Roof construction method of broken bridge waterproof roof gutter spout funnel

A construction method and the technology of sinking bucket, which are applied in the direction of roof, roof covering, roof drainage, etc., can solve the problem of not considering the closed combination of flat coil and fan-shaped coil at the sink, shortening the service life of the building, affecting the use function, etc. The problem is to avoid the roof seepage, increase the stroke, and slow down the speed of leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

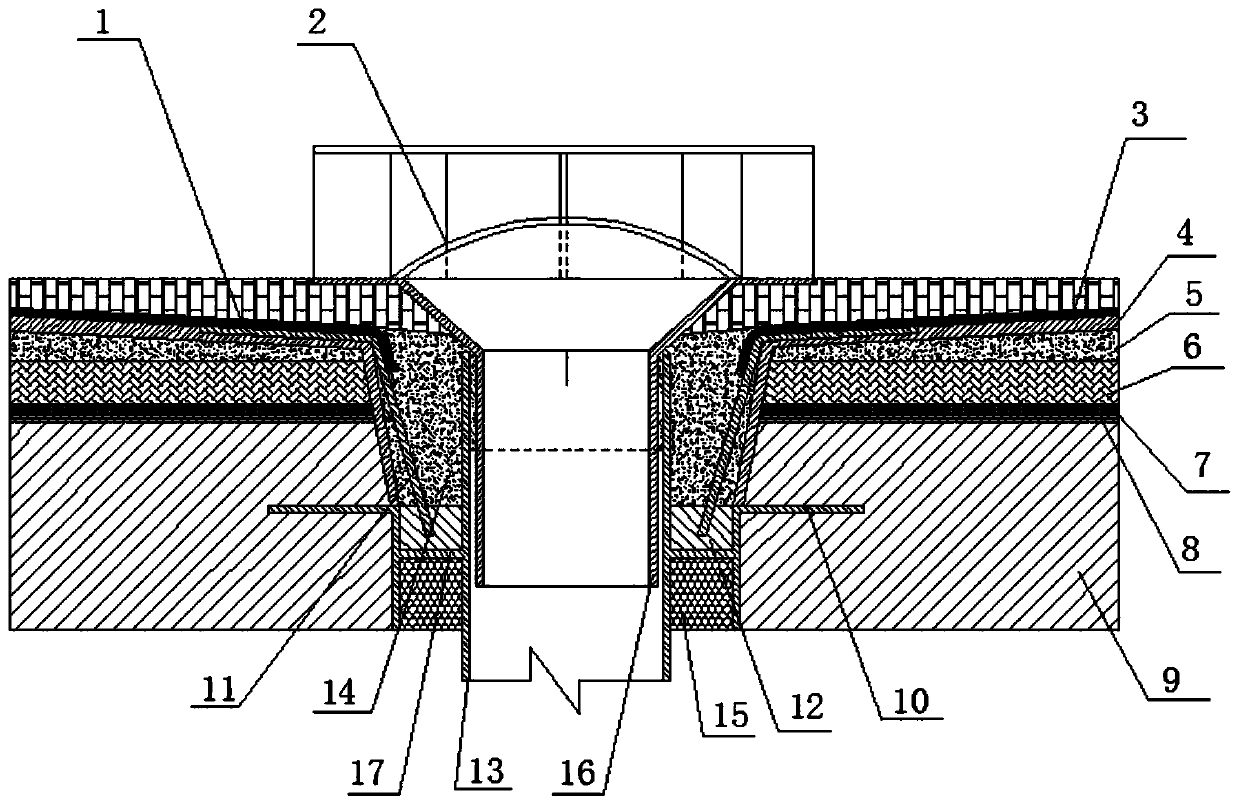

[0022] refer to figure 1 The embodiment of the roof construction method of a broken bridge waterproof roof gutter of the present invention will be further described.

[0023] A roof construction method for the water-repellent roof of a broken bridge. A concrete layer 9 is laid on the roof. Generally, the thickness of the concrete is about 120mm. The ring 10 is pre-embedded in the concrete layer 9; it is poured together with the concrete layer 9. After the strength of the concrete layer 9 is qualified, the first leveling layer 8 is laid on the concrete layer 9. Generally, the thickness of the first leveling layer 8 is 20mm. Left and right, because the surface of the concrete layer 9 is pitted, it is necessary to lay the first leveling layer 8 to make the surface smooth for subsequent construction. After the first leveling layer 8, lay a vapor barrier layer 7 of about 10mm and a heat insulation layer of about 80mm 6. The purpose is to avoid the problem of water seepage in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com