Bottle

A bottle and bottle-shaped technology, applied in the direction of packaging food, packaging, medical containers, etc., can solve the problem of uneven liquid discharge, and achieve the effects of uniform liquid discharge, simple structure and improved sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

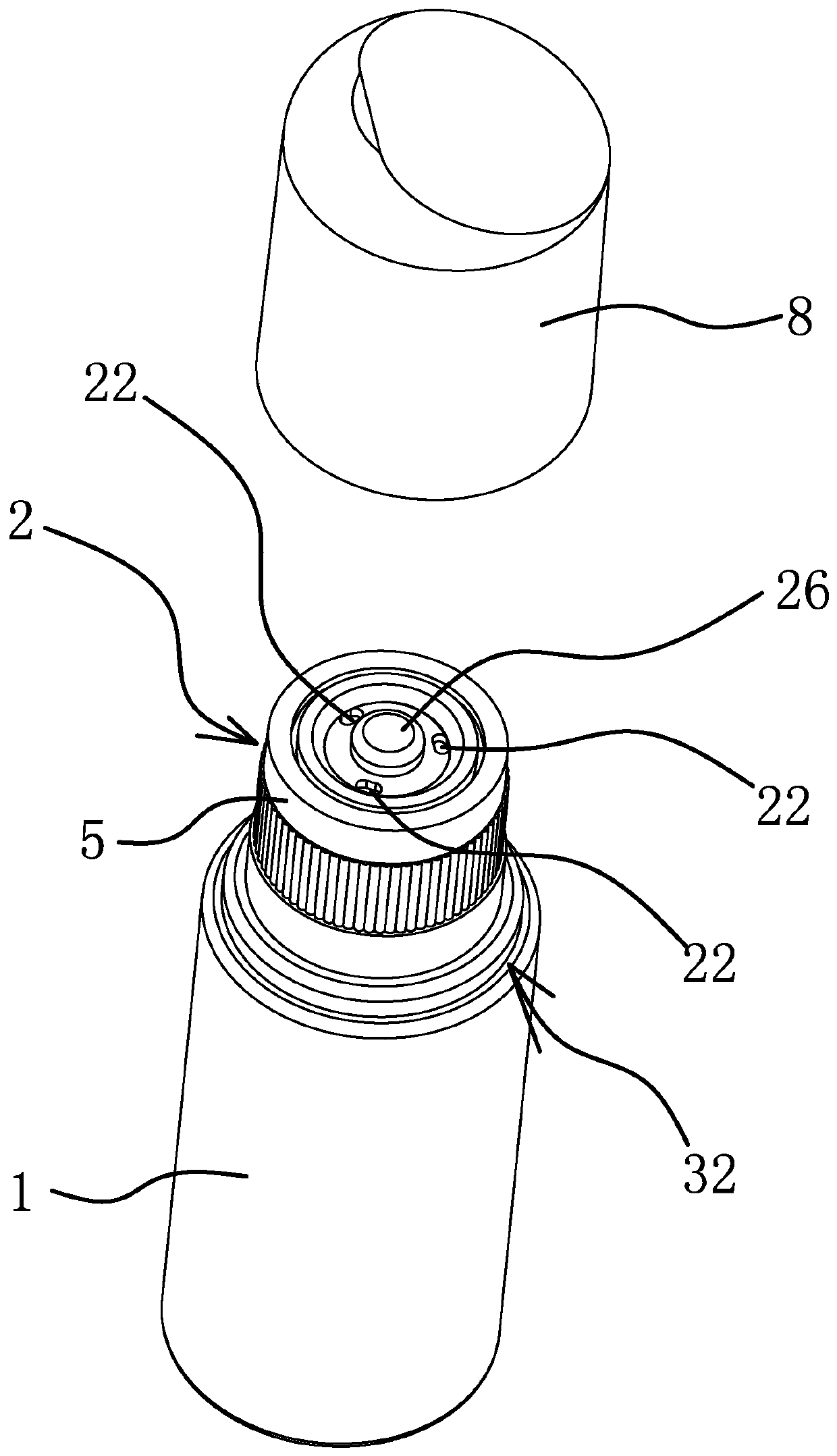

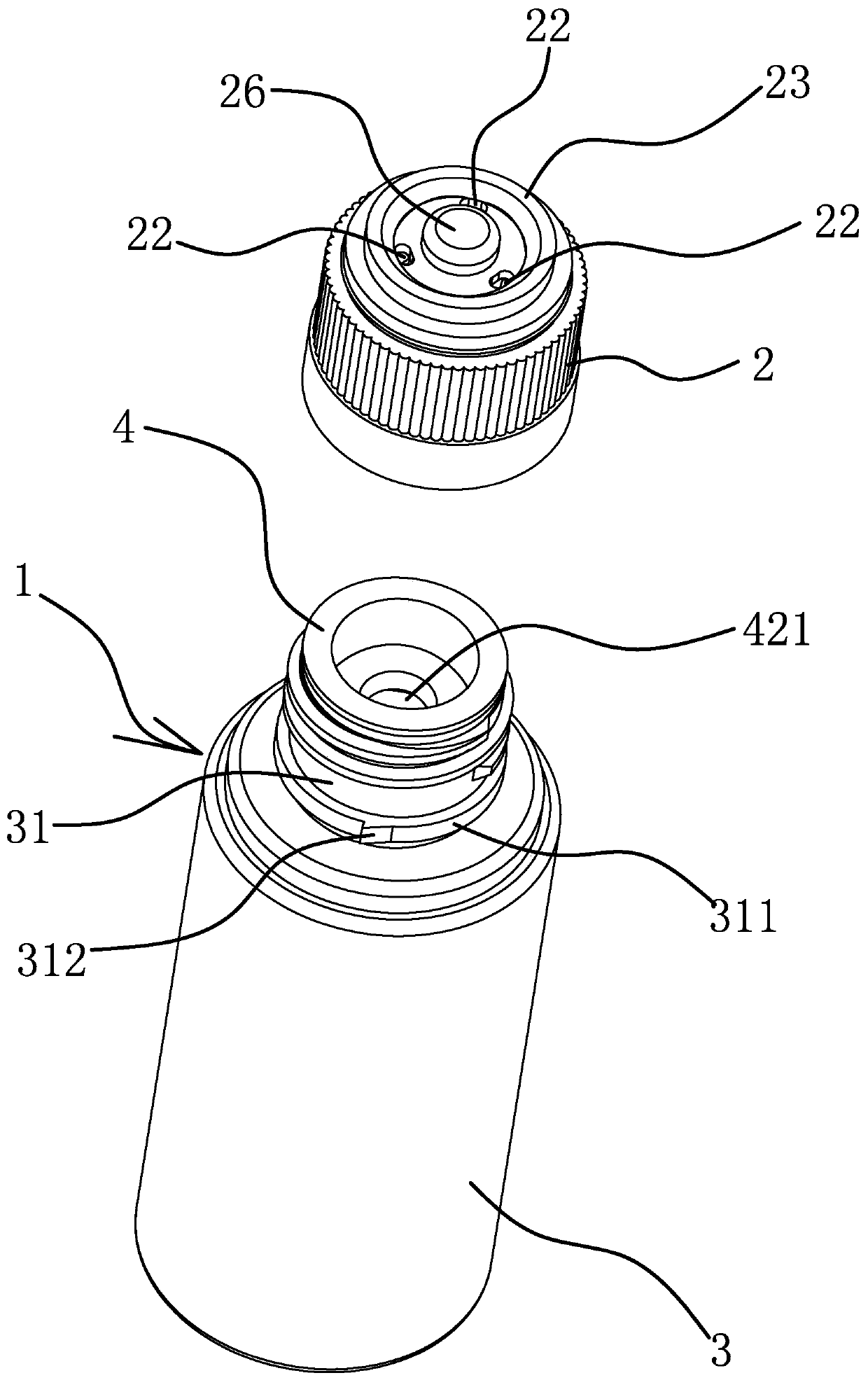

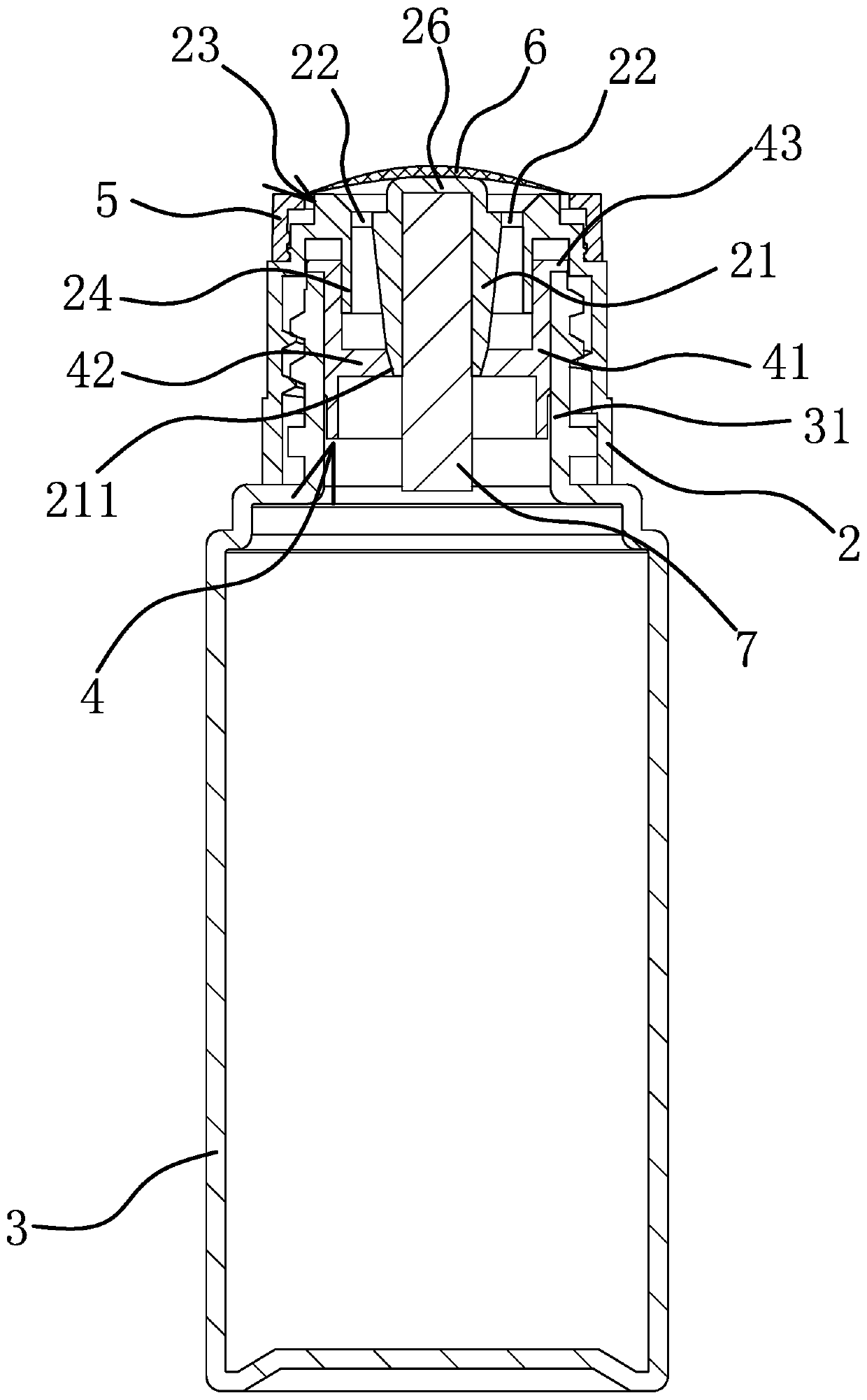

[0047] Such as Figure 1-Figure 3 As shown, a bottle includes a bottle-shaped body 1 and a rotatable inner cover 2 connected to the upper end of the body 1. The upper end of the body 1 is provided with a liquid hole 421 communicating with the inner cavity of the body 1. When the inner cover 2 rotates, it can Move up and down to open or close the liquid hole 421 , and a limiting structure capable of limiting the rotation angle of the inner cover 2 is provided between the inner cover 2 and the main body 1 . In this embodiment, the body 1 specifically includes a bottle body 3 with a mouth 31 and a bottle stopper 4 fixed in the mouth 31 , a liquid hole 421 is provided inside the bottle stopper 4 , and an inner cap 2 is connected to the outside of the mouth 31 The outer side of the bottle body 3 is provided with an annular socket 32 below the mouth 31, and the bottle also includes a bottle cap 8 that can be placed on the annular socket 32 and cover the inner cap 2.

[0048] Su...

Embodiment 2

[0063] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the position-limiting structure includes a protruding column arranged outside the mouth 31 and a spiral guide groove arranged inside the inner cover 2, The boss is located in the spiral guide groove and can move along the spiral guide groove. The cooperation between the boss and the threaded guide groove enables the inner cover 2 to move up or down while turning, and at the same time, the inner cover 2 is restricted when the boss moves along the spiral guide groove until it abuts against the inner walls at both ends of the spiral guide groove Turning, the inner cap 2 reaches the maximum distance of upward or downward movement, which can prevent the inner cap 2 from completely detaching from the mouth portion 31 and invalidate the entire structure of the bottle.

Embodiment 3

[0065] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that in this embodiment, the outer diameter of the annular convex portion 24 is smaller than the inner diameter of the cylindrical body 41, and a sealing ring is provided on the inner side of the upper end of the cylindrical body 41, and the inner side of the sealing ring is The wall abuts against the outer side wall of the annular protrusion 24 to form a seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com