Two-step calibration method of light field camera

A technology of light field camera and calibration method, applied in image data processing, instrumentation, calculation, etc., can solve problems such as inability to solve optical parameters, inability to meet usage requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

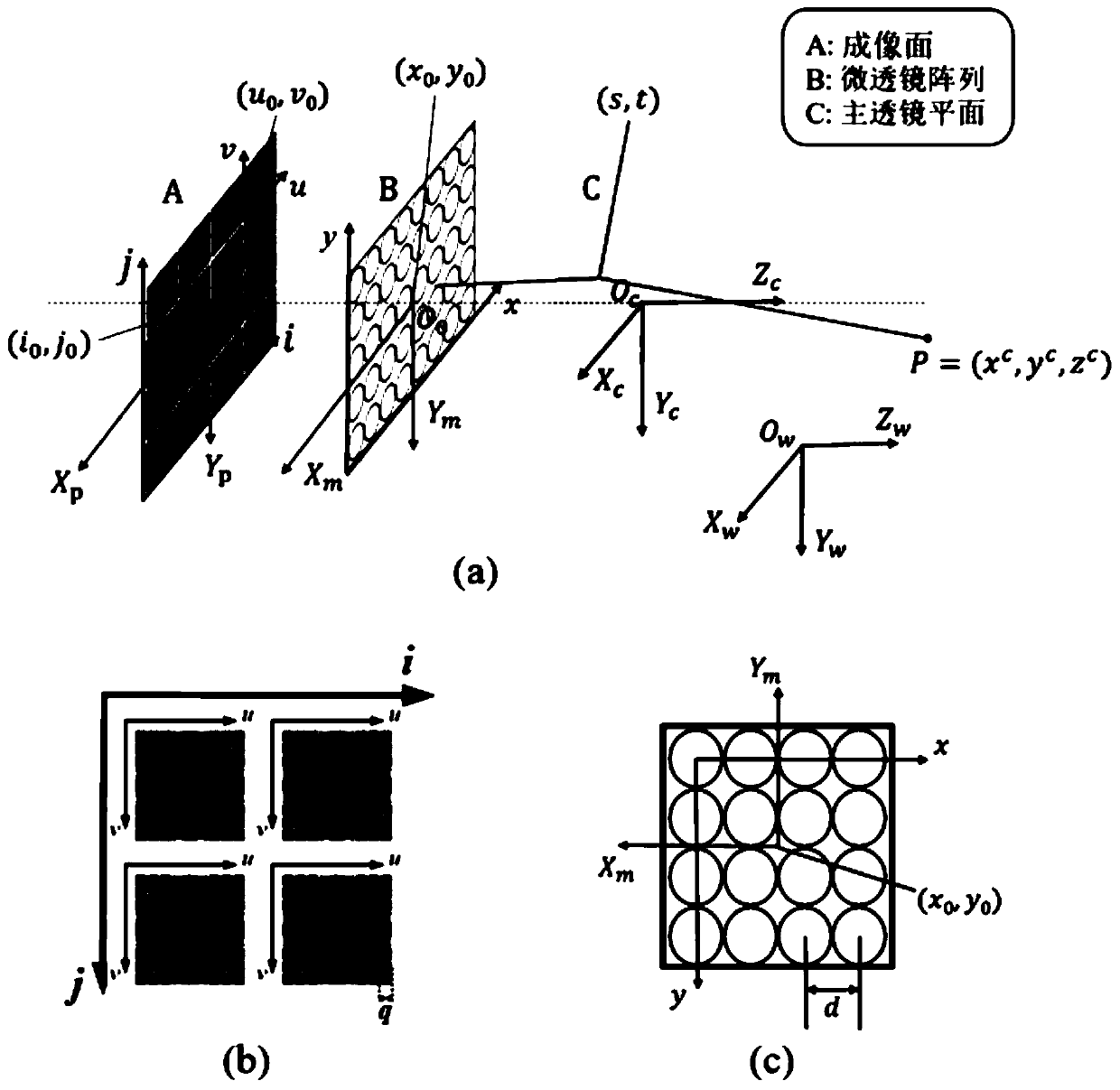

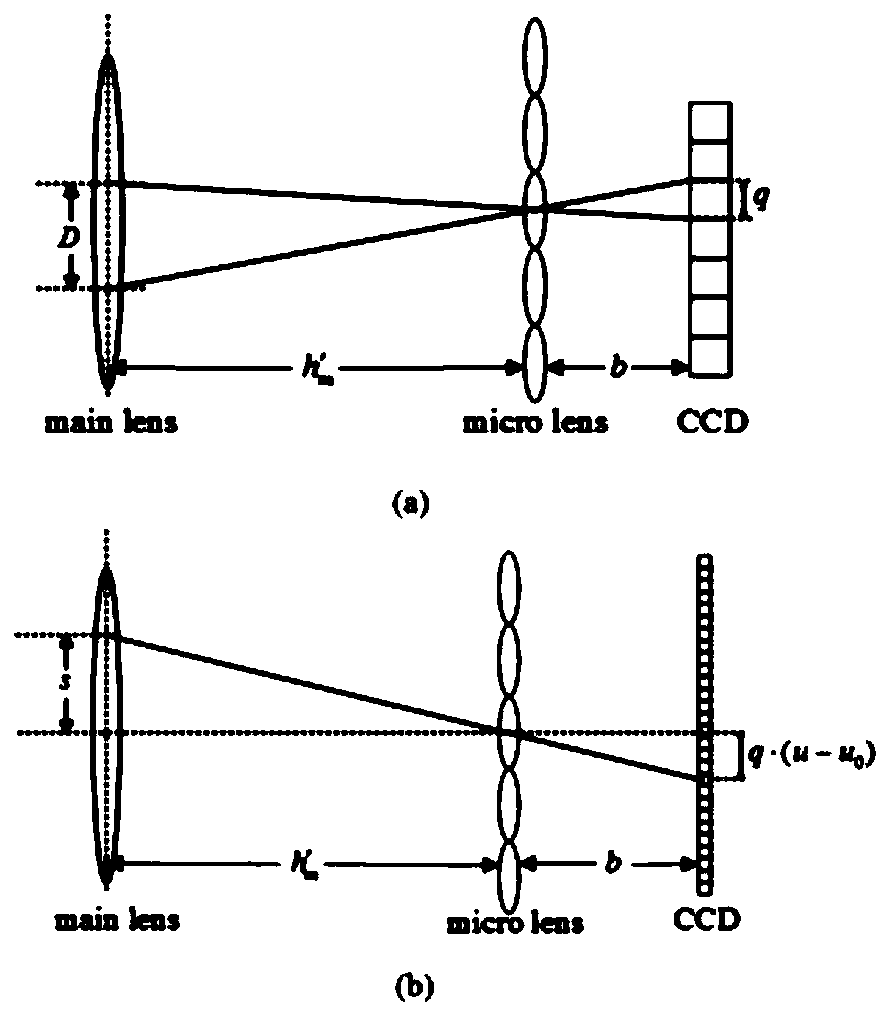

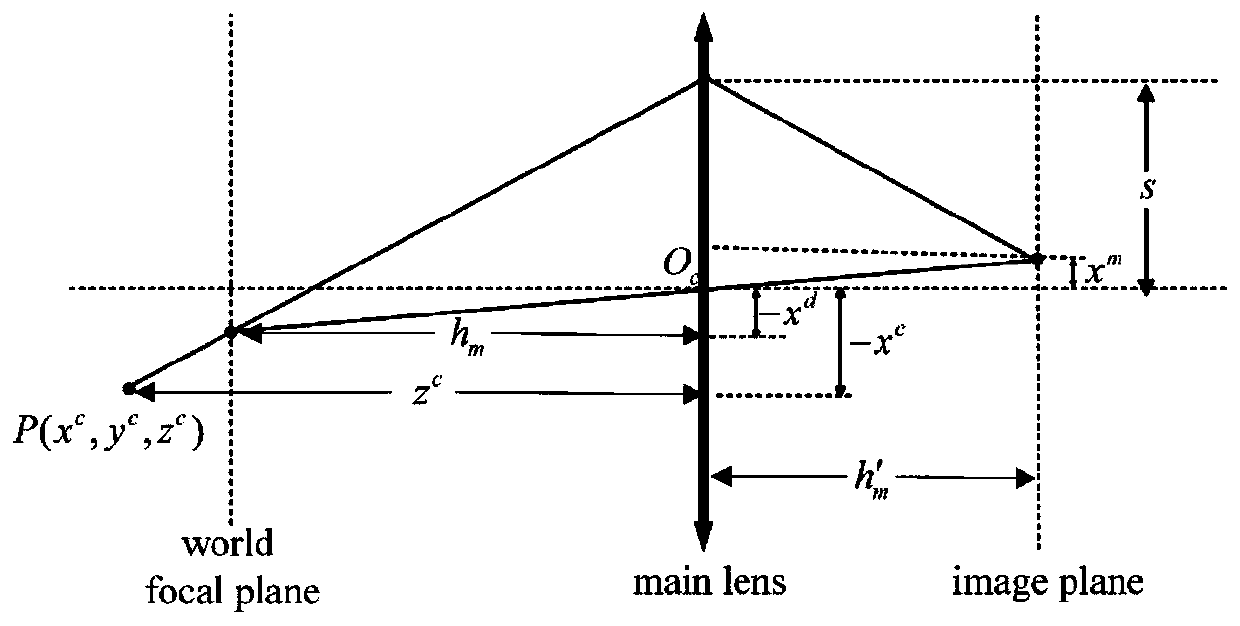

Method used

Image

Examples

Embodiment

[0078] Example: Experiments were carried out with Lytro Illum, a second-generation light field camera produced by Lytro Corporation of the United States. The serial number of the camera is B5152200720. This camera can decode 15×15 sub-aperture images from each light field original image, and each The sub-aperture image resolution is 625×434, the distance between the centers of adjacent microlenses is d=0.01732mm, and the pixel width is q=0.0014mm. A total of 13 angles of calibration plate images are taken. The position optical system between the light field camera and the calibration plate Such as Figure 7 shown. The physical parameters obtained by calibration are shown in the table below:

[0079]

[0080] Figure 8 It is the result of the reprojection error in this embodiment. It can be seen that without nonlinear optimization, the reprojection error is within 0.008mm. After nonlinear optimization, the reprojection error is all within 0.005mm, and most of them are conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com