Automatic charging and discharging system of disc binder

A technology of automatic loading and unloading and perfect binding machine, which is applied in the direction of binding adhesive, book cover, book binding, etc., which can solve the problems of low operation efficiency and achieve the goals of improving production efficiency, accurate position, and saving human resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

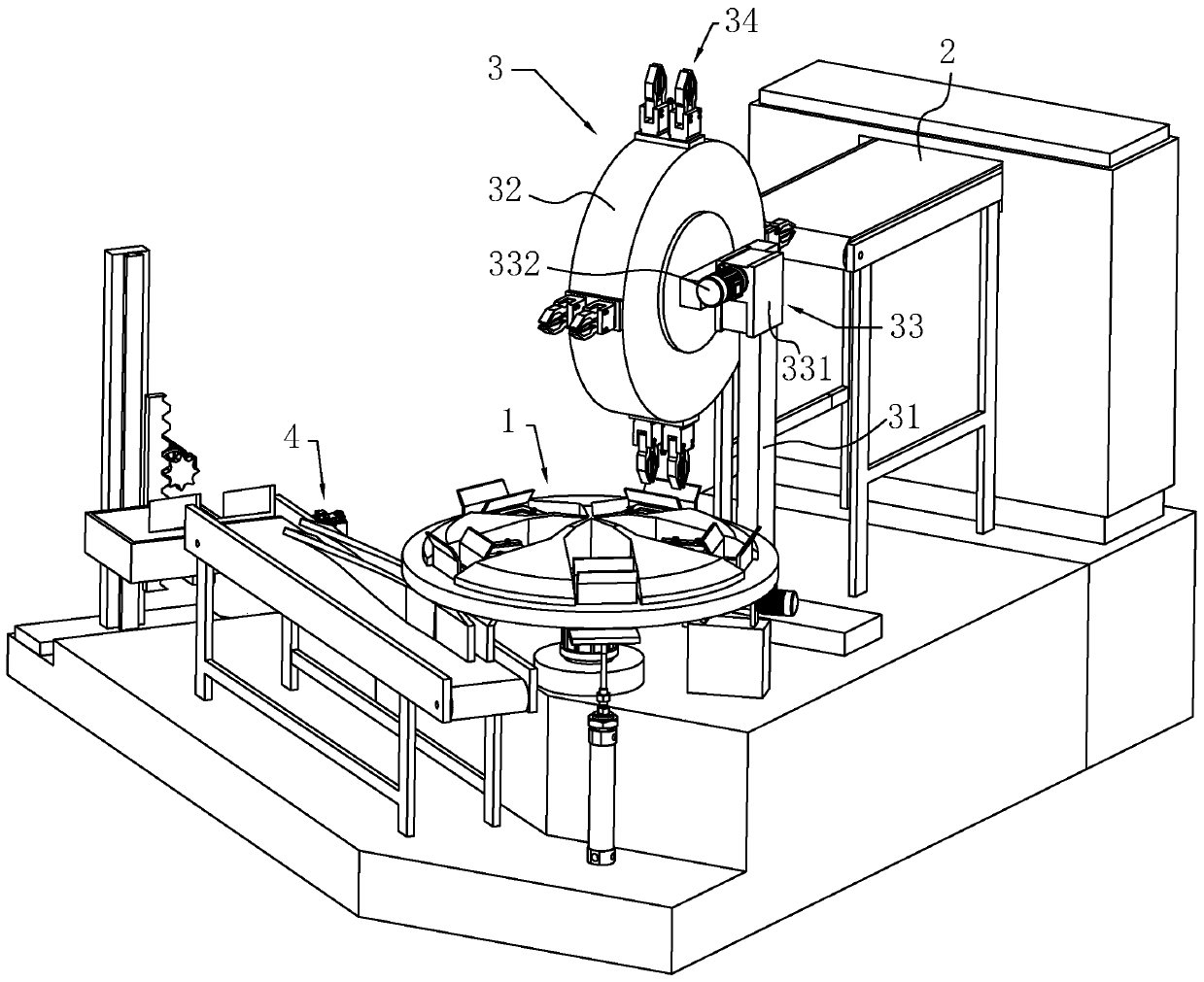

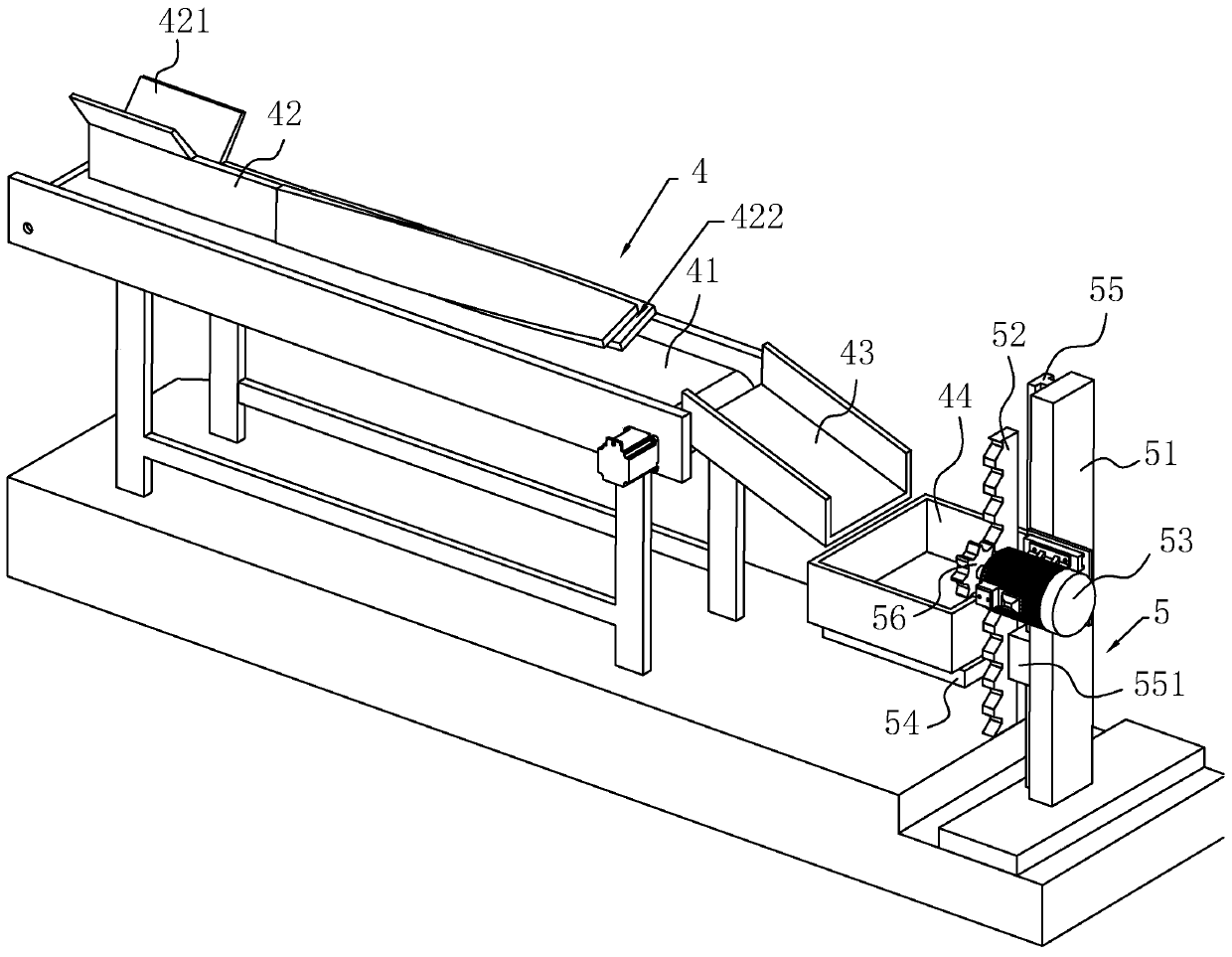

[0034] refer to figure 1, is an automatic loading and unloading system of a disc perfect binding machine disclosed in the present invention, comprising a disc perfect binding machine body 1, a first conveyor belt 2 that is docked with the binding device and used to transport the inner pages of books, and one side is connected with the second A conveyor belt 2 is docked, the other side is docked with the perfect disc binder body 1 , and the unloading component 4 is arranged on one side of the disc perfect binder body 1 .

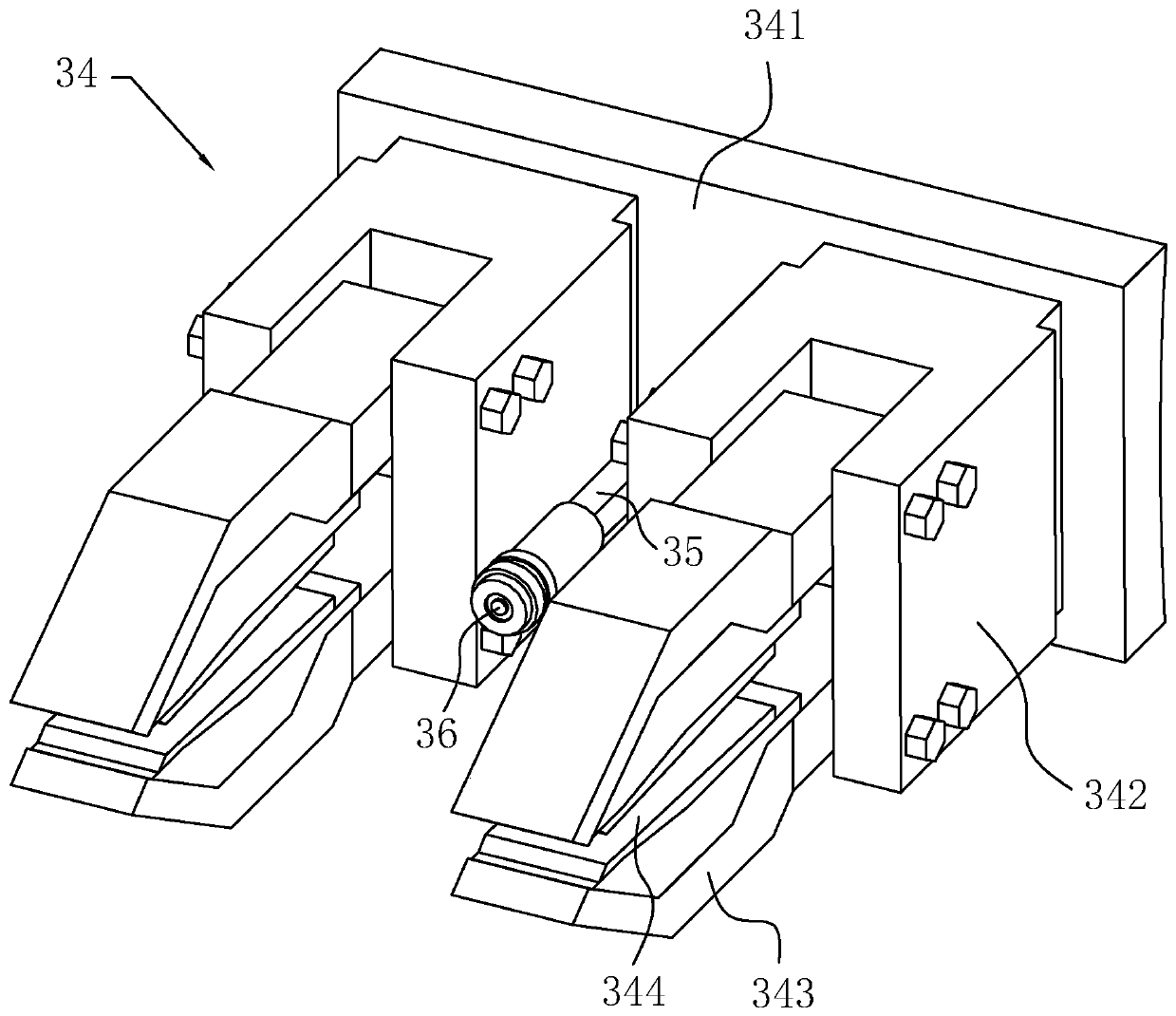

[0035] refer to figure 1 , the feeding assembly 3 includes a first frame 31, a rotating wheel 32 arranged on the first frame 31, a rotating drive member 33 for driving the rotating wheel 32, and a plurality of clamps arranged along the peripheral wall of the rotating wheel 32 The clamping parts 34, the number of groups of the clamping pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com