Radix ophiopogonis combined harvester

A technology of combine harvester and Ophiopogon japonicus, which is applied to excavator harvesters, harvesters, and de-roofing machines, can solve problems such as low efficiency, high harvesting labor intensity, and research lag, so as to ensure harvest quality and reduce harvesting. The effect of soil content and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

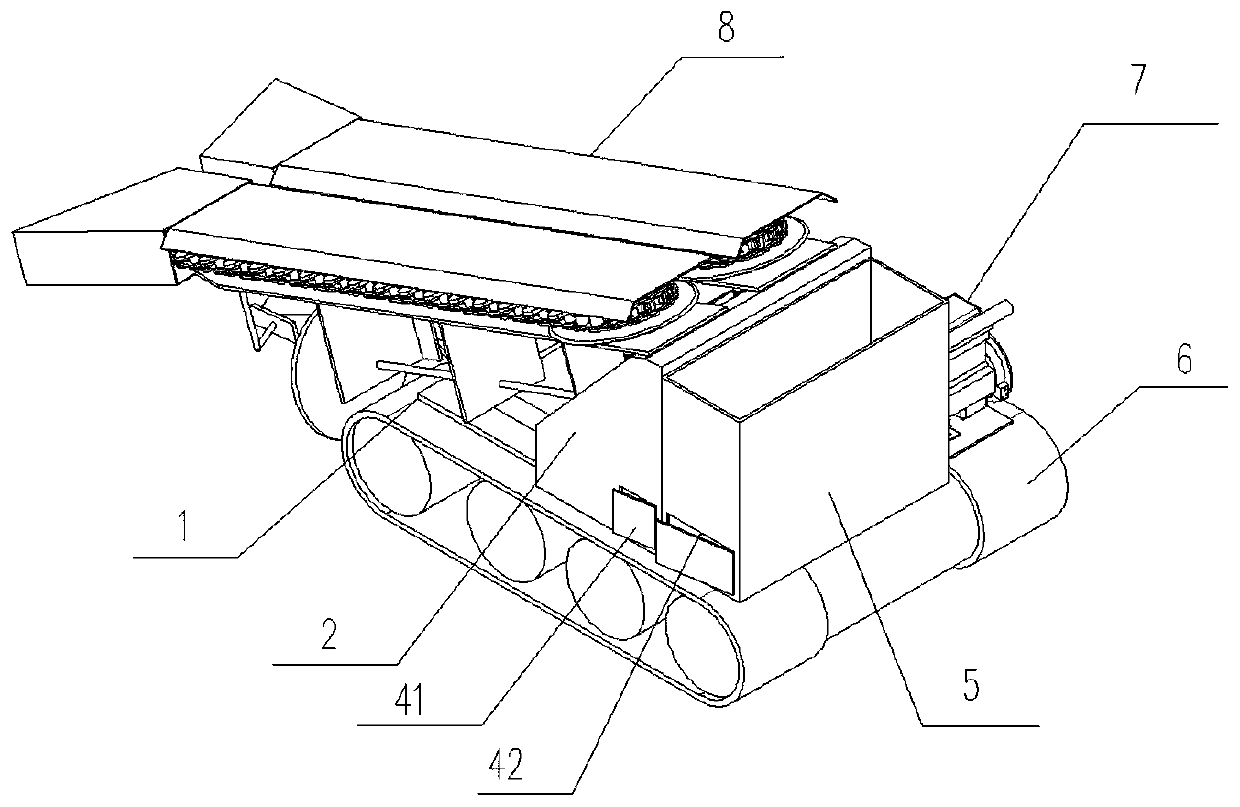

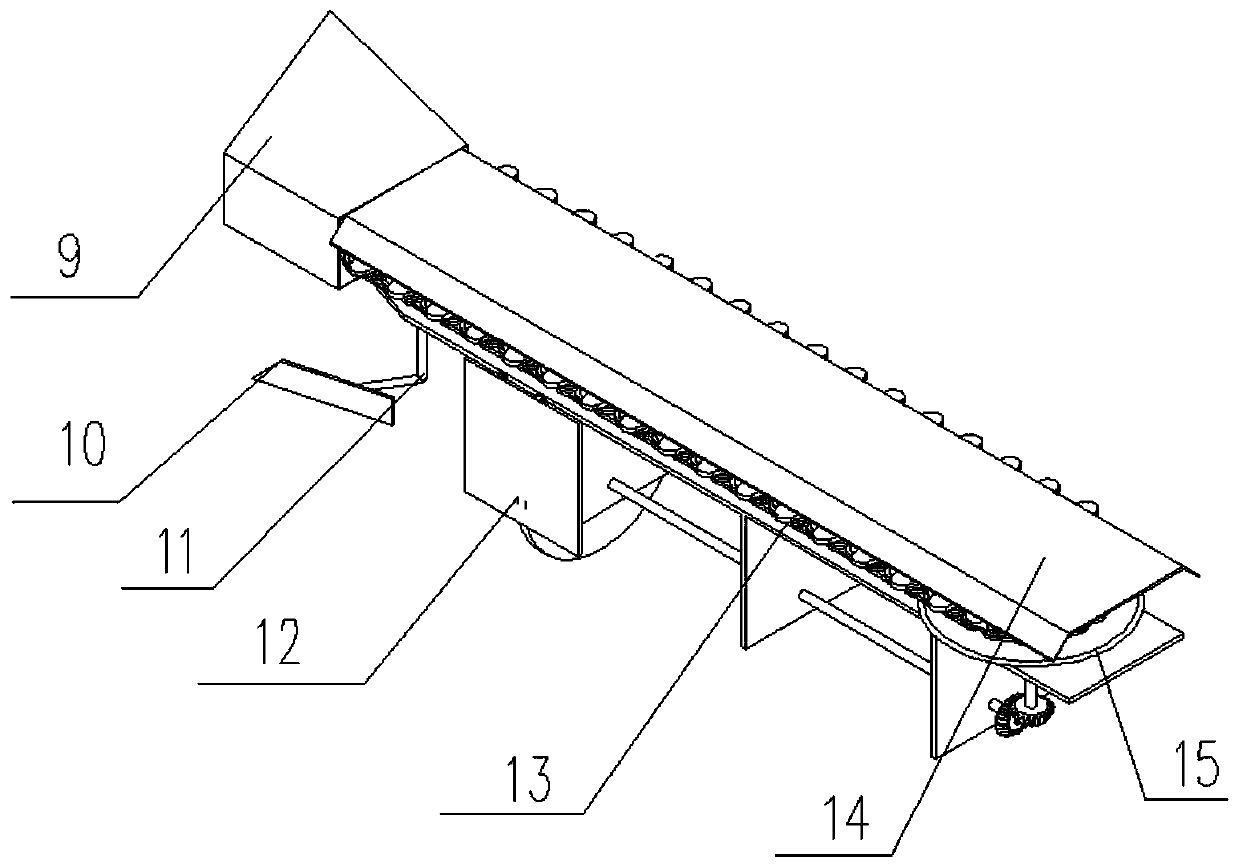

[0058] Such as figure 1 Shown, a kind of Ophiopogon japonicus combine harvester comprises frame 1, collecting device, crawler chassis 6, transmission device 7 and harvesting device 8.

[0059] Such as Image 6As shown, the frame 1 includes a plurality of angle steels 35, which are connected in sequence to form a rectangular frame 1, and fixed angle steels are added to the middle of the frame 1 for fixing to keep the frame stable.

[0060] The top rear portion of the frame 1 is provided with a collecting device. The collection device includes a tuber collection box 2 and a plant collection box 5; wherein the tuber collection box 2 is located in front of the plant collection box 5, and the front side of the tuber collection box 2 is an inclined plane. The side of tuber collection box 2 is provided with tuber collection box discharge opening 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com