Microporous membrane material preparation method, microporous membrane material and application thereof

A microporous film and electrodeposition technology, applied in electrolytic organic material plating, electrolytic inorganic material plating, electroforming, etc., can solve the problems of difficult preparation of microporous film materials, low preparation repeatability, low relative density, etc. And the morphology is precise and controllable, the preparation repeatability is high, and the edge is neat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The first aspect of the present invention provides a method for preparing a microporous membrane material by electrodeposition, wherein the method includes:

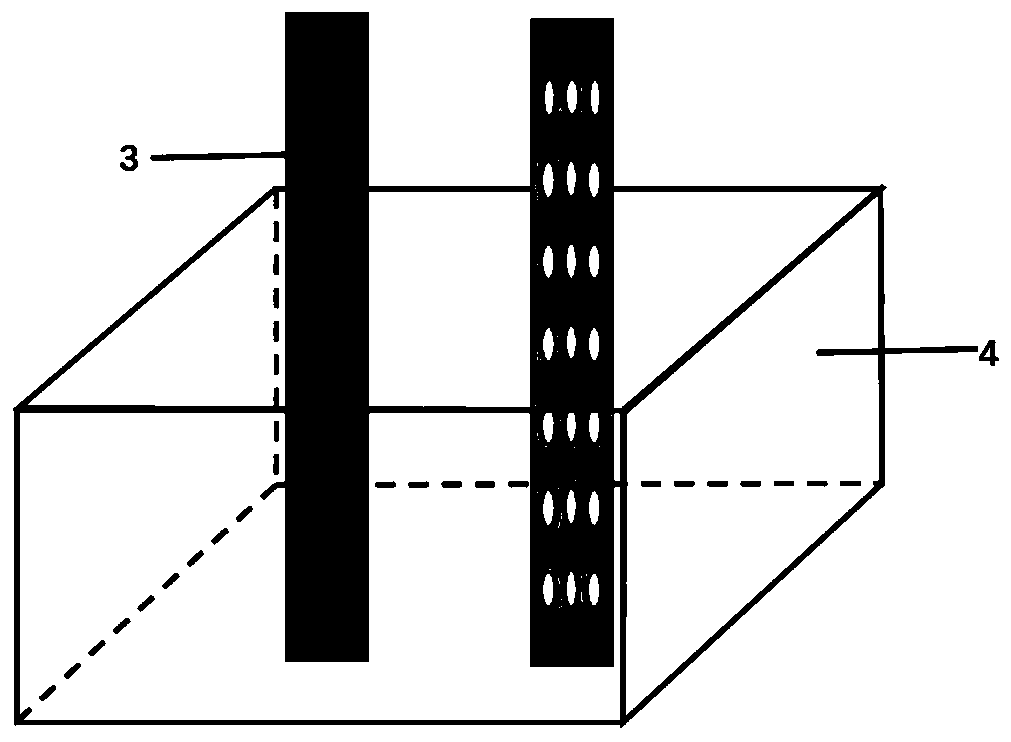

[0022] (1) form a non-conductive micro-lattice on the electrode, and form the electrode with the non-conductive micro-lattice as a template;

[0023] (2) placing the template in the electrolyte as a working electrode for electrodeposition, and forming a film-like deposition layer in the region where the micro-lattice does not exist on the template; and

[0024] (3) peeling off the film-like deposition layer.

[0025] According to the present invention, in step (3), the film-like deposition layer is peeled off, and the peeled-off film-like deposition layer is called a microporous membrane material.

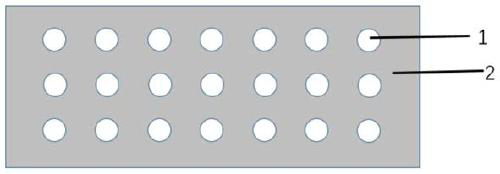

[0026] According to the present invention, firstly, a non-conductive micro-lattice array can be formed on the electrode. In the present invention, as figure 1 as shown, figure 1 It is a schematic diagram of an elec...

Embodiment 1

[0060] This example is to illustrate the microporous membrane material prepared by the method of the present invention.

[0061] (1) Use inkjet printing technology to print polystyrene dot matrix on the titanium electrode, adjust the ink concentration and printing parameters, control the diameter of the circle of the deposition area after the ink droplet is dried to be 100 μm, and the center distance of the ink droplet to be 500 μm. The matrix distribution is 10×10, and the thickness of the formed polystyrene micro-lattice is 5 μm and the electrode formed with the polystyrene micro-lattice is used as a template;

[0062] (2) A titanium electrode (template) formed with polystyrene microlattice is used as a working electrode, another untreated platinum electrode is used as a counter electrode, and a calomel electrode is used as a reference electrode, and the electrochemical deposition is carried out by a constant potential method; Among them, the electrolyte composition is CuSO ...

Embodiment 2

[0068] This example is to illustrate the microporous membrane material prepared by the method of the present invention.

[0069] (1) Prepare a metal hollow mask, wherein the hole diameter of the hollow area is 10 μm, the hole spacing is 50 μm, and the hole distribution is 100×100; the metal hollow mask is covered on the surface of the carbon cloth, and then sprayed with polytetrafluoroethylene Spraying; carbon cloth electrode area is 4cm 2 ; The unmasked area on the surface of the carbon cloth forms a dense polytetrafluoroethylene film, while the covered area is still carbon cloth;

[0070] (2) With the carbon cloth (template) that is formed with polytetrafluoroethylene micro-lattice as working electrode, platinum electrode is counter electrode, adopts cyclic voltammetric deposition method to carry out electrodeposition; Wherein, electrolyte composition is aniline (0.1mol / L), sulfuric acid (0.5mol / L). At a deposition voltage of -0.2V and a temperature of 20°C, a cyclic volt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com