Fabric dyeing and finishing process for preventing color shading of side and center

A process, dyeing and finishing technology, applied in the field of textile fabrics, can solve the problems of uneven distribution, different permeability of the fabric surface, and color difference in the edge of the fabric, so as to achieve uniform permeability, pure and full color, and simplify the process of the problem of edge difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

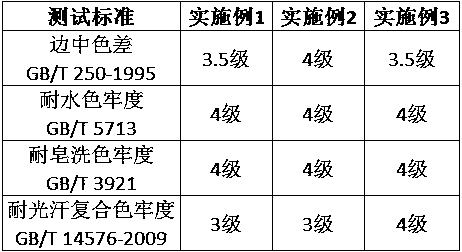

Examples

Embodiment 1

[0025] A kind of fabric dyeing and finishing technology that prevents the difference in edge, comprises the following steps:

[0026] S1: Pre-type. Control the difference in moisture content between the left, middle, right and front, middle and back of the gray cloth to 2.5% before pre-setting. The first stage, width preservation, setting time is 5s, the setting temperature of the first part is 160°C, and the setting temperature of the second part is 185°C; the second stage, progressive stretching, the width stretching rate is 3.5%, and the setting time is 4s, the setting temperature is 195°C; the third stage, width preservation, the setting time is 3s, the setting temperature is 195°C; the fourth stage, progressive narrowing, the width shrinkage rate is 2%, the setting time is 3s, the setting temperature 195°C; the fifth stage, width preservation, setting time is 3s, setting temperature is 180°C;

[0027] Obviously, this embodiment may also include a subsequent dyeing proce...

Embodiment 2

[0029] A kind of fabric dyeing and finishing technology that prevents the difference in edge, comprises the following steps:

[0030] S1: Gray fabric pretreatment. After unwinding, cold stacking, and open-width washing, keep the moisture content difference between the left, middle, right and front, middle, and back of the cloth surface at 2.5%;

[0031] S2: Pre-type. The first stage, width preservation, the setting time is 10s, the setting temperature of the first part is 150°C, and the setting temperature of the second part is 180°C; the second stage, progressive tentering, the width stretching rate is 3%, and the setting time is 8s, the setting temperature is 190°C; the third stage, width preservation, the setting time is 5s, the setting temperature is 190°C; the fourth stage, progressive narrowing, the width shrinkage rate is 2%, the setting time is 5s, the setting temperature 190°C; the fifth stage, width preservation, setting time is 5s, setting temperature is 170°C;

...

Embodiment 3

[0035] A kind of fabric dyeing and finishing technology that prevents the difference in edge, comprises the following steps:

[0036] S1: Gray fabric pretreatment. After unwinding, cold stacking, and open-width washing, keep the moisture content difference between the left, middle, right and front, middle, and back of the cloth surface at 2.5%;

[0037] S2: Pre-type. The first stage, width preservation, the setting time is 3s, the setting temperature of the first part is 170°C, and the setting temperature of the second part is 200°C; the second stage, progressive stretching, the width stretching rate is 4%, and the setting time is 3s, setting temperature is 200°C; the third stage, width preservation, setting time is 2s, setting temperature is 200°C; fourth stage, progressive narrowing, width shrinkage rate is 2%, setting time is 2s, setting temperature 200°C; the fifth stage, width preservation, setting time is 2s, setting temperature is 170°C;

[0038] S3: Staining. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com