Surface adjustable air pulse crushing device and construction method for tunnel fluid filling lining

A crushing device and fluid technology, applied in the direction of tunnel lining, tunnel, filling, etc., can solve the problems of high pressure of secondary lining steel arch and difficulty in crushing fluid filling, and achieve the effect of ensuring normal operation and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

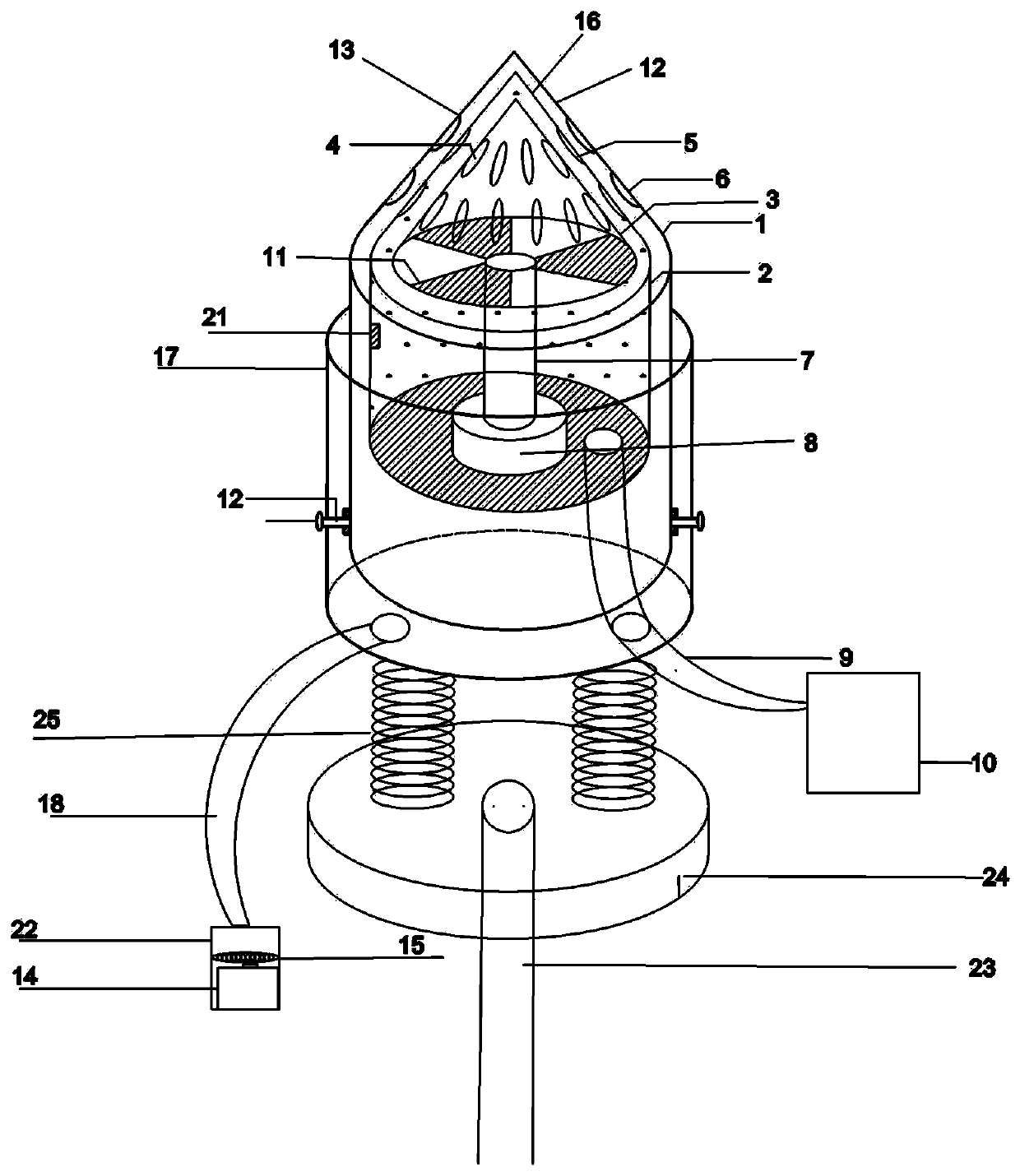

[0029] like figure 1 and figure 2 As shown, a surface-type adjustable air pulse crushing device for tunnel fluid filling lining includes a spring support 24 with a reaction rod 23, one end of a plurality of supporting springs 25 is arranged on the top surface of the spring support 24, and a plurality of spring supports 25 are provided. The other end of the support spring 25 is connected to the bottom of the outer casing 17 whose top surface is open, and is characterized in that:

[0030] The bottomless metal casing 1 with the first wedge-shaped head 13 is placed in the outer casing 17 and hinged with the inner wall of the outer casing 17, and the bottomless metal casing 1 is provided with a second wedge-shaped head 16. The air chamber 2, the inner bottom surface of the air storage chamber 2 is provided with a rotary motor 8, and the output shaft of the rotary motor 8 is connected with the connecting truss 11 at the bottom of the bottomless cone 3 through the rotary shaft 7; ...

Embodiment 2

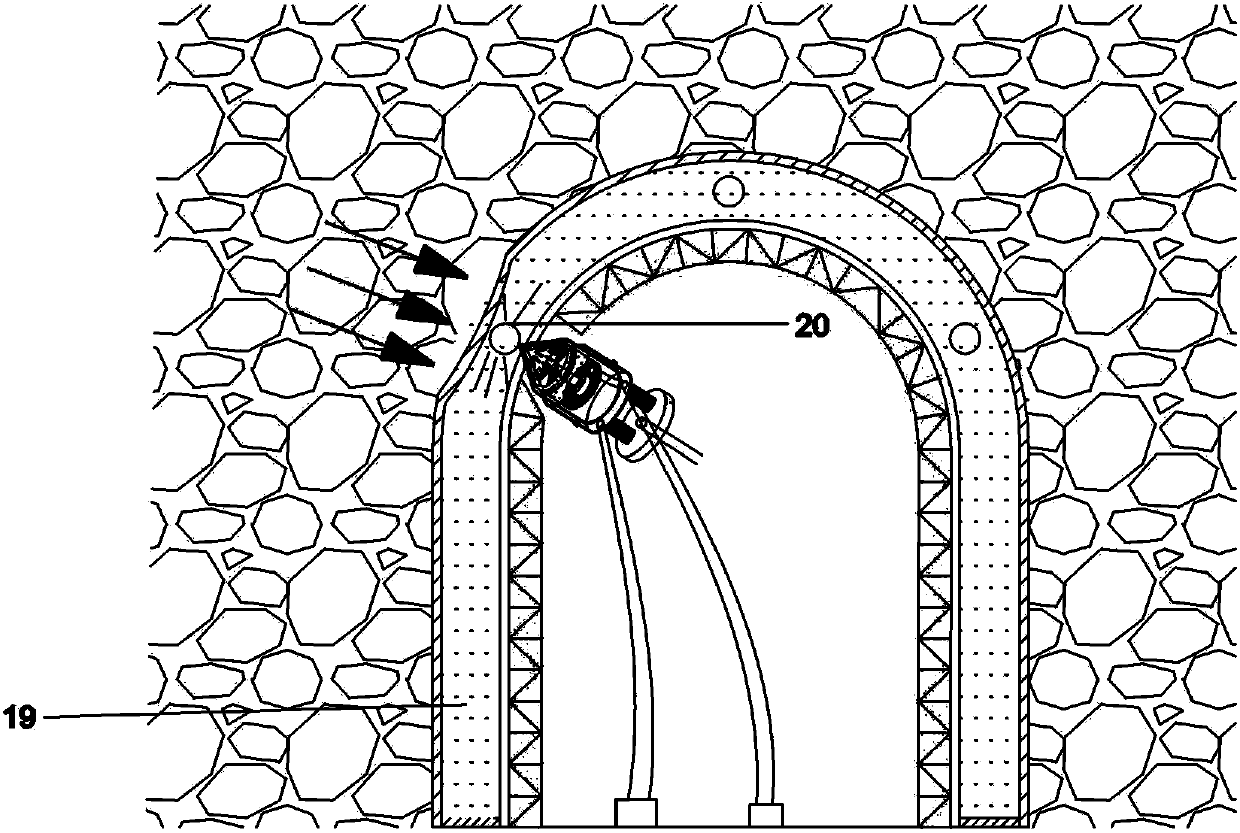

[0042] like figure 2 As shown, a method for using the above-mentioned device for tunnel fluid filling lining construction, the method comprising:

[0043] A suction hole 20 is reserved in the secondary lining steel arch; the fluid filling material 19 is squeezed and compressed with the deformation of the surrounding rock;

[0044] Turn on the air pump 10, and selectively fill the gas storage bin 2 with gas with the required pulse pressure according to the pressure data displayed by the pressure sensor in the fluid filling 19 filled between the primary lining and the secondary lining steel arch of the tunnel. The bottomless cone 3 is driven by the rotating motor 8 to rotate at a constant speed, so that the gas storage chamber 2 maintains a certain frequency to eject air pulses of the required intensity, and the fluid filling material 19 is filled through the channel formed by the gas storage chamber hole 5 and the metal shell hole 6 Carry out smashing; turn on the suction mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com