Method for detecting softness of cut tobacco and cut tobacco softness detector

A detection method and softness technology, which is applied in the field of tobacco physical quality detection, can solve the problems that it is difficult to make a representative single shredded tobacco, it is not suitable for the detection of tobacco leaf softness, and the detection and calculation are troublesome, so as to achieve accurate acquisition and easy operation , the effect of accurate response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

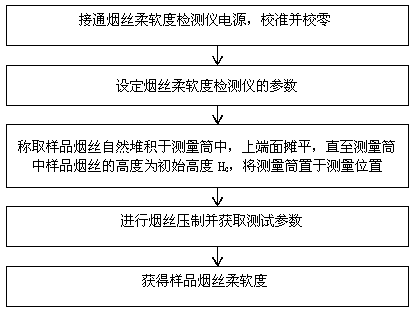

[0030] like figure 1 As shown, the present invention includes a method for detecting softness of shredded tobacco, comprising the following steps:

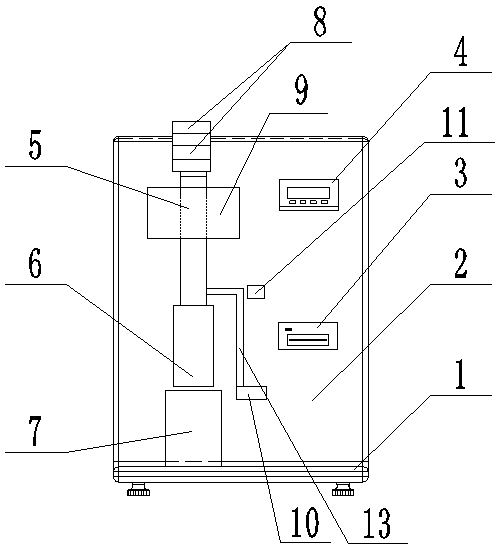

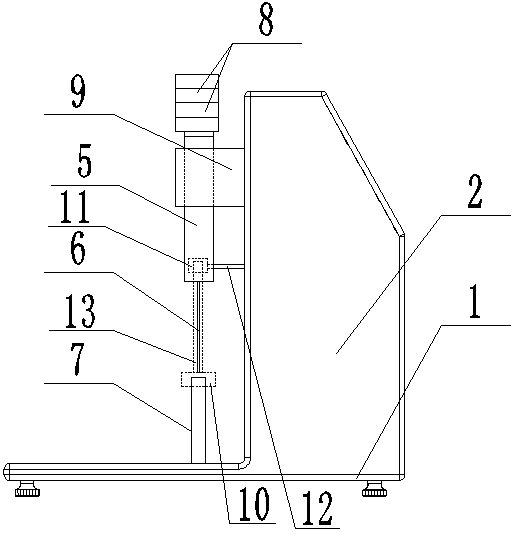

[0031] Step 1: Turn on the power supply of the shredded tobacco softness detector, calibrate and zero; on the pressing mechanism of the shredded tobacco softness detector, an extruding plate 6 is vertically arranged;

[0032] Step 2: Set the parameters of the shredded tobacco softness detector: set the pressing time of the shredded tobacco pressing mechanism as T, the pressing pressure as F, and the initial height of the shredded tobacco sample at the initial moment as H 0 ;

[0033] Step 3: Weigh the sample shredded tobacco, and place the sample shredded tobacco in the measuring cylinder 7 matching the shape of the extrusion plate 6 in a natural accumulation method, and flatten the upper end surface of the sample shredded tobacco until the height of the sample shredded tobacco in the measuring cylinder 7 is initial height H 0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com