Ultra-wide-pressure fine water mist spray head

A technology of fine water mist and nozzles, which is applied in fire rescue and other directions, and can solve the problems that the fine water mist nozzles cannot achieve medium and high pressure at the same time, poor atomization effect of nozzles, and system pressure fluctuations, etc., to achieve fire protection and uniform performance Good, the effect of shortening the fire extinguishing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The preferred embodiment of the ultra-wide pressure fine water mist nozzle of the present invention is:

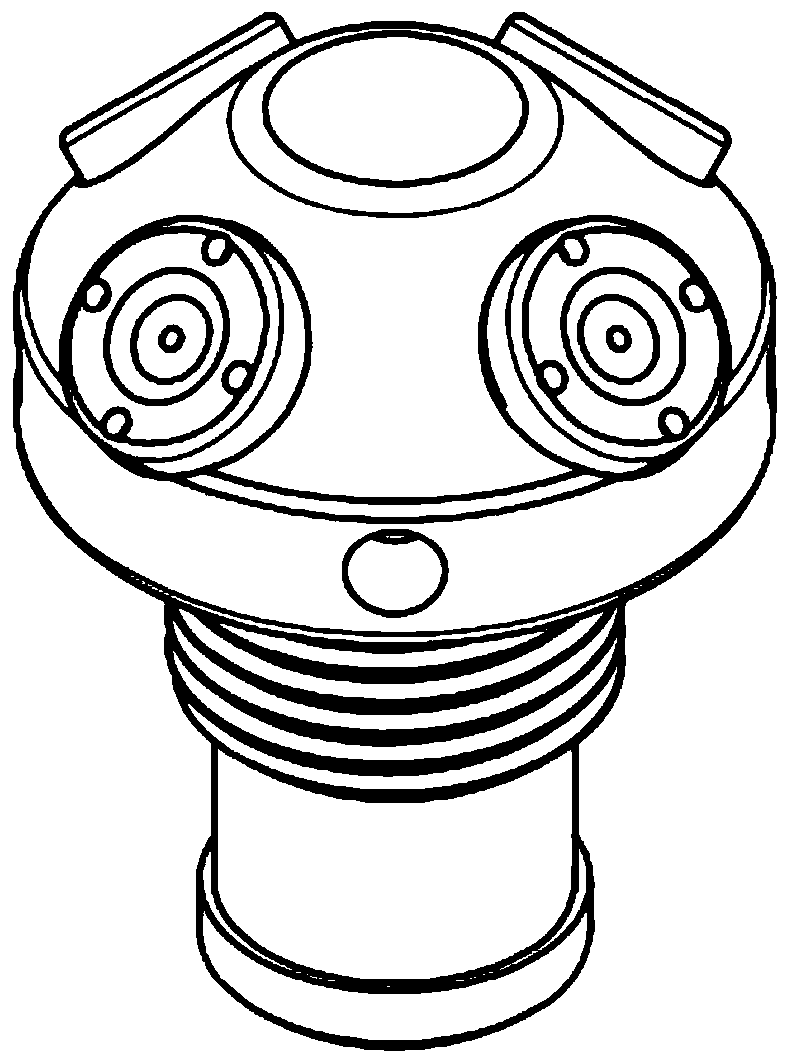

[0023] It includes a nozzle body, the rear end of the nozzle body is provided with a screw plug and a filter screen, the front end of the nozzle body is provided with a conical surface or a spherical surface, and a plurality of nozzles are evenly distributed on the circumference of the conical surface or spherical surface, and each nozzle A vortex device is respectively arranged inside, the nozzle is connected with the nozzle body through an external thread structure, and the rear part of the nozzle body is connected with the existing water supply system through a water supply system connector.

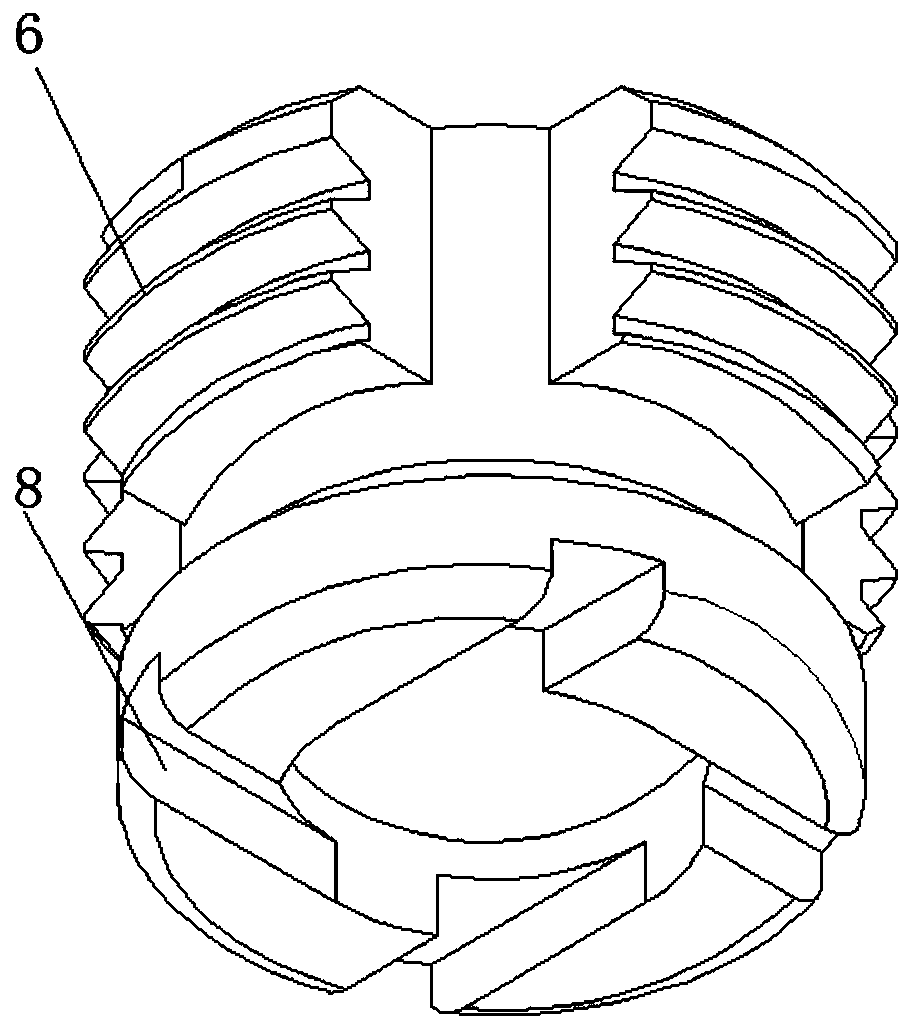

[0024] The side of the vortex is provided with threads and grooved in the axial direction, and is installed in the nozzle by means of the screw thread compression. The front end of the vortex is provided with one or more grooves tangent to the circumference of the vortex cor...

specific Embodiment

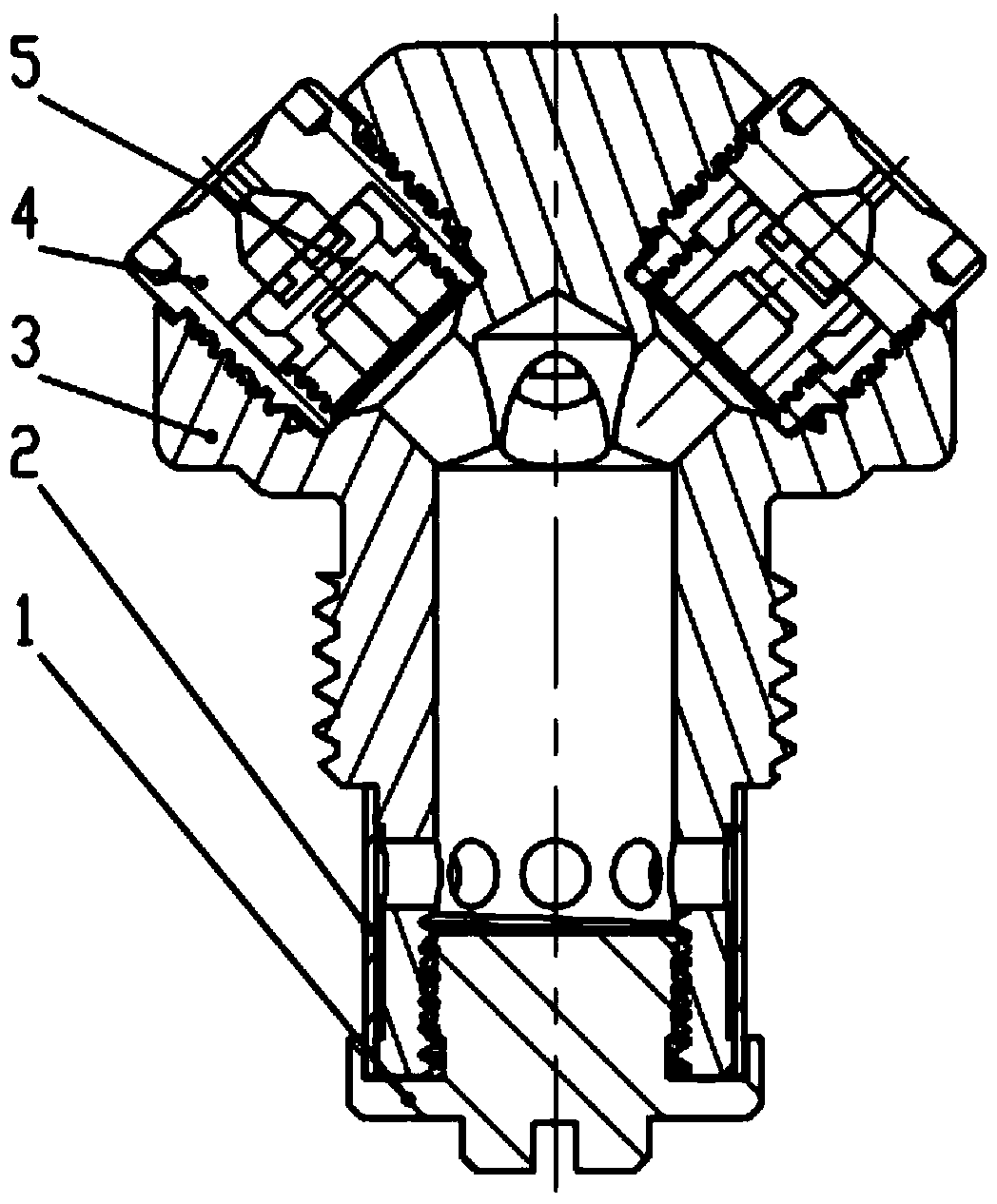

[0036] see figure 1 , The present invention includes a screw plug 1, a filter screen 2, a nozzle body 3, a nozzle 4, and a vortex device 5.

[0037] see figure 2 , the present invention swirl 5 and nozzle 4 fastening thread compression connection schematic diagram.

[0038] see image 3 , a schematic diagram of a vortex device 5 according to the present invention, including a threaded slot 6 and a groove structure 8 .

[0039] see Figure 4 , the nozzle 4 of the present invention controls the water flow rate through the tapered flow channel 7 .

[0040] see Figure 4 , the present invention swirl 5 through the groove 8 and the nozzle 4 fastening thread compression connection schematic diagram.

[0041] see Figure 4 , a schematic diagram of the connection between the nozzle 4 of the present invention and the nozzle body 3 through an external thread structure.

[0042] see Figure 5 , the thread connection diagram of the screw plug 1 of the fastener of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com