Preparation method of air injection consolidation antibacterial nonwoven fabric and antibacterial nonwoven fabric

A non-woven fabric and knot-type technology, which is applied in the direction of non-woven fabrics, textiles, and papermaking, can solve the problems of poor uniform dispersion, easy leakage, and poor comfort, and achieve strong deodorization, increased comfort, and compactness strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

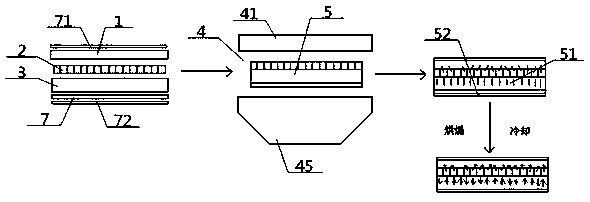

[0032] See Figure 1 to Figure 4 , A method for preparing an air-jet consolidated antibacterial nonwoven fabric, including the following steps:

[0033] Fiber web preparation steps: respectively prepare the upper covering fiber web 71, the upper elastic fiber web 1, the bamboo raw fiber web 2, the lower elastic fiber web 3, the dense fiber web 7, and the lower covering fiber web 72. The upper elastic fiber The raw materials of the net 1, the lower elastic fiber net 3 include chemical fibers and hot-melt short fibers, and the content of chemical fibers is greater than the hot-melt short fibers, and the raw bamboo fiber net 2 is made of raw bamboo fibers;

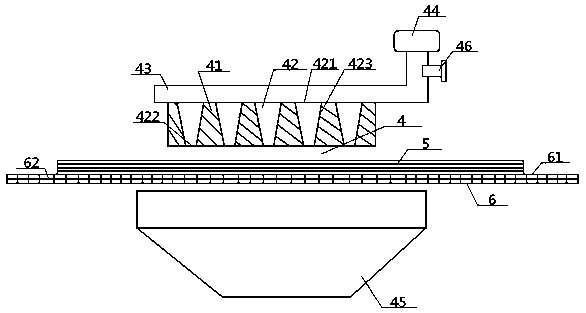

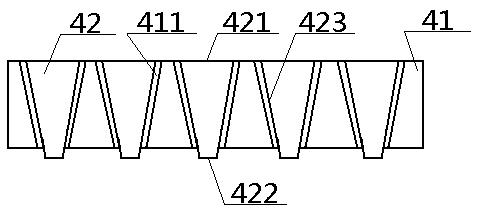

[0034] Air jet consolidation step: first connect the jet hole 42 in the jet plate 41 to the air source 44 through the air inlet pipe 43, and then an air suction box 45 is arranged directly below the jet plate 41. At this time, the jet plate 41, The area sandwiched between the air boxes 45 is the air jet area 4. Then the bottom su...

Embodiment 1

[0056] See Figure 1 to Figure 4 , A method for preparing an air-jet consolidated antibacterial nonwoven fabric, including the following steps:

[0057] The fiber web preparation steps: respectively prepare the upper covering fiber web 71, the upper elastic fiber web 1, the bamboo raw fiber web 2, the lower elastic fiber web 3, the dense fiber web 7, and the lower covering fiber web 72 (preferably the upper elastic fiber web The thickness of the fiber web 1 is less than or equal to the thickness of the lower elastic fiber web 3), the upper elastic fiber web 1 and the lower elastic fiber web 3 are made of chemical fibers and hot melt short fibers, and the content of chemical fibers is greater than that of hot melt Short fibers, the raw bamboo fiber net 2 is made of raw bamboo fibers;

[0058] Air jet consolidation step: first connect the jet hole 42 in the jet plate 41 to the air source 44 through the air inlet pipe 43, and then an air suction box 45 is arranged directly below the ...

Embodiment 2

[0062] The basic content is the same as Example 1, the difference is:

[0063] The bamboo raw fiber net 2 includes a plurality of inclined bamboo raw fibers 22 in a position near the upper elastic fiber net 1; the bottom ends of the inclined bamboo raw fibers 22 are located in the bamboo raw fiber net 2, and the top ends of the inclined bamboo raw fibers 22 are inserted with elastic fibers Inside the net 1, and the top end of the slanted raw bamboo fiber 22 is fused with the chemical fibers and hot melt short fibers in the upper elastic fiber net 1 located on the periphery thereof to form an integrated structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com