Solar cell lamination control device

A technology of solar cells and control devices, which is applied in the field of solar cells, can solve problems such as difficult to realize, and achieve the effects of improving flexibility, reducing investment costs, and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

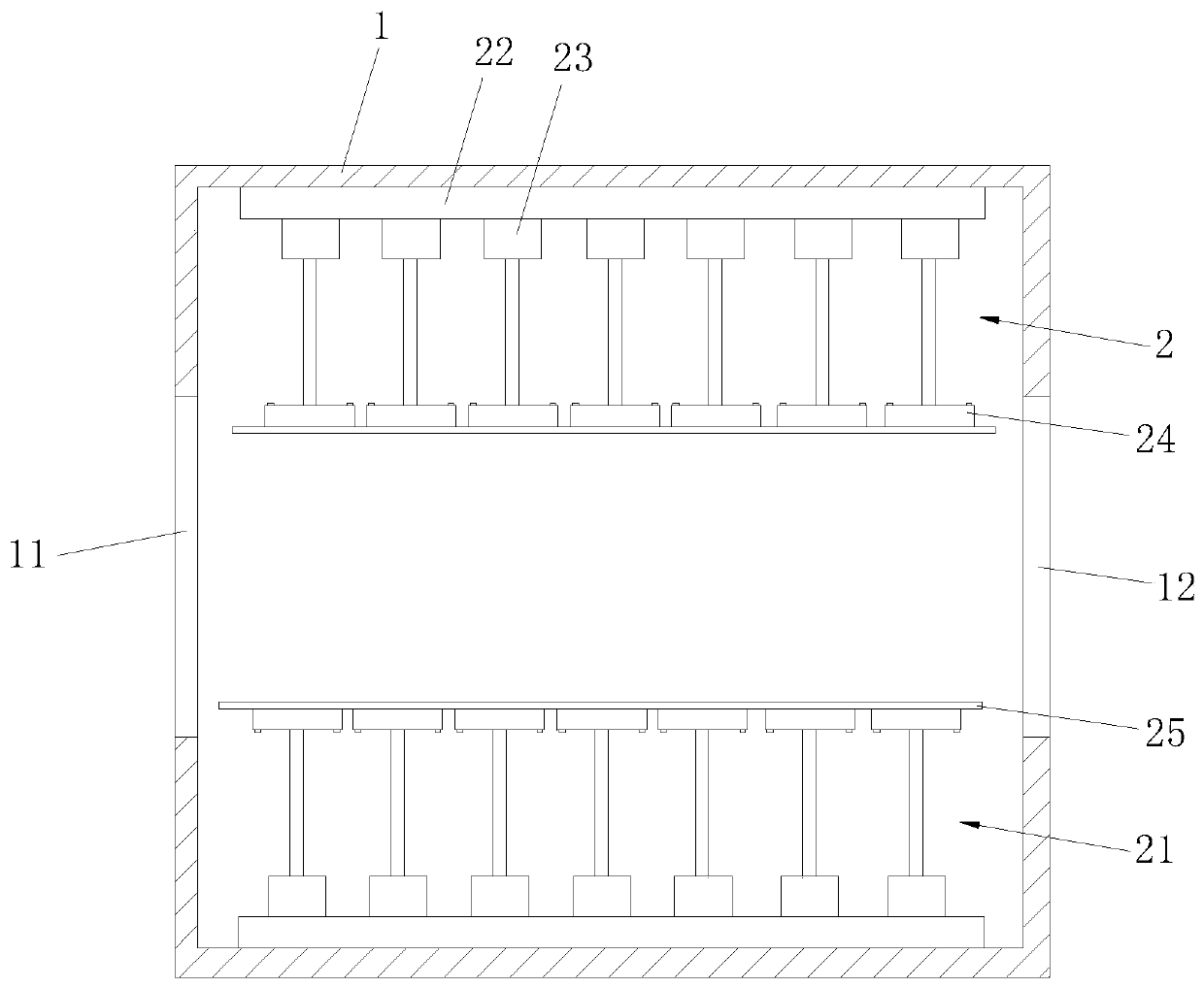

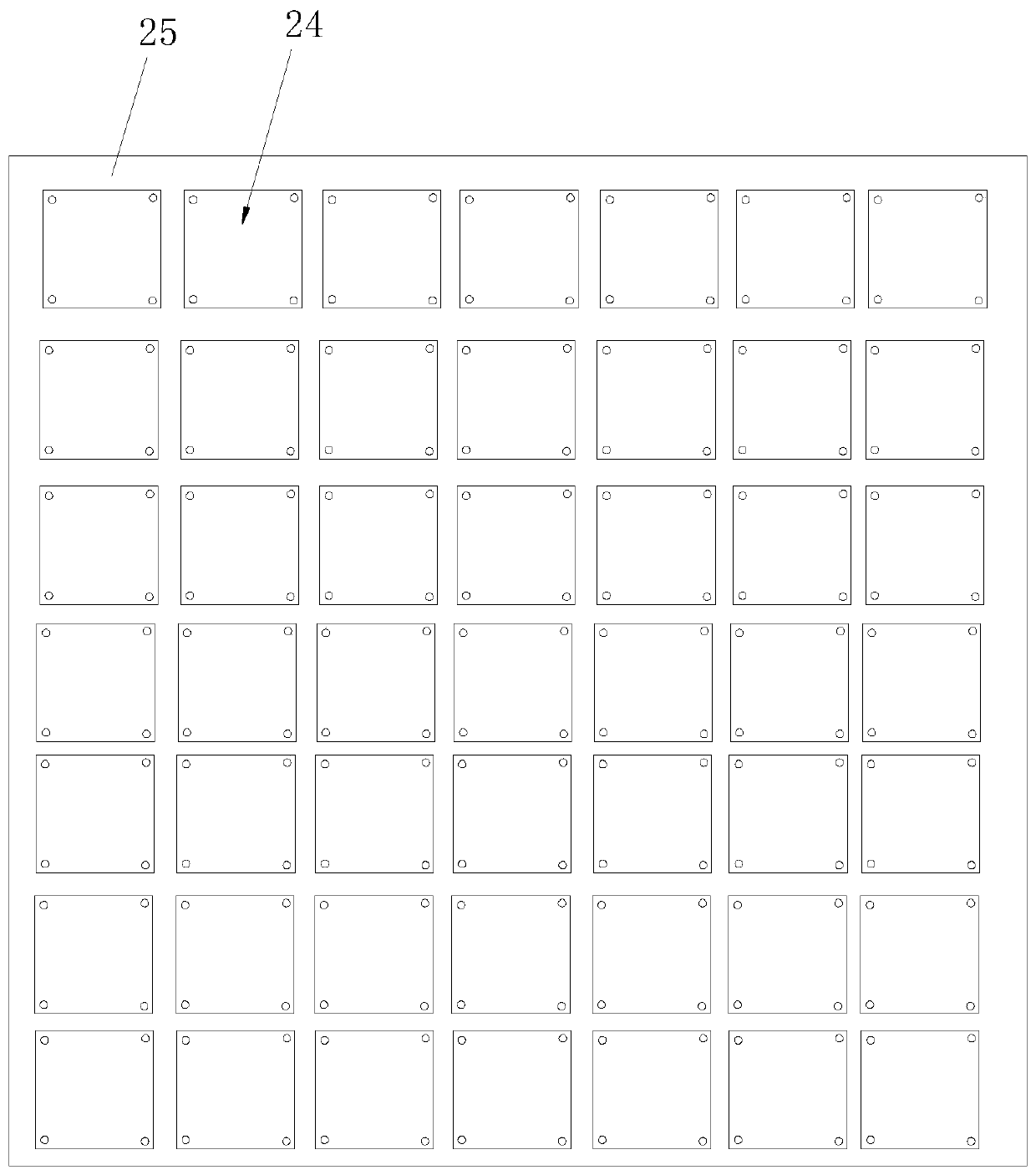

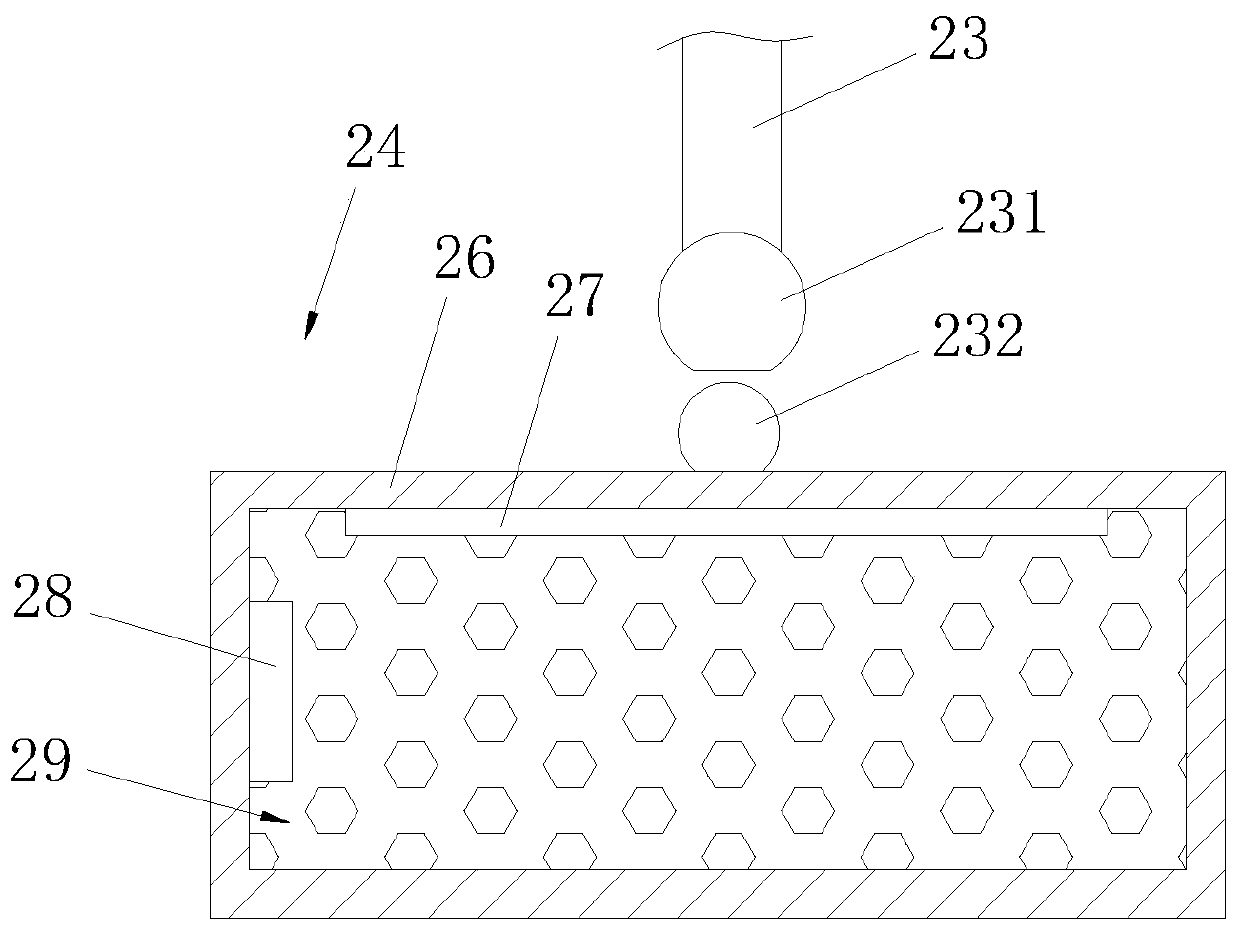

[0029] Example: A solar cell lamination control device, such as figure 1 versus Figure 4 As shown, the cabinet 1 and the host computer 3 are included. The symmetrical sides of the cabinet 1 are provided with an inlet 11 and an outlet 12 respectively. An upper laminate assembly 2 is installed on the inner top wall of the box body 1, a lower laminate assembly 21 is installed on the inner bottom surface of the box body 1, and the upper laminate assembly 2 and the lower laminate assembly 21 are arranged symmetrically. Both the upper lamination assembly 2 and the lower lamination assembly 21 include a base 22, a pressure pad 25 and a main controller 31. A plurality of vertically arranged driving cylinders 23 are arranged on the surface of the base 22, and the output shafts of the driving cylinders 23 correspond to each other. A heating element 24 is provided, and the pressure pad 25 is fixedly connected to the surface of the heating element 24 facing away from the driving cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com