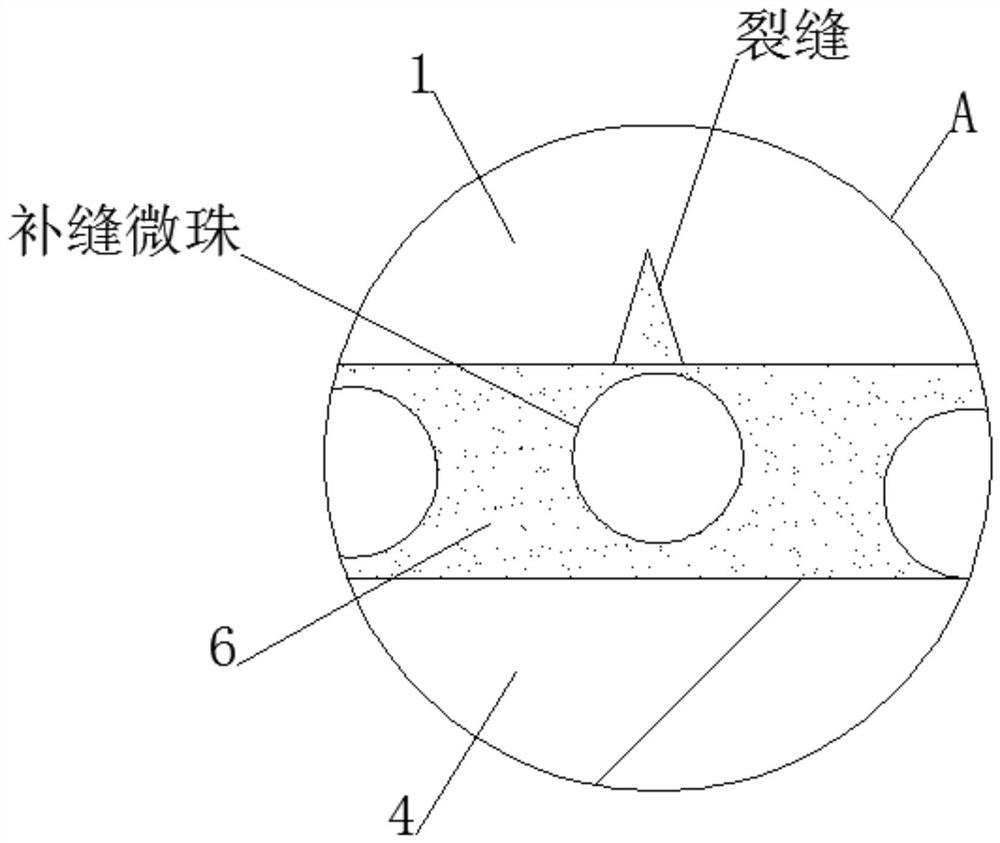

[0044] see figure 1 , including valve body 1, valve stem 2 and valve core 3, the valve core 3 is located in the valve body 1 and matches with the valve body 1, the upper end of the valve core 3 is fixedly connected with the valve stem 2, and the valve stem 2 is sealed and rotated with the valve body 1 connection, see figure 2 , the inner wall of the valve body 1 is provided with a crack-resistant ring, the inner wall of the crack-resistant ring is fixedly connected with a barb body 7, the crack-resistant ring includes an anti-crack ring 4, the crack-resistant ring 4 is bonded to the inner wall of the valve body 1, and the crack-resistant ring 4 is close to the valve One end of the body 1 is fixedly connected with a rigid fluff layer, and the anti-crack ring 4 and the valve body 1 are bonded through the rigid fluff layer. The connection, through the rigid fluff layer, can effectively bond the resistance crack ring to the valve body 1 firmly, and at the same time, it will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com