Drainage pipeline and construction method thereof

A technology for drainage pipes and construction methods, which is applied in the directions of pipe laying and maintenance, non-removable pipe connections, pipes/pipe joints/pipe fittings, etc. Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

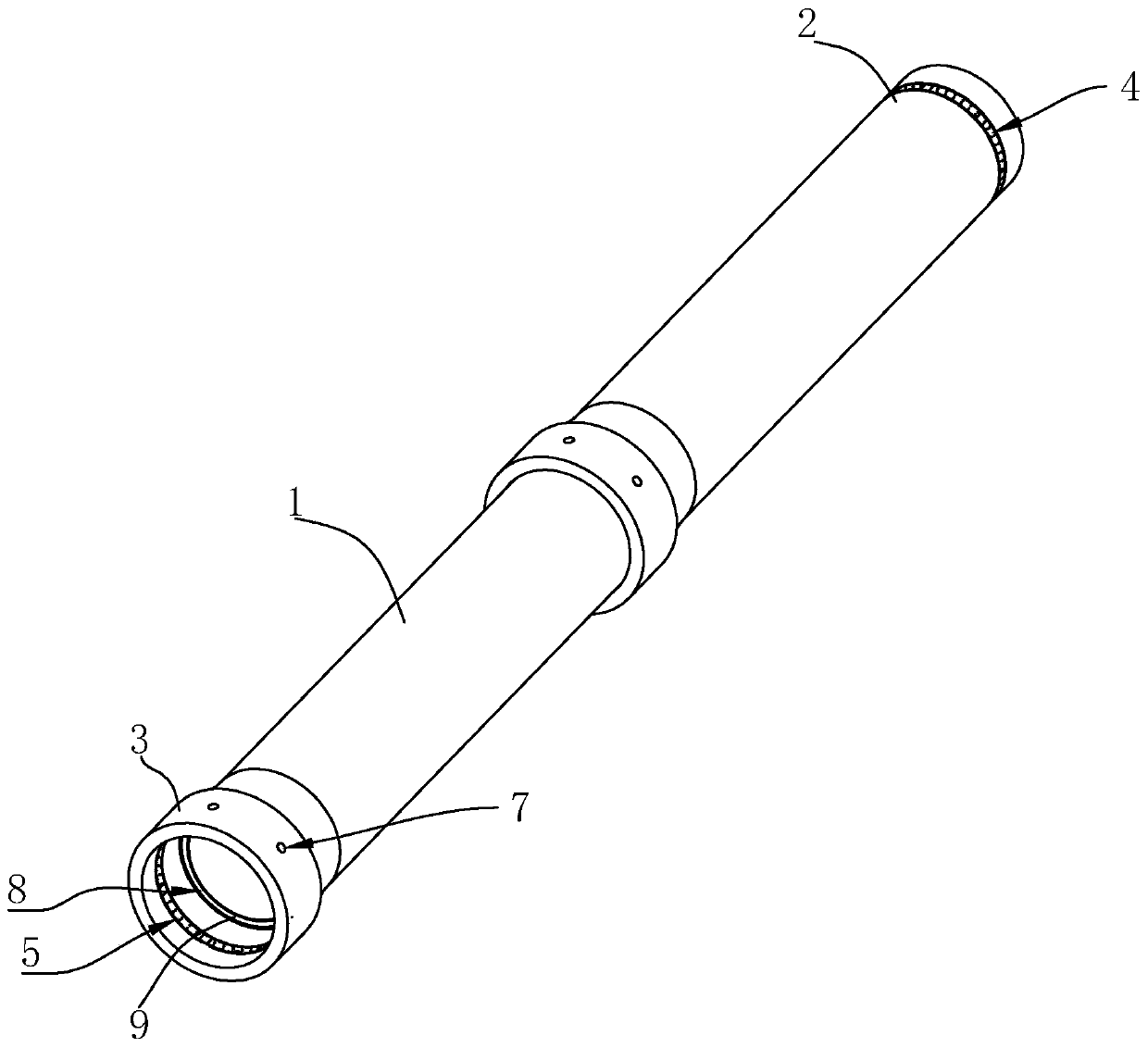

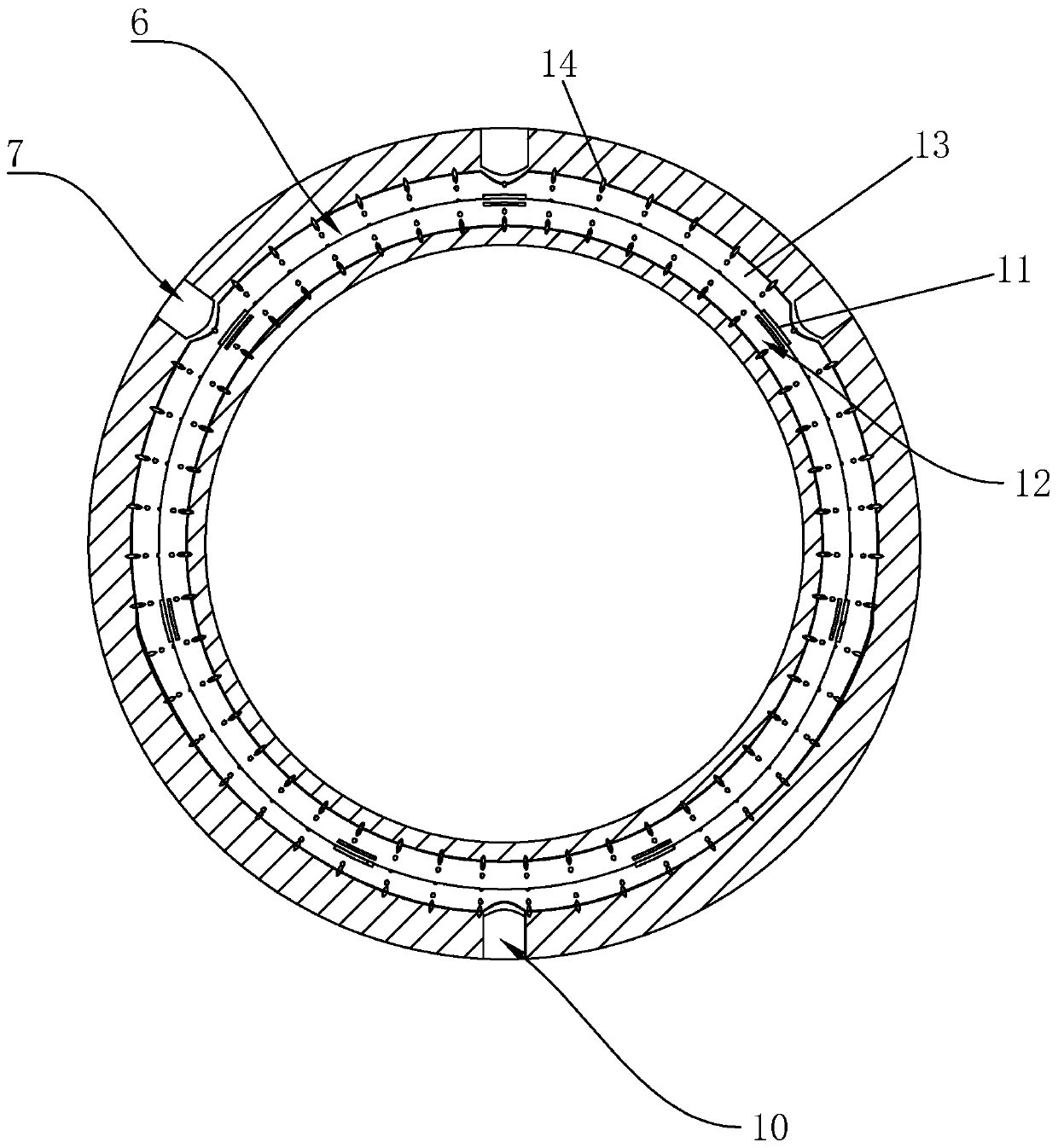

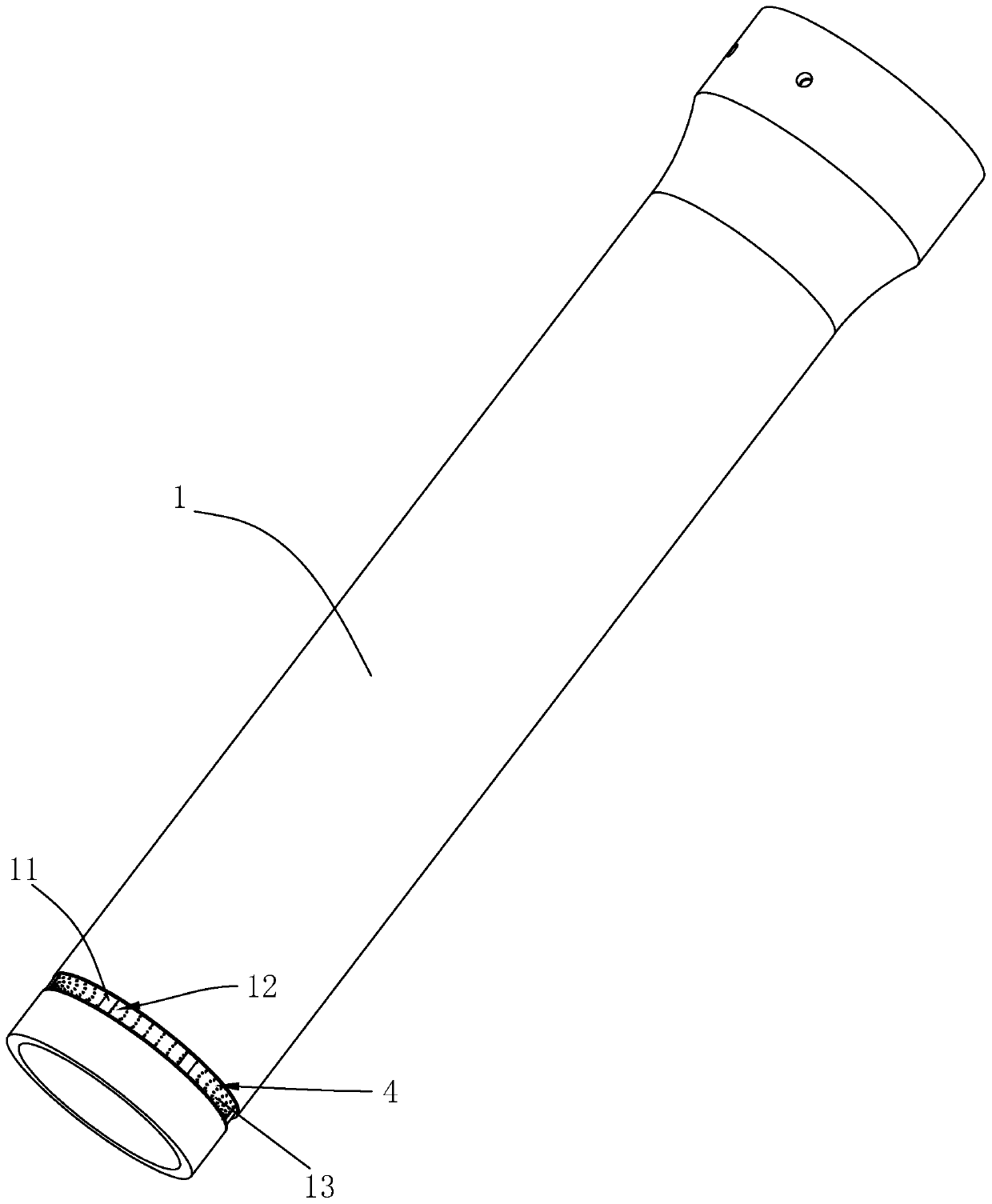

[0045] Such as figure 1 , 2 As shown, a drainage pipe includes a pipe body 1, a socket 2 is provided at one end of the pipe body 1, and a socket 3 is provided at the other end of the pipe body 1, and the socket 3 can be plugged and matched with the socket 2 on the adjacent pipe body 1. , the outer wall of the socket 2 is provided with a first ring groove 4 around the socket 2, and the inner wall of the socket 3 is provided with a second ring groove 5 around the socket 3; when the socket 2 is inserted into the socket 3 of the adjacent pipe body 1, the first ring The groove 4 and the second annular groove 5 just butt each other and form a sealed cavity 6; an inlet 7 is provided on the socket 3, and the inlet 7 communicates the second annular groove 5 with the outer side of the socket 3.

[0046]Among them, the number of inlets 7 is multiple and distributed on the socket 3 along the circumferential direction of the socket 3. At the same time, the socket 3 is provided with an out...

Embodiment 2

[0053] A construction method for a drainage pipeline, comprising the following steps:

[0054] Step 1: Surveying and setting out, organize the surveying team to conduct retesting according to the surveying control points provided by the design institute, establish the engineering surveying control network after the review is correct, carry out the surveying and control of the project combining point and plane, set out the survey, and determine the pipeline centerline and well position, and set the leveling reference point as the control point of the whole project, each measurement must be closed, and the closing error should be strictly controlled;

[0055] Step 2: Trench excavation, determine the soil quality of the excavation area, and select the slope of the slope according to the soil quality, and excavate according to the appropriate slope;

[0056] Step 3: Dewatering in the trench, excavate a drainage ditch on both sides of the bottom of the trench excavated in step 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com