A Fault Diagnosis Method for Bearing Equipment

A fault diagnosis and equipment technology, applied in the fields of instrumentation, calculation, character and pattern recognition, etc., can solve the problems of ignoring the change of the sample distribution state, hindering the further application of the unbalanced processing method, and reducing the classification accuracy, so as to achieve accurate fault diagnosis. The effect of precision, fast and efficient incremental merge, and reliable diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

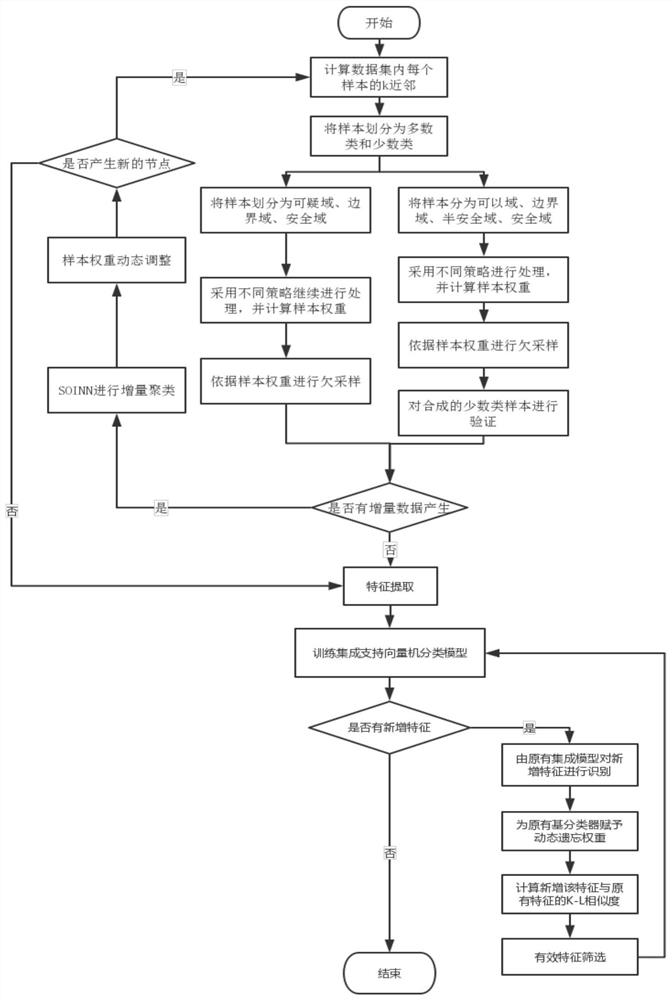

Method used

Image

Examples

Embodiment

[0126] 1. Data description

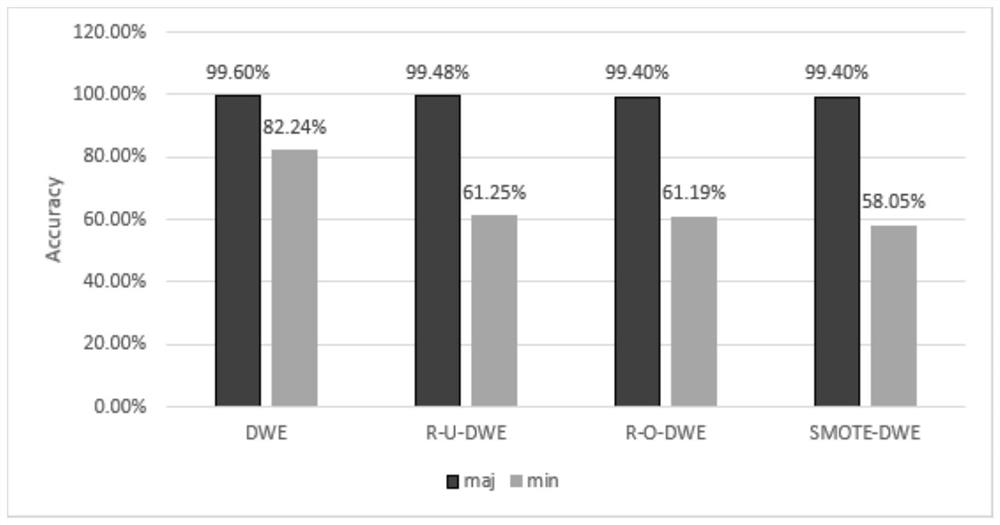

[0127] The experimental data is the bearing state data of the electrical engineering laboratory, with a total of 1,341,856 data points, and the bearing model is 6205-2RS JEM SKF deep groove ball bearing. Three single-point faults of fault levels were arranged on the inner ring, outer ring, and rolling elements on the bearing by using EDM technology, and the fault diameters were 0.007, 0.014, and 0.021 inches respectively. Select the vibration signals collected by the vibration sensor at the motor drive end under the normal state (N), inner ring fault (IRF), outer ring fault (ORF) and rolling element fault (BF), the sampling frequency is 12kHz, and the The original vibration signal uses the wavelet packet to decompose the energy value of each frequency band, and extracts appropriate parameter features to distinguish different categories. The analysis of the data samples shows that there is an imbalance between the normal data and the fault data, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com