Bearing fault mode diagnosis method and system for small sample data set

A technology of failure modes and diagnostic methods, applied in neural learning methods, electrical digital data processing, character and pattern recognition, etc., to avoid distribution inconsistencies and alleviate performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

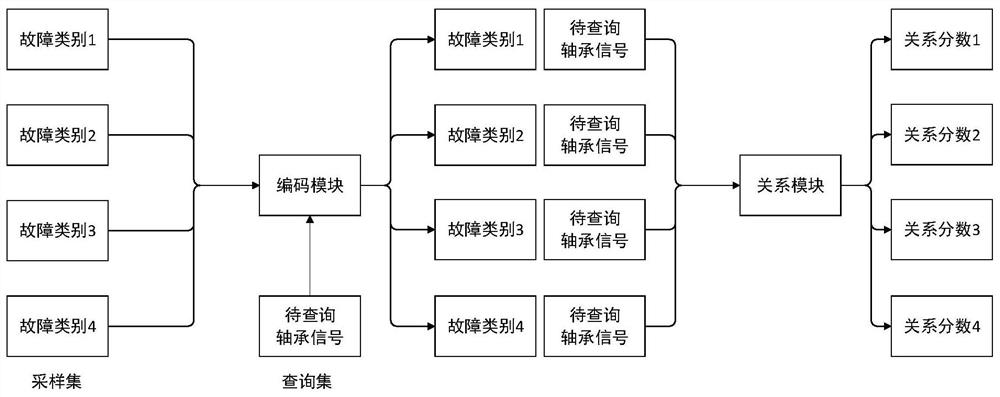

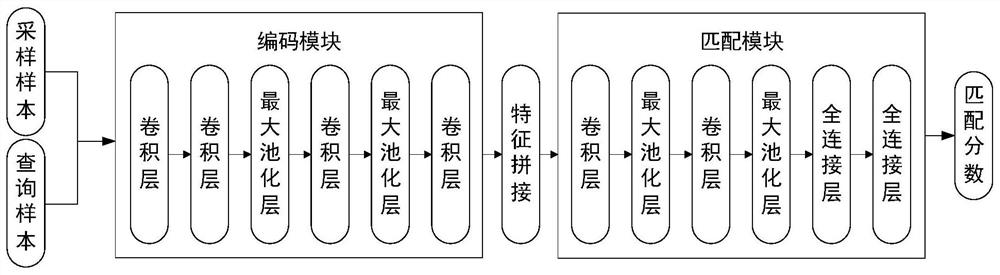

[0074] The present invention provides a bearing fault mode diagnosis method for small sample data sets, such as Figure 4 shown, including the following steps:

[0075] 1) The time-series signal of bearing vibration collected in this example has four different working conditions. Each working condition includes 10 bearing failure modes. In addition to normal, there are 9 failure types, including three different failures Location: inner race fault, ball fault and outer race fault, and each fault location has three different fault sizes.

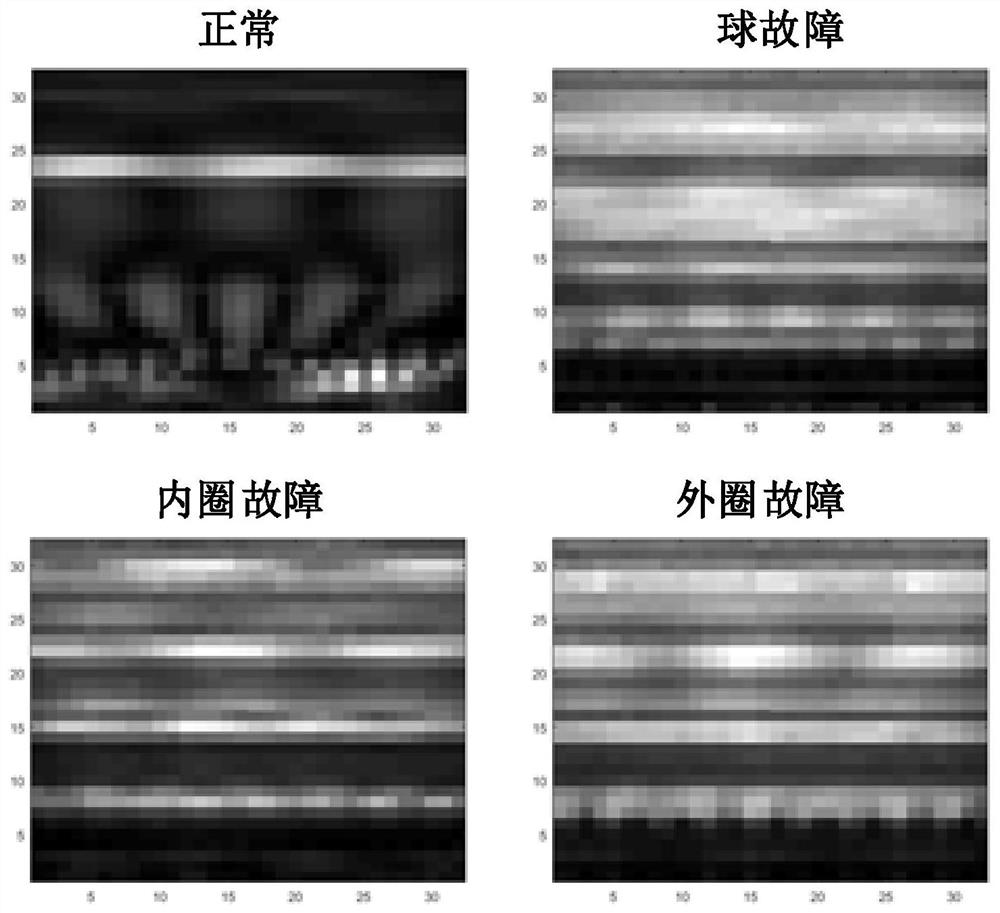

[0076] 2) After continuous wavelet transform and image grayscale of various types of bearing signals, a characteristic map of bearing faults is formed, some of which are as follows: figure 1 As shown, it is finally stored in the database of the server.

[0077] Step 2) specifically includes:

[0078] Step 201: The vibration data collected by the acceleration sensor is a one-dimensional continuous time series signal, and the signal is prepro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com