Device, system and method for generating micro-droplets

A technology for generating device and micro-droplets, applied in the field of dispensing and measuring micro-liquids, can solve problems such as small volume error, and achieve the effect of controllable volume error and easy generation of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

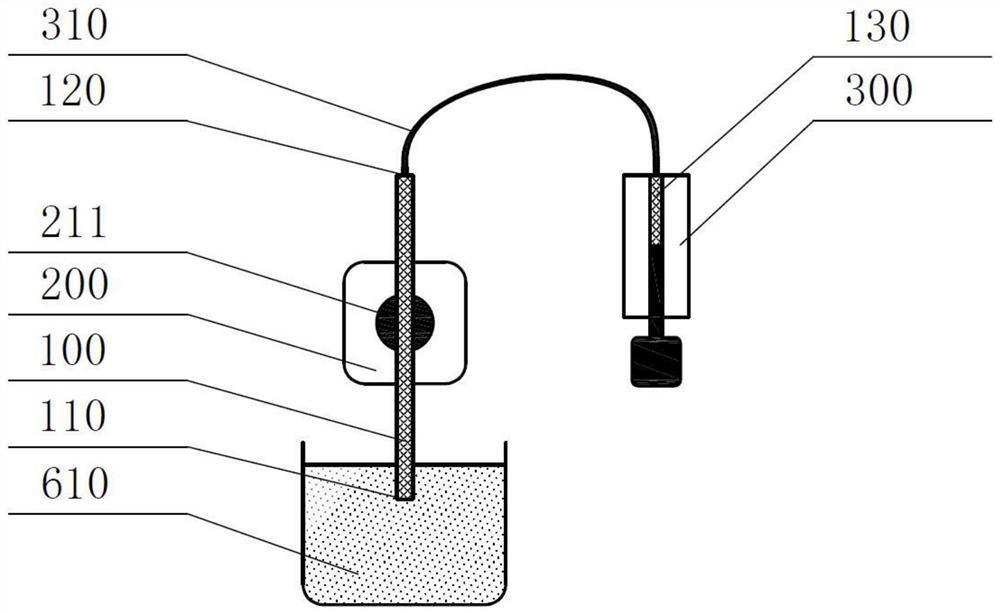

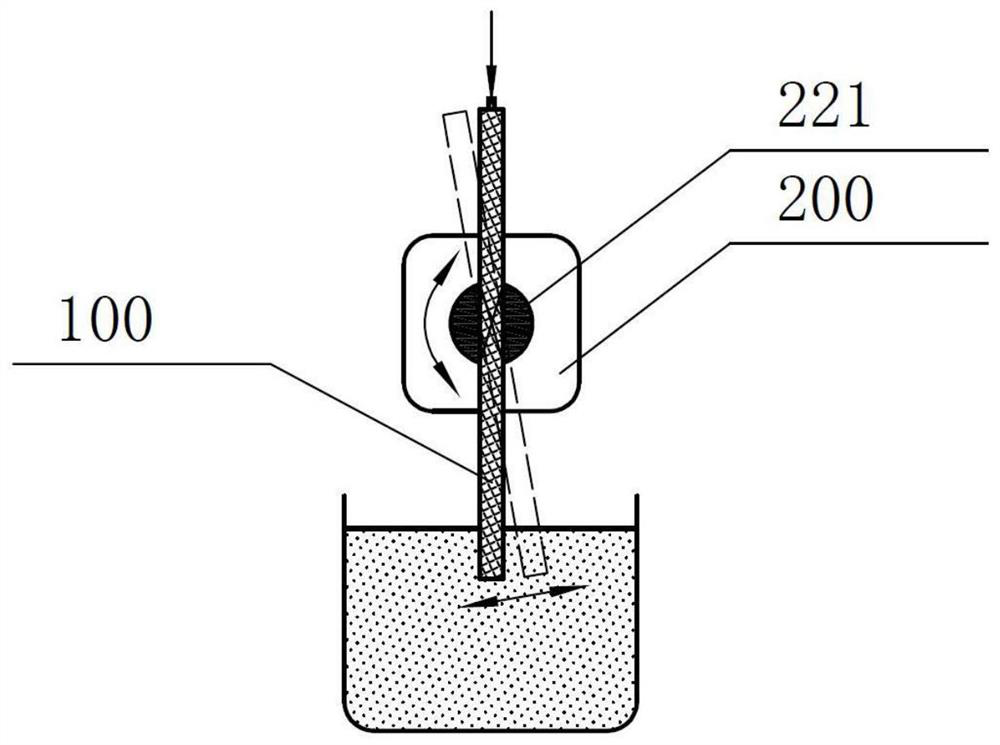

[0124] The microduct 100 is made of a non-rigid polypropylene material with a hardness of Shore D42. The inner diameter of the first opening 110 of the micropipe 100 is 150 microns, the outer diameter is 300 microns, and the length of the vibration radius is 6 cm. The vibration frequency of the rotary vibration mechanism 200 is 100 Hz, and the vibration amplitude voltage is 700 mVpp. The amplitude of the first opening 110 of the microchannel 100 is 0.1 mm.

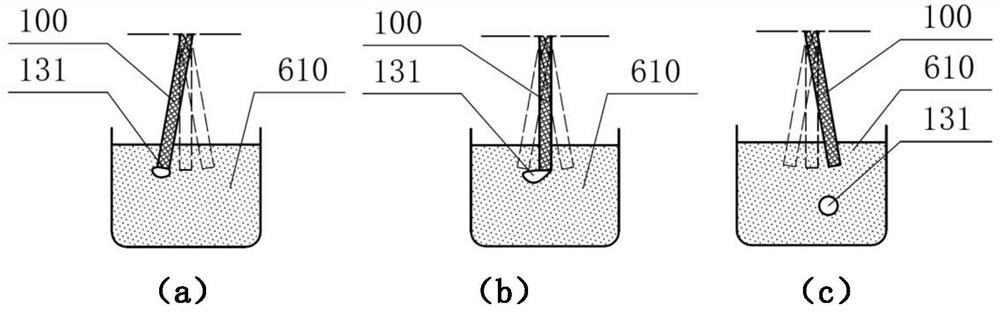

[0125] The first opening 110 of the micropipe 100 is connected with the fluid drive mechanism 300 through the joint 230 and the capillary 310; Insert below the liquid surface of the second liquid 610 at an included angle of 30 degrees, so that the vertical distance from the center of the nozzle of the first opening 110 of the micropipe 100 to the liquid surface of the second liquid 610 is 1.5mm, and push the fluid drive mechanism 300 The syringe 350 in the cavity pushes the first liquid 130 in its chamber to the nozzle o...

Embodiment 2

[0127] The micropipe 100 is made of stainless steel. The first opening 110 has an inner diameter of 60 microns, an outer diameter of 200 microns, and a vibration radius of 5 cm. The vibration frequency of the rotary vibration mechanism 200 is 100 Hz, and the vibration amplitude voltage is 400 mVpp. The amplitude of the first opening 110 of the microchannel 100 was 1 mm.

[0128] The second opening 120 of the micropipe 100 is connected to the fluid drive mechanism 300 through the joint 230 and the capillary 310; the first opening 110 of the micropipe 100 is inserted into the second liquid at an angle of 90 degrees to the liquid surface of the second liquid 610 610 below the liquid level, so that the vertical distance from the nozzle center position of the first opening 110 of the microchannel 100 to the liquid level of the second liquid 610 is 1.5 mm, and the syringe 350 in the fluid drive mechanism 300 is pushed to move the second liquid 610 to the second liquid in its cavity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com