A kind of anti-bending structure of body-in-white and its arrangement method

A body-in-white and anti-bending technology, which is applied to load-bearing body structures, superstructures, superstructure subassemblies, etc., can solve the problem of poor bending resistance, poor bearing capacity and bending resistance, and water tank bracket assembly. Self-weight and other problems, to achieve good bending effect, high bending resistance, and increase the effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification. The front, rear, left, and right orientations involved in the present invention all take the body in white as a reference, and the normal driving direction is the front.

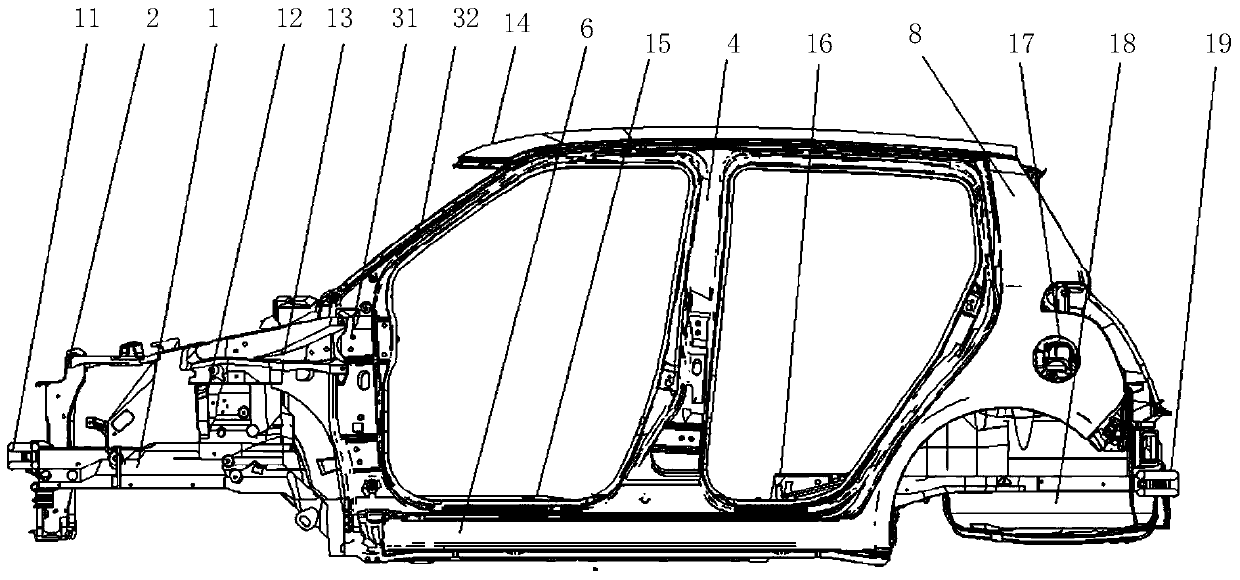

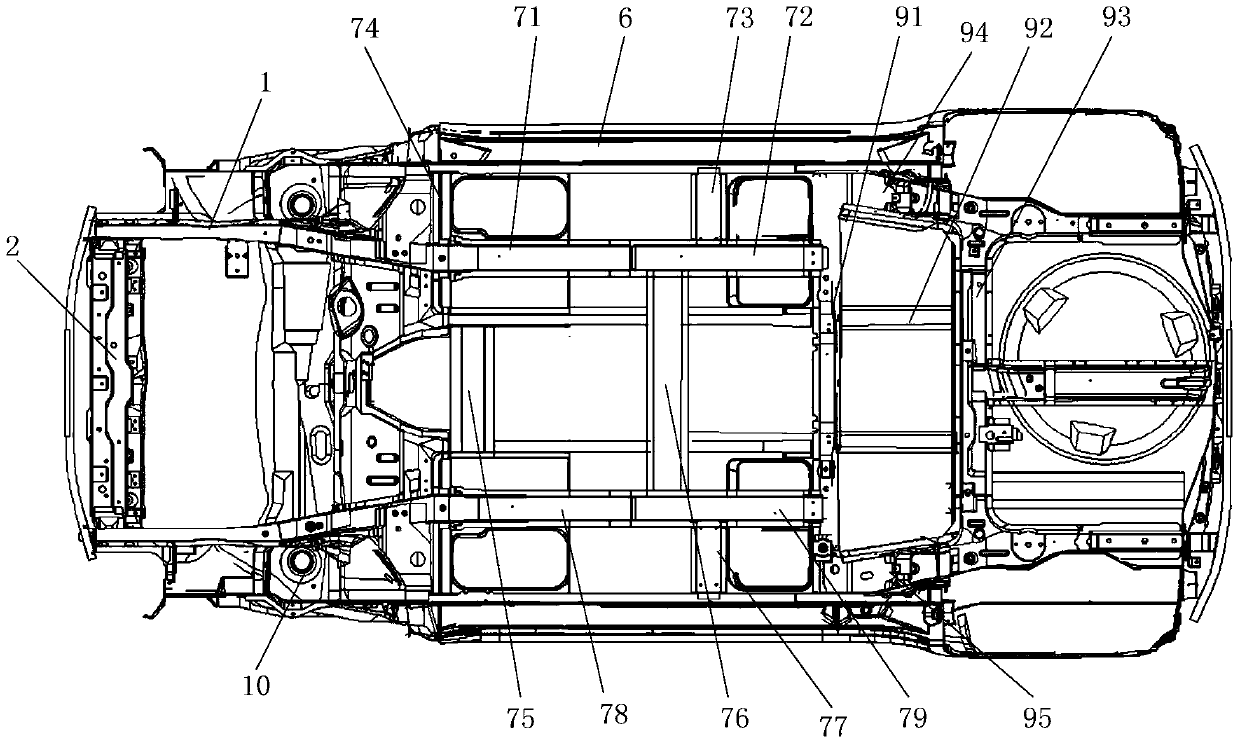

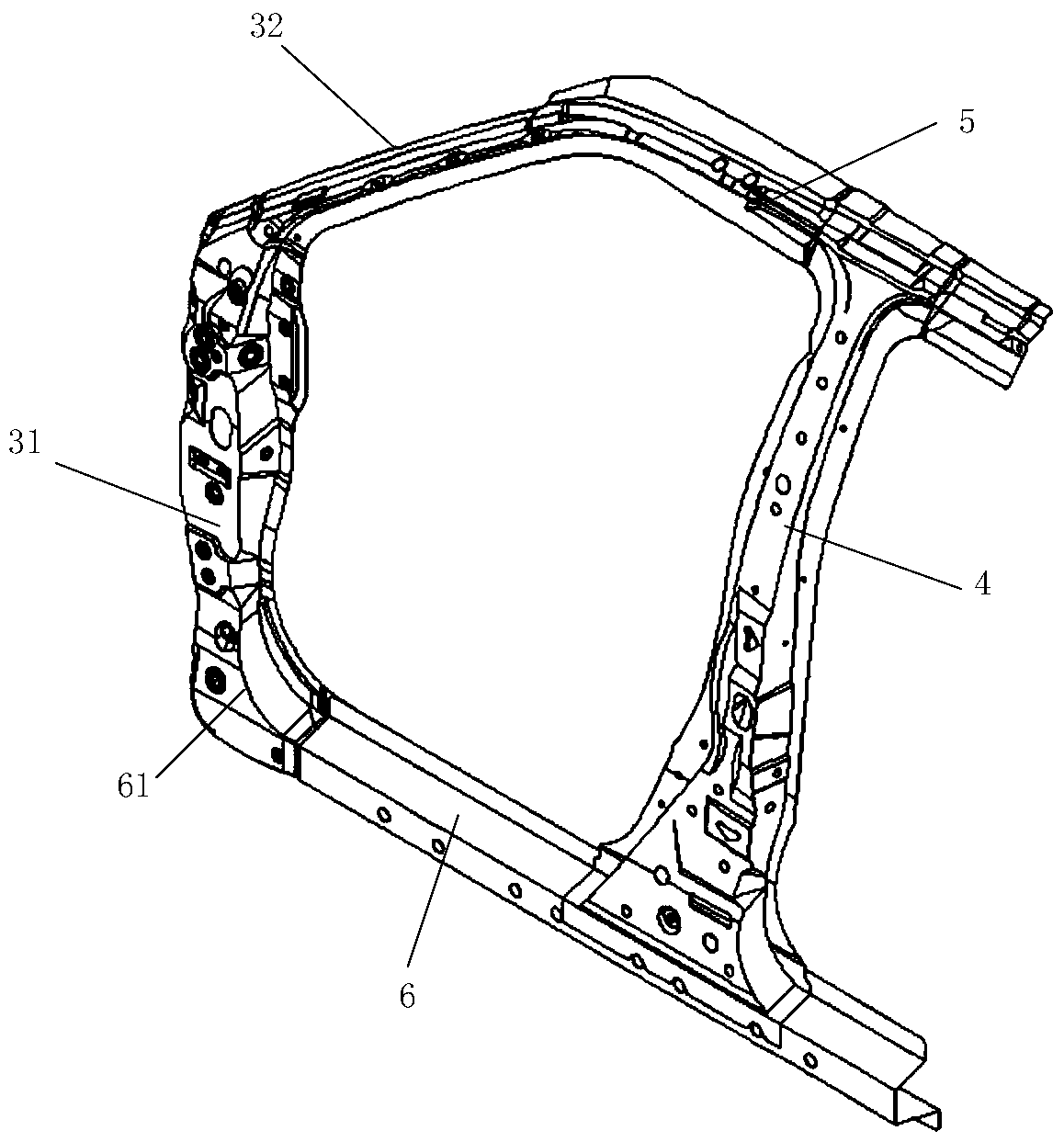

[0065] The present invention provides a body-in-white anti-bending structure. In the embodiment of the present invention, the following body-in-white is taken as an example for structural description. The structure of the body-in-white is as follows: figure 1 and figure 2 As shown, its main structure and its assembly are composed of the following parts: front bumper 11, water tank bracket assembly 1, front longitudinal beam 2, engine suspension mounting bracket assembly 12, dash panel 13, A-pillar assembly Cheng 3, B-pillar assembly 4, B-pillar up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com