Online ceramic ink jetting machine sprayer rapid cleaning facility and method

A ceramic inkjet and nozzle technology, which is applied to cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problem of high cost of production enterprises, no online cleaning of nozzles, high labor costs and time costs, etc. problems, to achieve the effect of reducing the cost of production enterprises, avoiding labor costs and time costs, and restoring normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

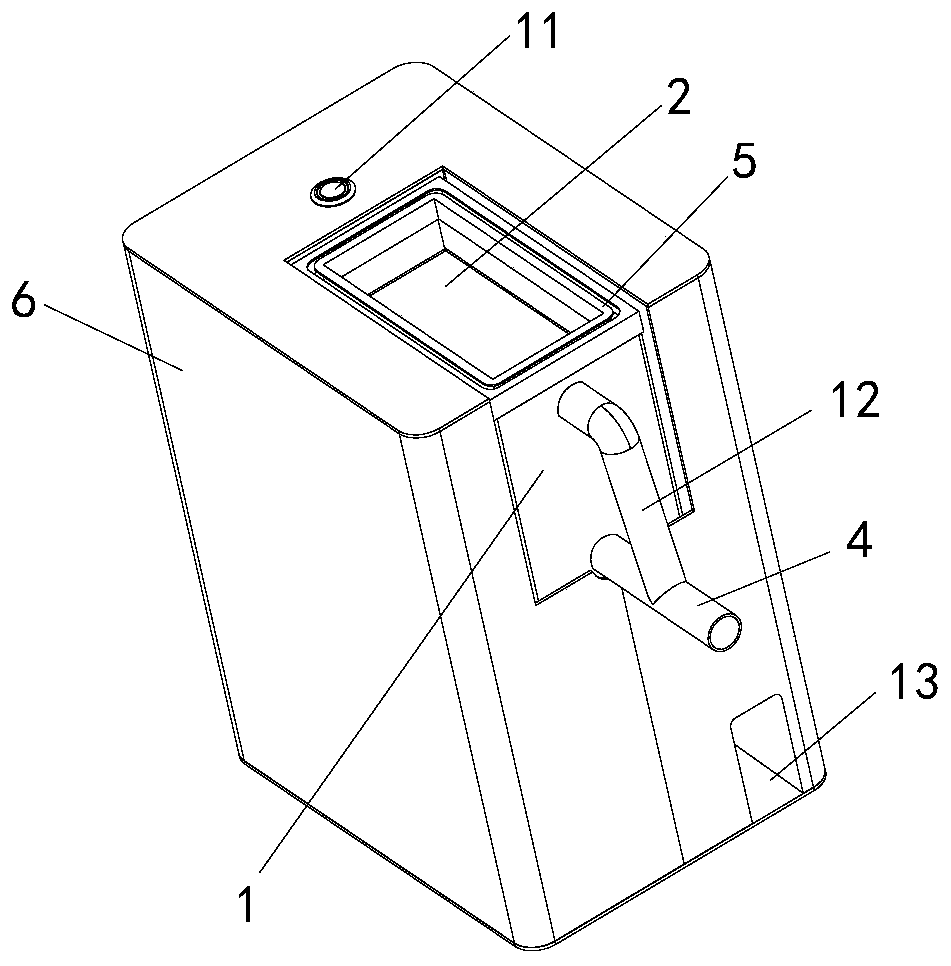

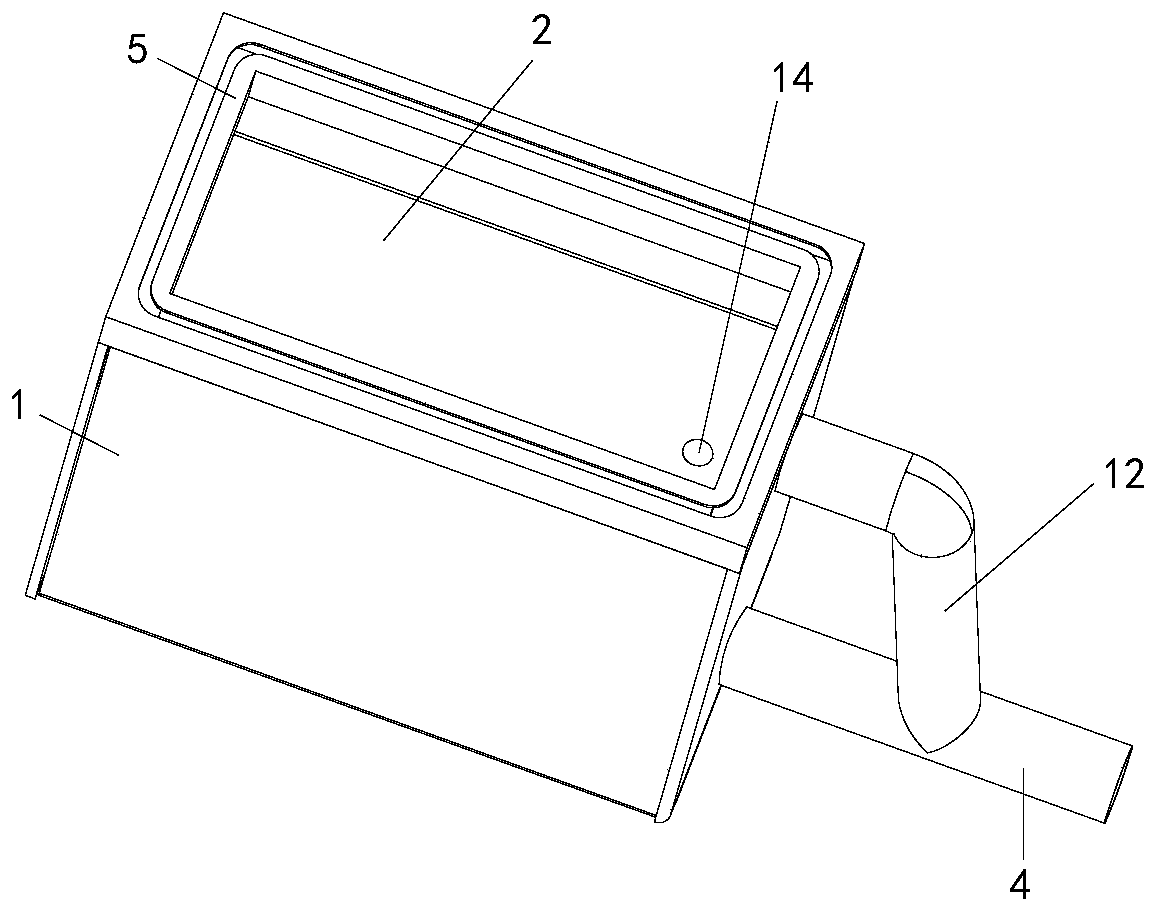

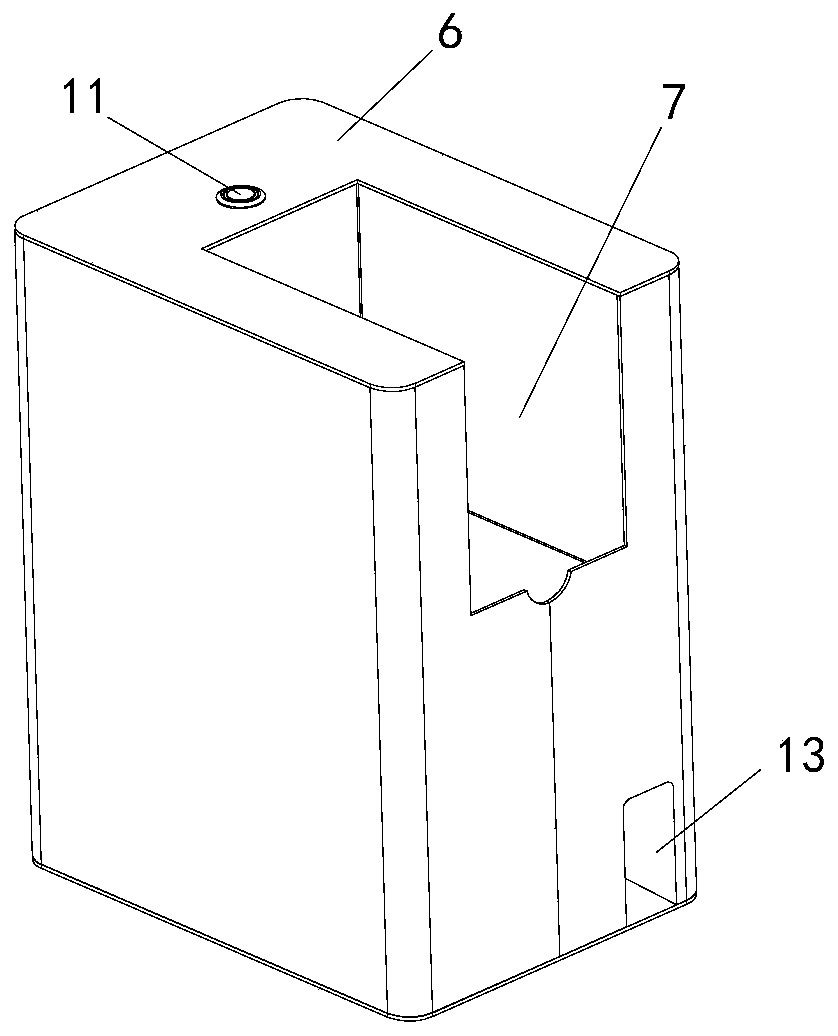

[0036] The invention provides a quick cleaning device for the nozzle head of an online ceramic inkjet machine, including a cleaning mechanism and a control device; wherein,

[0037] Described cleaning mechanism comprises housing 1, and the top of described housing 1 is provided with cleaning tank 2, and the notch profile of described cleaning tank 2 is compatible with the ceramic ink-jet nozzle that needs cleaning; The bottom is provided with an ultrasonic generator 3, and the cleaning tank 2 is also connected with a liquid inlet pipe 4;

[0038] The ultrasonic generator 3 is electrically connected with the control device.

[0039] The equipment for quickly cleaning the nozzle head of the online ceramic inkjet machine provided by the present invention can be used in the interval (1min-2min) when the inkjet machine stops printing. Eliminate the time-consuming operation of personnel, avoid spending a lot of labor and time costs, and solve the problem of nozzle clogging at the f...

Embodiment 2

[0051] The present invention provides a method for quickly cleaning the nozzle of an online ceramic inkjet machine, which adopts the above-mentioned equipment for quickly cleaning the nozzle of an online ceramic inkjet machine, and the specific cleaning steps are:

[0052] (1) Set the cleaning tank 2 in the above-mentioned equipment for quick cleaning of the nozzle head of the online ceramic inkjet machine on the blocked nozzle of the ceramic inkjet machine; Join, then operate step (1);

[0053] (2) Press the control button 11, open the ultrasonic generator 3 and the liquid inlet pump 9 through the control device, and clean the blocked nozzle of the ceramic inkjet machine through the cleaning liquid in the cleaning tank 2 and the ultrasonic generator 3, and the cleaning time 1min-2min;

[0054] (3) After a clogged nozzle is cleaned, press the control button 11 again, turn off the ultrasonic generator 3 and the liquid inlet pump 9 through the control device, and remove the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com