Sand aggregate bucket elevator hopper control system and control method

A bucket elevator and control system technology, which is applied in the direction of conveyor control devices, conveyor objects, cleaning devices, etc., can solve the problems of reducing production line operation efficiency and hopper damage, so as to reduce maintenance costs and man-hours, and protect The effect of being worn and improving the operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

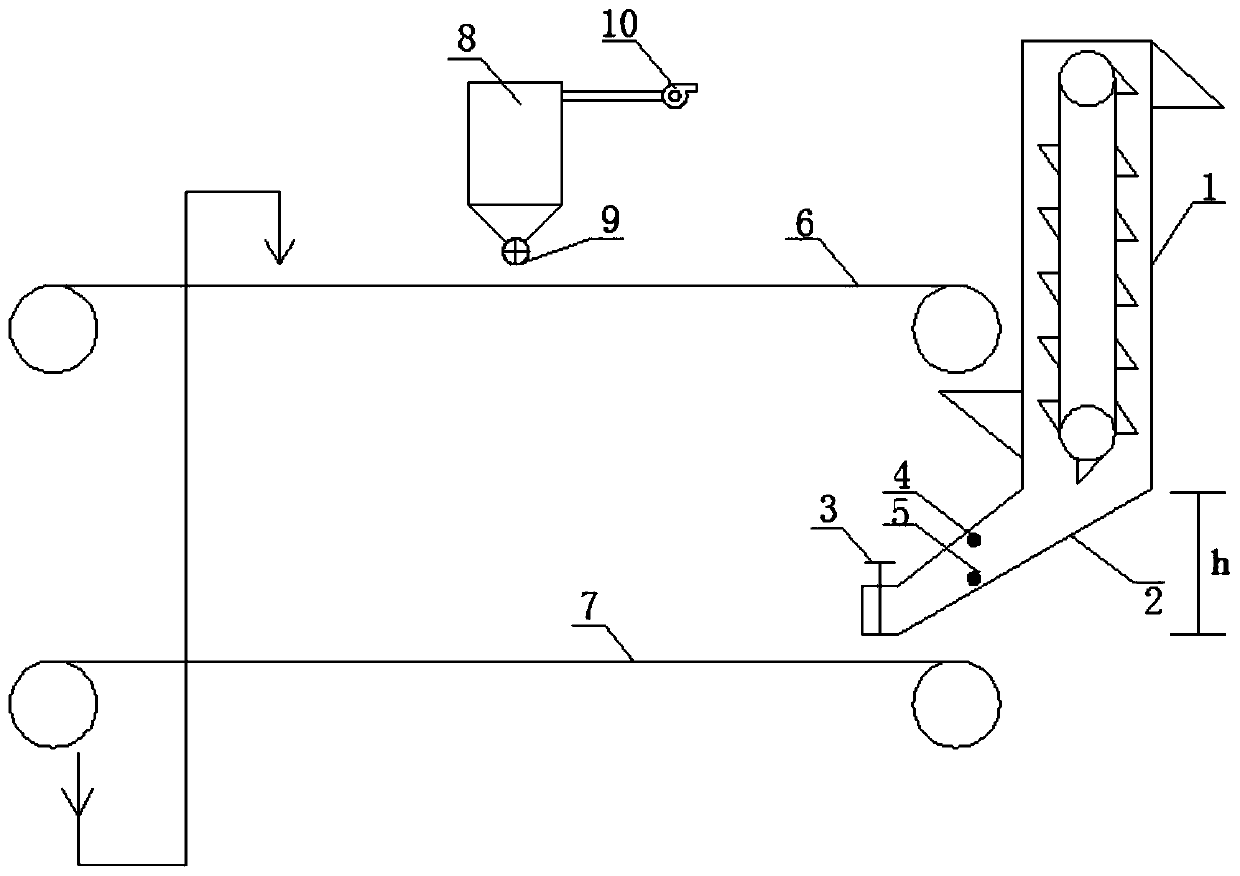

[0017] Specific embodiment 1: The hopper control system of the gravel aggregate bucket elevator in this embodiment is composed of a bucket elevator 1, a collecting hopper 2, a feeding belt conveyor 6, a return belt conveyor 7 and a PLC controller;

[0018] The collecting hopper 2 is elongated and cylindrical, and the collecting hopper 2 is arranged obliquely. At the discharge port, the discharge port of the collecting hopper 2 is provided with an electric gate valve 3; the collecting hopper 2 is provided with a first material level gauge 4 and a second material level gauge 5, and the first material level gauge 4 is set on the second material level gauge. above the bit meter 5;

[0019] The feed end of described return material belt conveyor 7 is arranged below the discharge opening of collecting hopper 2, and the discharge end of return material belt conveyor 7 is arranged above the feed end of feed belt conveyor 6, and the feed belt The discharge end of the conveyor 6 is arr...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the control signal input end of the drive motor of the described feeding belt conveyor 6 is connected with the control signal output end of the PLC controller through a signal line; The control signal input end of the valve 3 is connected with the control signal output end of the PLC controller through a signal line; the control signal input end of the driving motor of the return belt conveyor 7 is connected with the control signal output end of the PLC controller through a signal line; The signal output terminals of the first material level gauge 4 and the second material level gauge 5 are respectively connected with the control signal input terminals of the PLC controller through signal lines. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the hopper control system of the gravel aggregate bucket elevator is provided with a bag dust collector 8, and the outlet of the bottom of the bag dust collector 8 is A star-shaped ash unloading valve 9 is provided, and the discharge port at the bottom of the bag dust collector 8 is set facing the feeding belt conveyor 6; a centrifugal fan 10 is connected to the exhaust pipe of the bag dust collector 8, and the bag dust collector 8 is provided with Multiple air inlets, the air inlets of the bag filter 8 are respectively set above the feeding end of the return belt conveyor 7, above the feeding end of the feeding belt conveyor 6 and at the feeding port of the bucket elevator 1 above. Other steps and parameters are the same as those in Embodiment 1 or 2. The function of the air inlet of the bag dust collector 8 is to collect dust, and the mixture of dust and air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com