Cut pile reinforcement cage welding device

A technology for welding devices and steel bars, which is applied to welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of vertical steel bar tilting and heavy vertical steel bar weight, and achieve convenient welding operations, low manufacturing costs, and improved welding processing. The effect of quality and welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

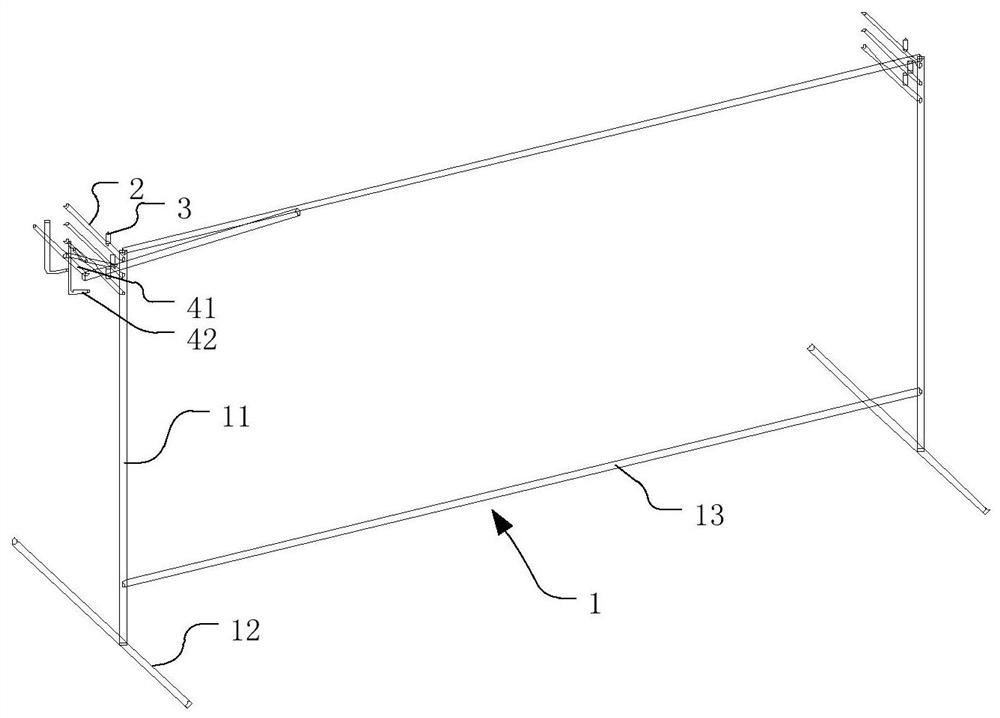

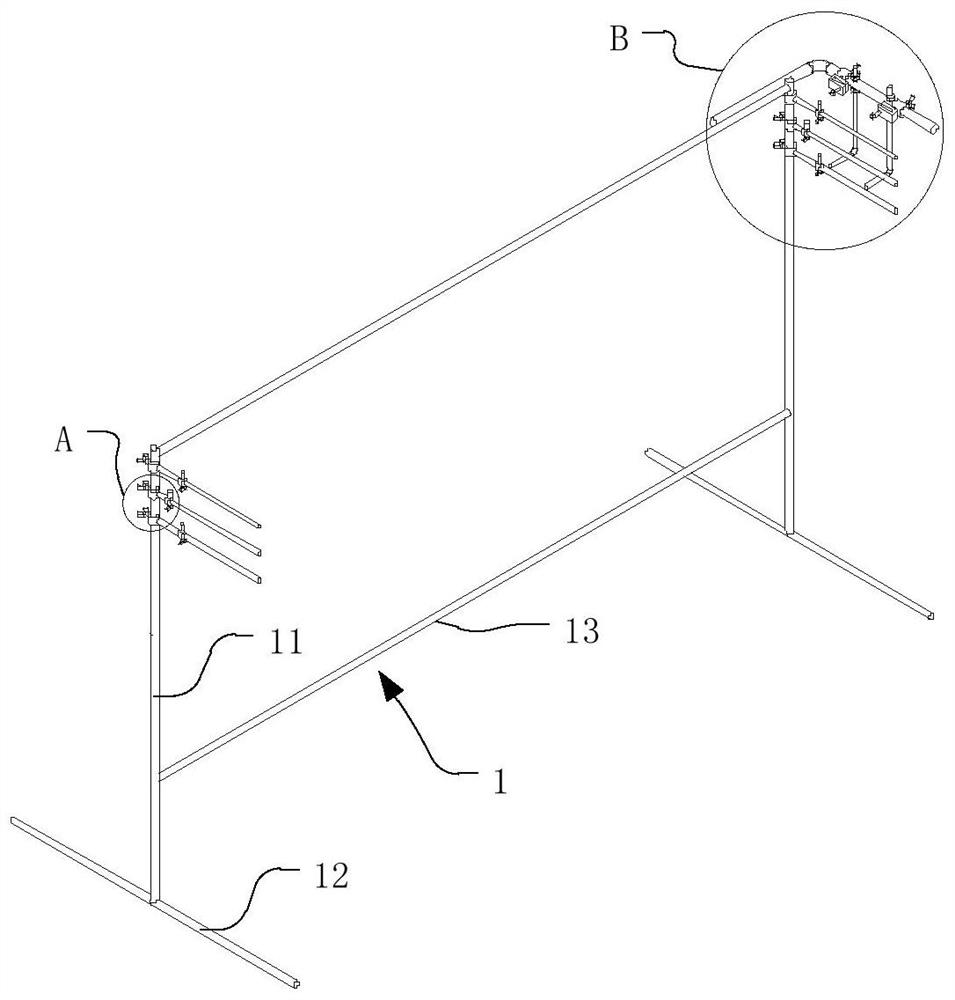

[0025] refer to figure 1 , a pile-cut reinforcement cage welding device is used for welding the pile-cut reinforcement cage. The pile-cut reinforcement cage includes a plurality of vertical reinforcement bars and a supporting plate, and the plurality of vertical reinforcement bars are vertically welded on the supporting plate. This embodiment takes a pile-cut reinforcement cage with 6 vertical steel bars as an example, and describes the welding device applicable to this kind of pile-cut reinforcement cage. The welding device for pile-cut reinforcement cage in this embodiment includes a bracket 1 , and a first horizontal positioning rod group, a second horizontal positioning rod group and a pallet frame arranged on the bracket 1 . The support 1 includes a support frame and a cross bar 13. The number of the support frames is two. The two support frames are arranged in parallel at a preset distance and connected through the cross bar 13. Each support frame includes a horizontal l...

Embodiment 2

[0030] The structure of this embodiment is the same as that of the bracket 1 of the first embodiment, and the difference from the first embodiment is that the heights of the multiple horizontal positioning rods 2 of the first horizontal positioning rod group and the second horizontal positioning rod group are movable and adjustable. On the support 1, the positioning column 3 is set on the horizontal positioning rod 2 in a movable and adjustable manner, and the height of the pallet frame is set on the support 1 in a movable and adjustable manner.

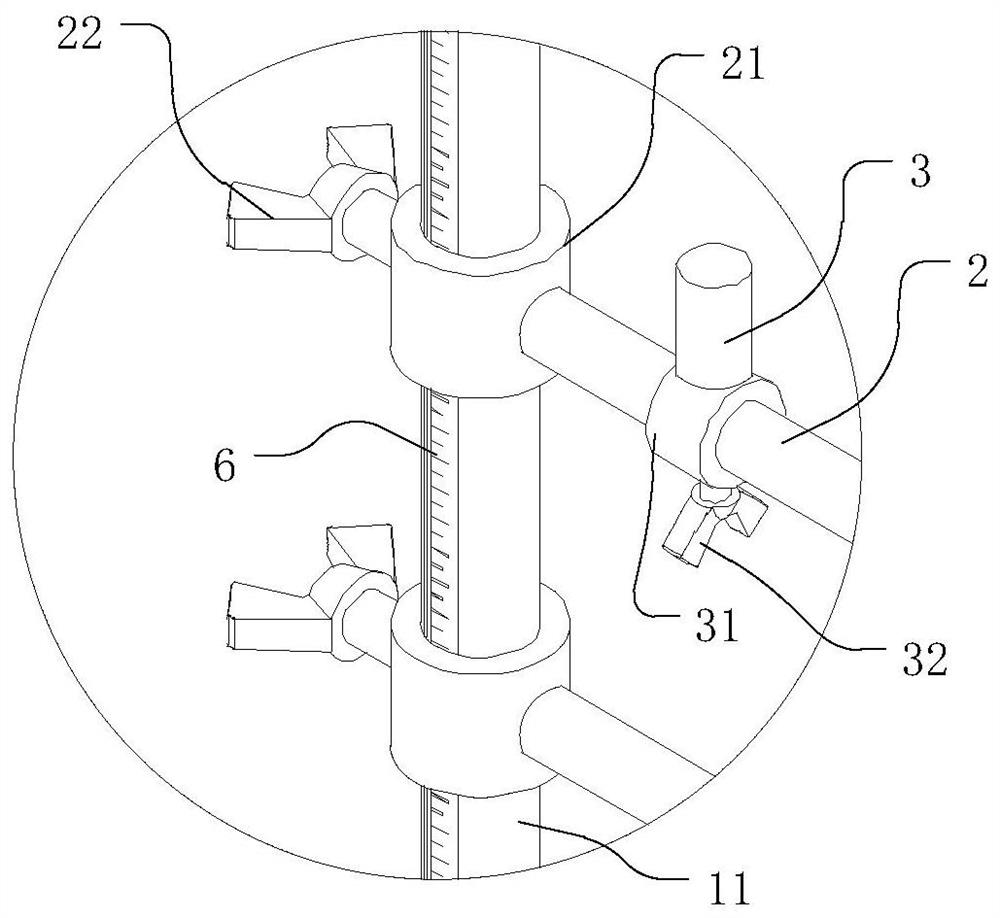

[0031] refer to Figure 2-5, the present embodiment also takes a pile-cut reinforcement cage with 6 vertical steel bars 71 as an example, and describes the welding device applicable to this kind of pile-cut reinforcement cage. Three horizontal positioning rods 2 are arranged on the upper end of each vertical rod 11 respectively, and the heights of the three horizontal positioning rods 2 on the vertical rod 11 can be adjusted. Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com